Treatment device for pickling and phosphating metal parts, and treatment method, and treatment plant for coating the metal parts

A technology for processing equipment and metals, applied in the field of metal bodies, can solve problems such as material failure, and achieve the effect of avoiding induration, not damaging welding ability, and significantly protecting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

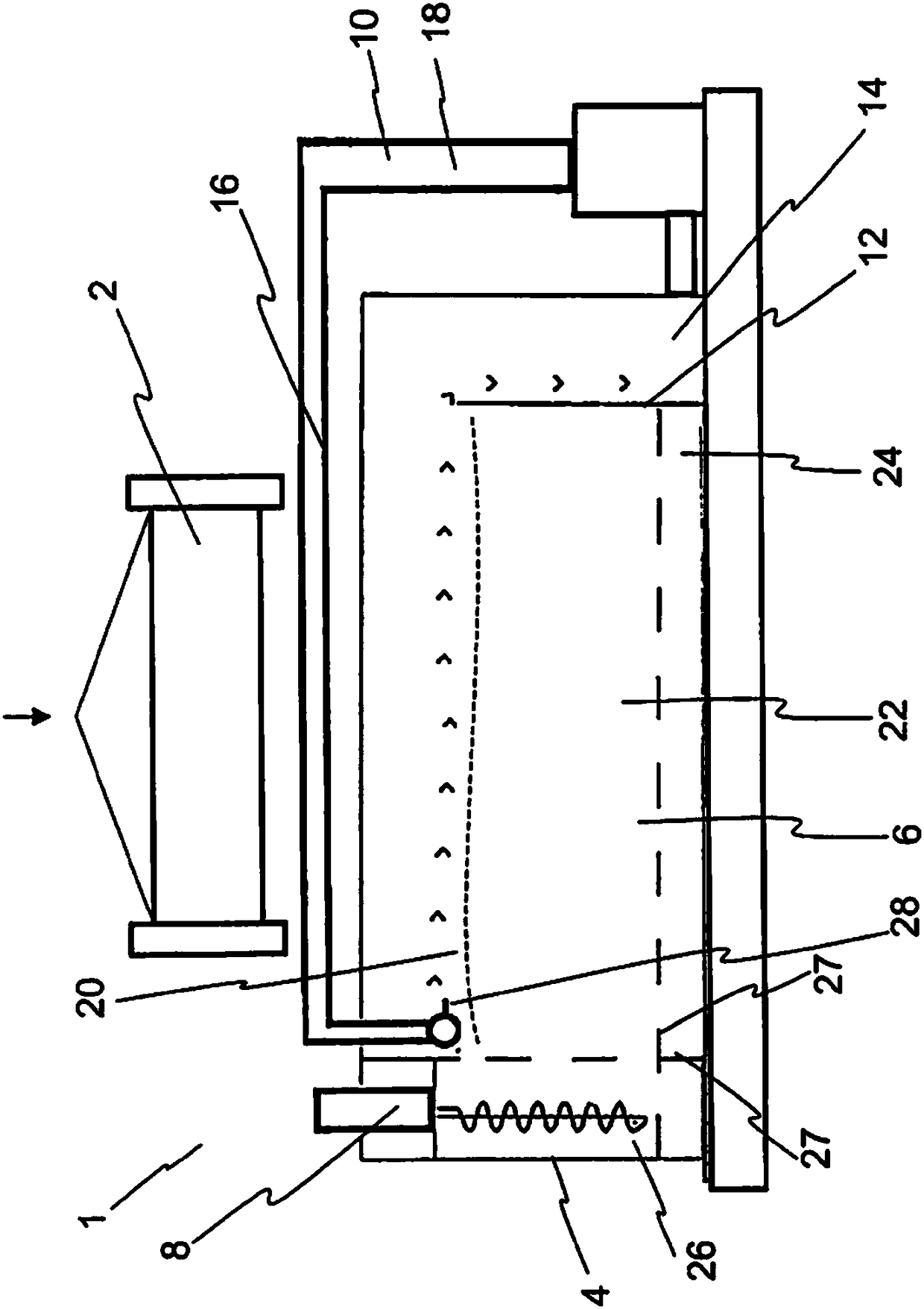

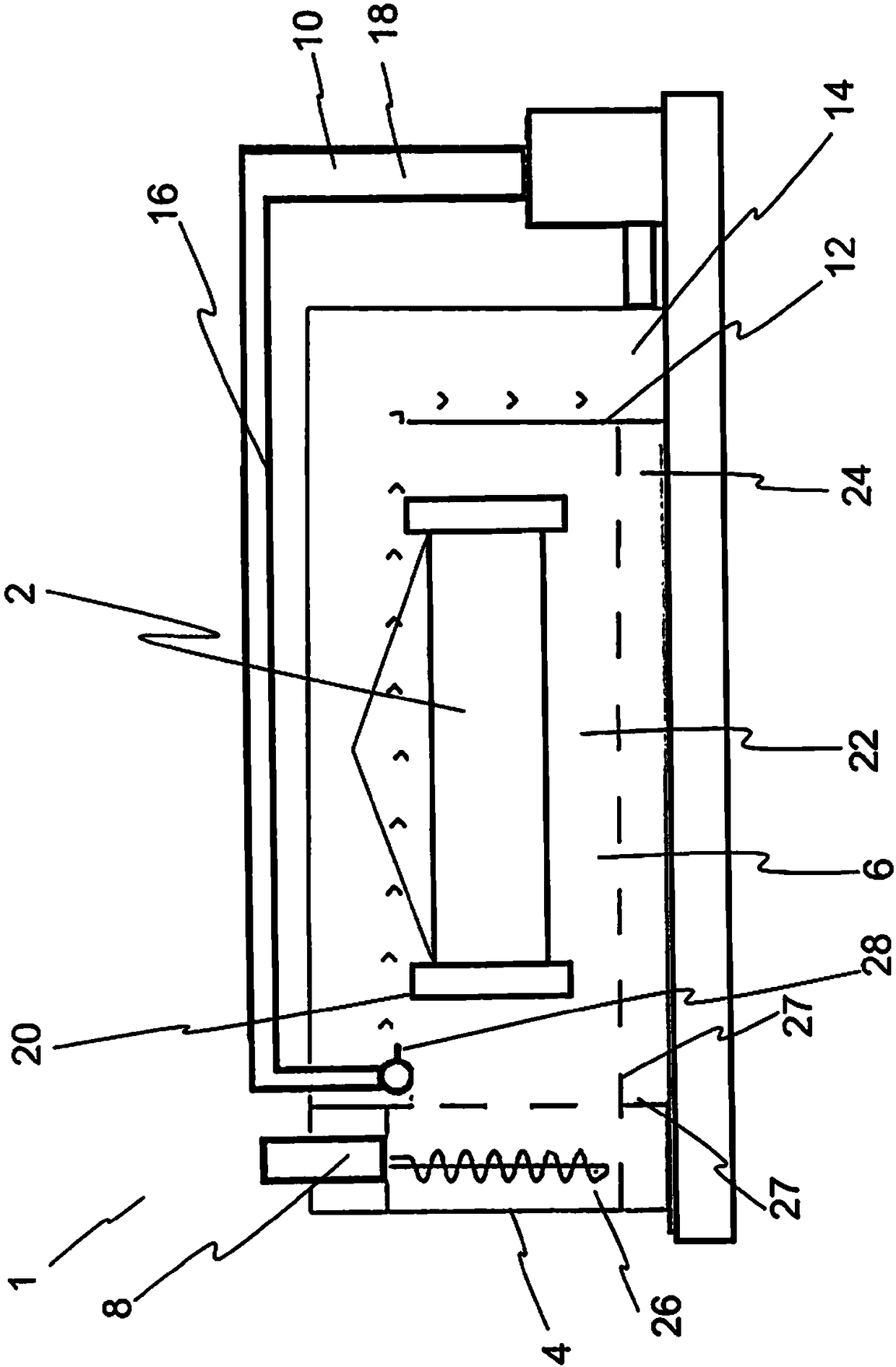

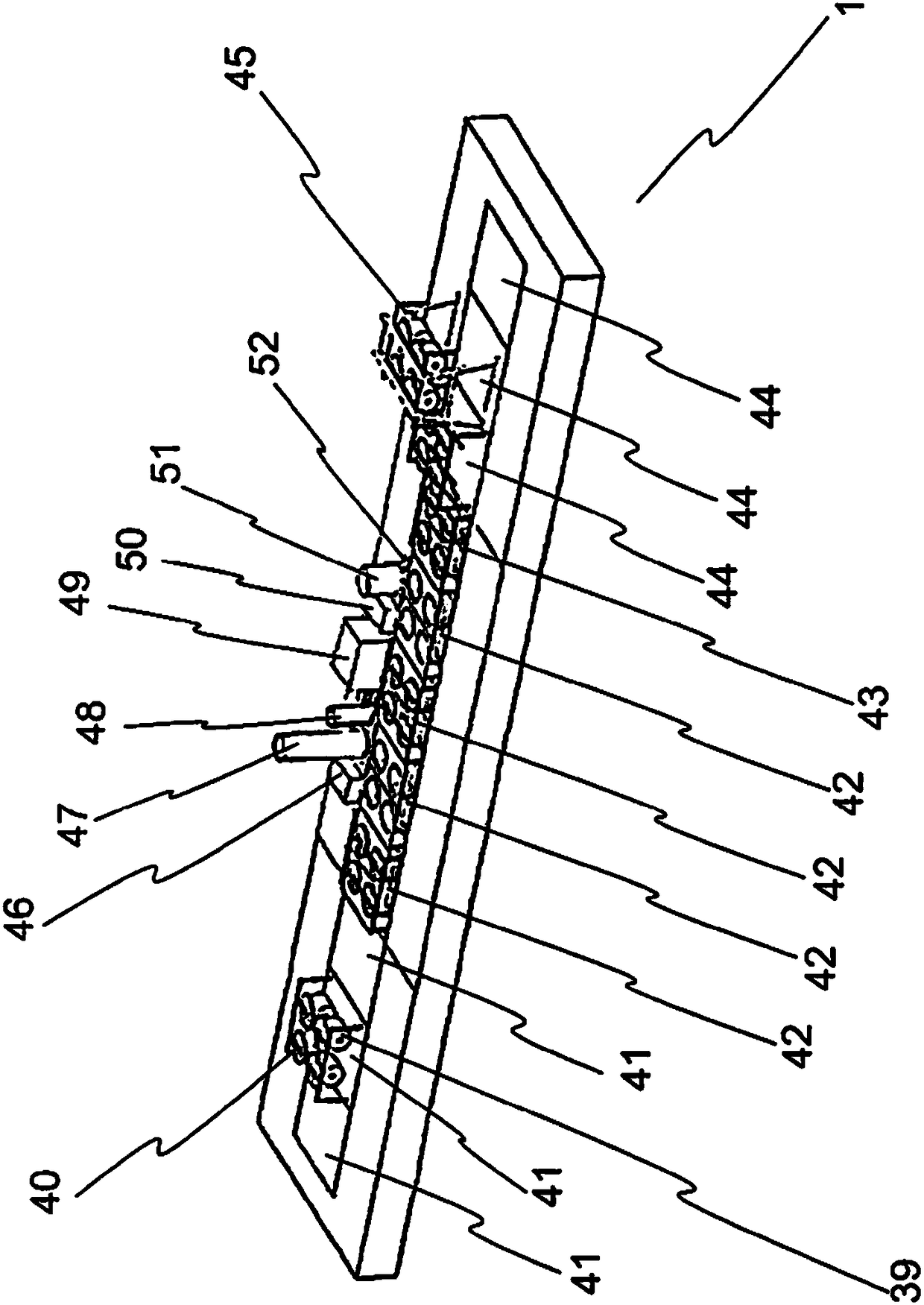

[0091] exist figure 1 A processing device 1 according to the invention is shown in . The treatment plant 1 is used for the treatment, in particular for degreasing, pickling, phosphating, descaling, preservation and descaling of one or more treatment objects 2 . The treatment objects 2 are preferably introduced into the treatment container 4 of the treatment plant 1 from above. The treatment container 4 is here preferably at least partially and particularly preferably completely filled with the treatment substance 6 . Furthermore, preferably, a temperature control device 8 is provided for temperature control, in particular for heat treatment of the substance 6 . Furthermore, preferably at least one pump device 10 is provided for circulating the treatment substance 6 and / or for establishing a dam-like flow 20 and / or for conveying back the treatment substance leaving the treatment container 4 into the processing container 4. The processing container 6 is separated from the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| ignition point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com