An online measuring device and method for measuring the end face flange of a cage

A technology of measuring devices and cages, which is applied in the direction of measuring devices, mechanical measuring devices, and mechanical devices, etc., can solve the problems of reducing production efficiency, inability to realize online measurement, and unseen problems, so as to improve production efficiency and make online measurement fast convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to facilitate the understanding of the technical means, creative features and objectives achieved by the present invention, the present invention will be further described in conjunction with schematic diagrams, but the scope of protection claimed by the present invention is not limited to the scope described in the specific embodiments.

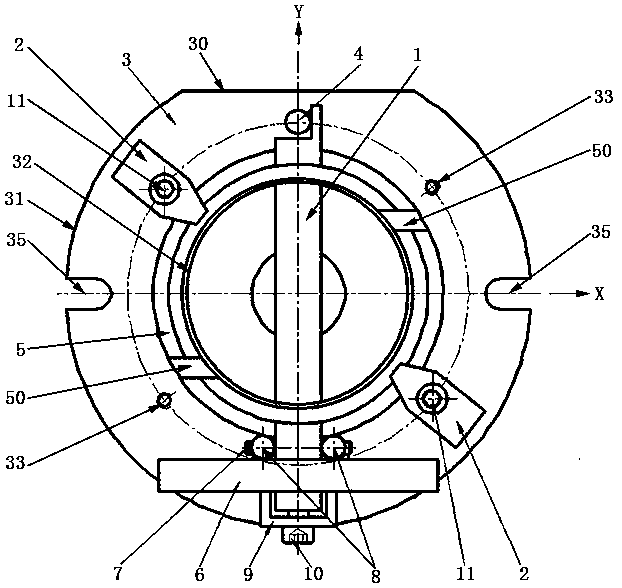

[0033] The structure of the cage is as figure 1 with figure 2 As shown, a number of window holes 51 are equally provided on the holder 5, preferably, the number of window holes 51 is 14 or 16; figure 1 As shown, one end of the holder 5 is provided with four flanges 50, of which two spaced apart flanges are arranged in parallel with the vertical center line of the holder 5, and the adjacent sides of the two flanges are the processing surface The distance between 500 and the vertical centerline of the cage 5 is H; the other two spaced flanges are arranged in parallel, and the adjacent sides of the two flanges are processed. The dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com