Microcosmic and nano-scale electro-mechanical coupling feature measurement device based on AFM and detection method thereof

A technology of measuring device and measuring method, which is applied in the measurement of the change force of the optical properties of the material when it is stressed, and the resistance of the material, which can solve the problems of difficult operation technology, impossible test, difficult operation, scientific research workers, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

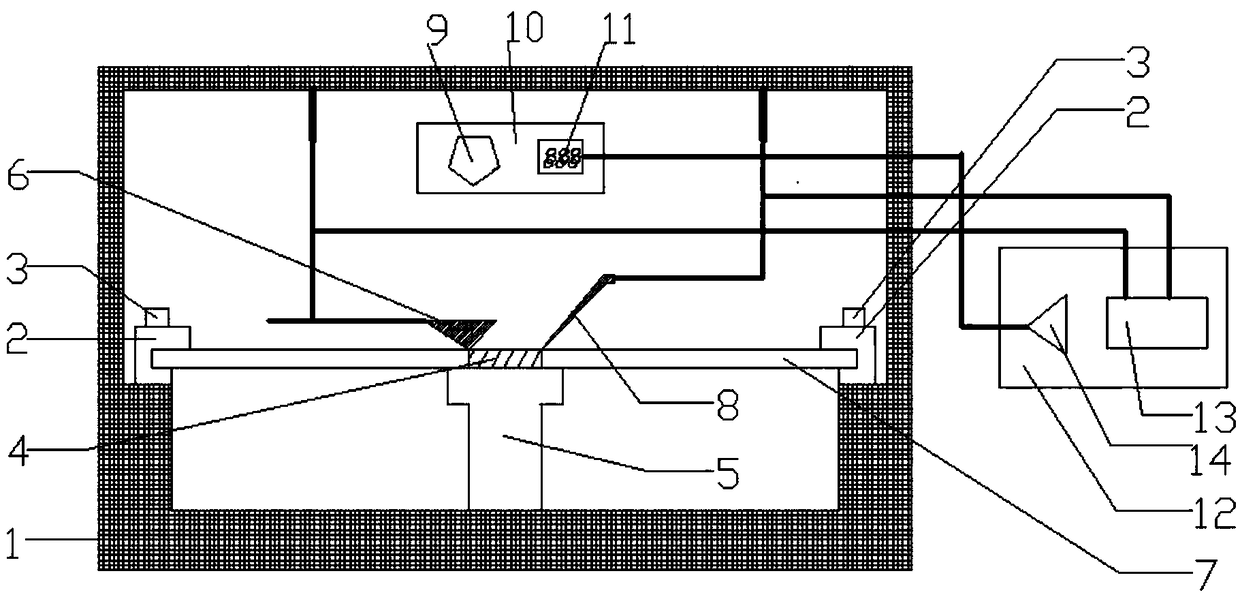

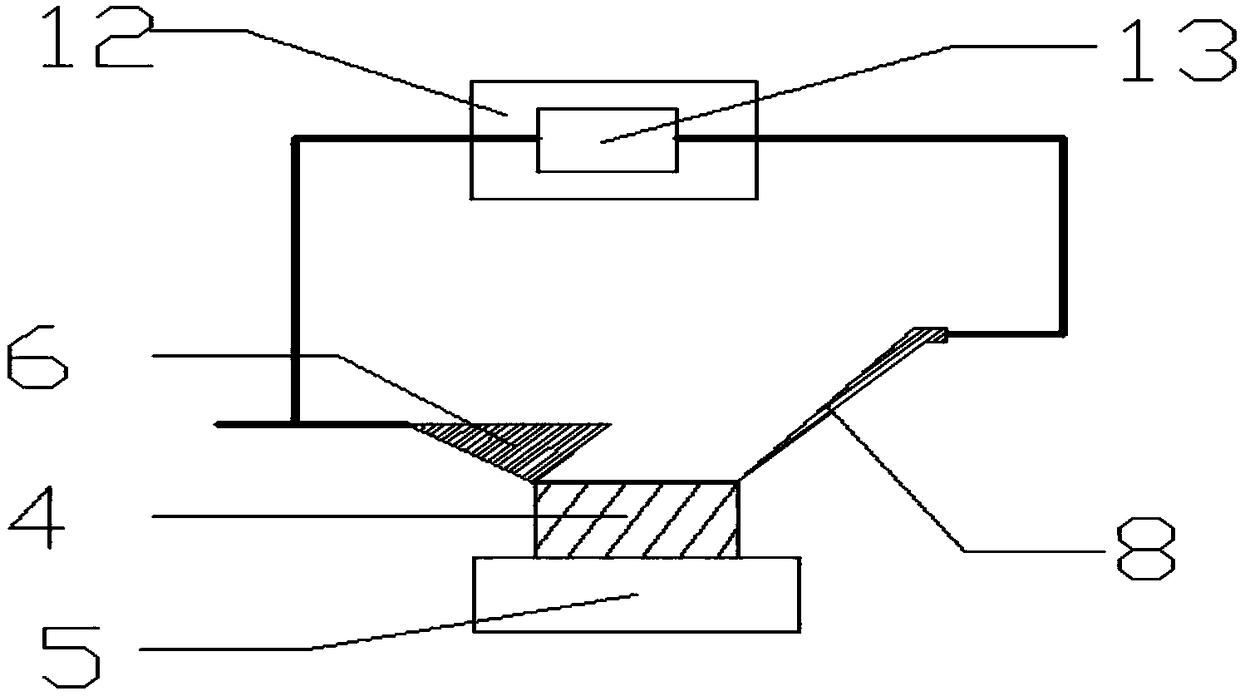

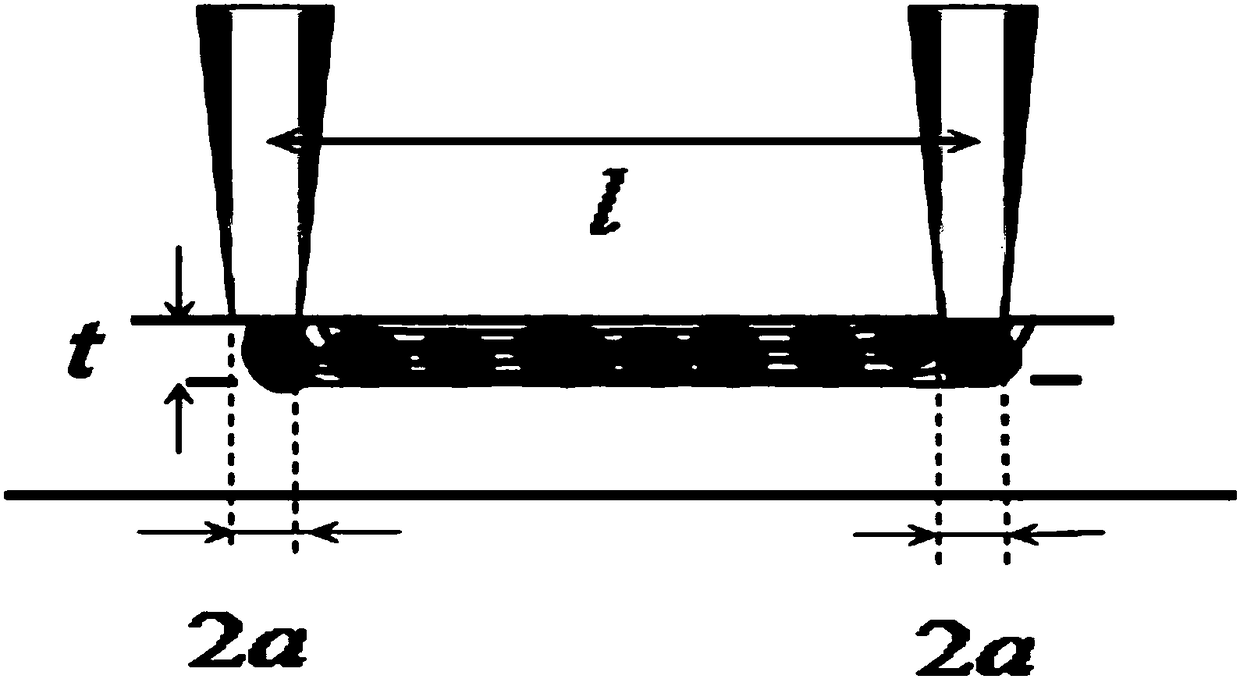

[0040] like figure 1 and figure 2As shown, the AFM-based micro / nano force-electric coupling characteristic measuring device of the present invention includes a piezoelectric driver 5, an AFM probe 6, a conductive second probe 8, a laser emitter 9, an AFM atomic force microscope 10, Detector 11 and data processing center 12; the two ends of the flexible elastic conductive sample 7 are installed on the fixed frame 1 through the clamp 2 and clamped with the nut 3; the movable piezoelectric driver 5 is installed on the fixed frame 1, and the The piezoelectric driver 5 is located on the bottom surface of the flexible elastic conductive sample 7; the AFM probe 6 and the second conductive probe 8 are installed on the fixed frame 1, and the AFM probe 6 is in contact with the su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com