Experimental method of liquid flow characteristics in nanochannels

A liquid flow and nano-channel technology, applied in the field of experiments, can solve problems such as inability to accurately predict and measure, and achieve the effects of low cost, simple operation, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

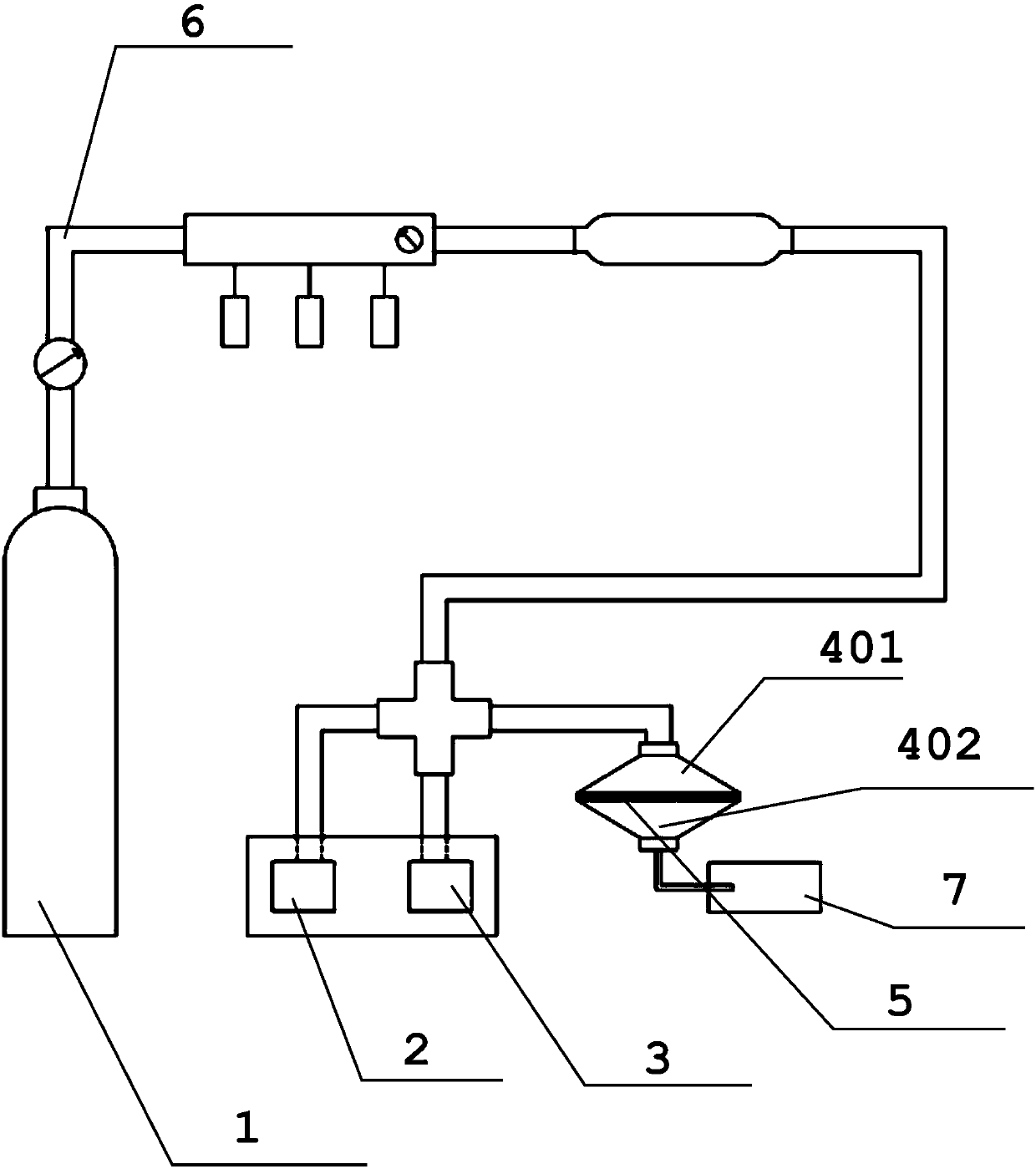

[0049] An experimental method of liquid flow characteristics in a nanochannel, the experimental method of liquid flow characteristics in the nanochannel comprises the following steps:

[0050] 1) select the aluminum oxide nano-membrane of 125 nanometer aperture, and measure its accurate diameter and pore density with scanning electron microscope;

[0051] 2) Add deionized water sterilized by ultraviolet light and filtered by a nanomembrane with a pore size of 25 nanometers into the liquid tank;

[0052] 3) Connect each pipeline and power supply with high-pressure plastic hose, and seal the interface with a hard seal;

[0053] 4) Clamp and seal the aluminum oxide nano-membrane with a pore size of 125nm through two sealing clips and sealing rubber rings using the upper and lower clamps containing the supporting sandstone;

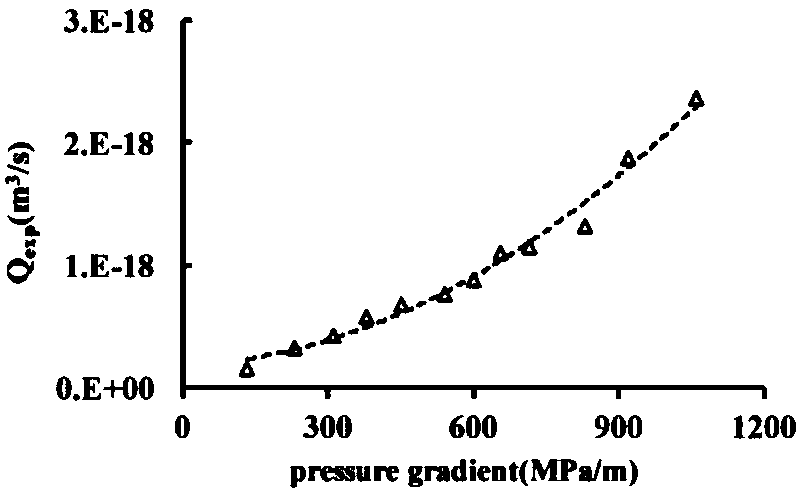

[0054] 5) Use high-purity nitrogen as a power source to pressurize and displace the entire experimental system, read the pressure and temperature through pres...

Embodiment 2

[0058] An experimental method of liquid flow characteristics in a nanochannel, the experimental method of liquid flow characteristics in the nanochannel comprises the following steps:

[0059] 1) Select an aluminum oxide nano-membrane with a pore size of 90 nanometers, and measure its accurate diameter and pore density with a scanning electron microscope;

[0060] 2) Add deionized water sterilized by ultraviolet light and filtered through a nanomembrane with a pore size of 25 nanometers into the liquid tank;

[0061] 3) Connect each pipeline and power supply with high-pressure plastic hose, and seal the interface with a hard seal;

[0062] 4) Clamp and seal the alumina nano-membrane with a pore size of 90nm by using the upper and lower clamps containing the supporting sandstone respectively through two sealing clamps and sealing rubber rings;

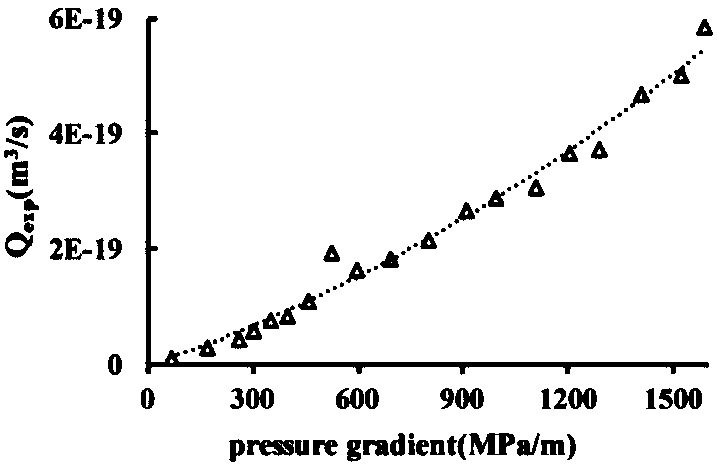

[0063] 5) Use high-purity nitrogen as a power source to pressurize and displace the entire experimental system, read the pressure and...

Embodiment 3

[0067] An experimental method of liquid flow characteristics in a nanochannel, the experimental method of liquid flow characteristics in the nanochannel comprises the following steps:

[0068] 1) Select an aluminum oxide nanofilm with a pore size of 65 nanometers, and measure its accurate diameter and pore density with a scanning electron microscope;

[0069] 2) Add deionized water sterilized by ultraviolet light and filtered by a nanomembrane with a pore size of 25 nanometers into the liquid tank;

[0070] 3) Connect each pipeline and power supply with high-pressure plastic hose, and seal the interface with a hard seal;

[0071] 4) Clamp and seal the aluminum oxide nano-membrane with a pore size of 65nm through two sealing clamps and sealing rubber rings using the upper and lower clamps containing the supporting sandstone;

[0072] 5) Use high-purity nitrogen as a power source to pressurize and displace the entire experimental system, read the pressure and temperature throug...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com