Online measuring device and measuring method for cage end flanges

A measuring device and cage technology, applied in the direction of measuring devices, mechanical measuring devices, mechanical devices, etc., can solve the problems of inability to realize online measurement, reduce production efficiency, and fail to see, so as to achieve fast and convenient online measurement and improve production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to facilitate the understanding of the technical means, creative features and goals achieved by the present invention, the present invention is further described below in conjunction with the schematic diagrams, but the scope of protection claimed by the present invention is not limited to the scope described in the specific implementation.

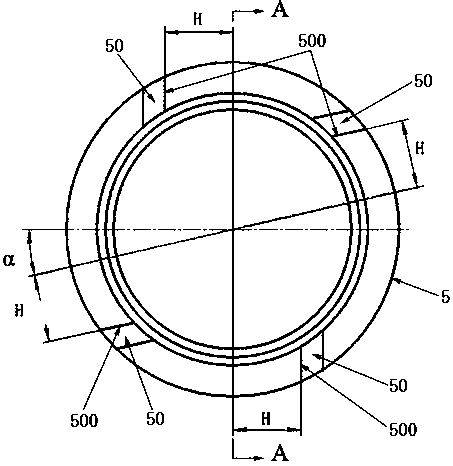

[0033] The structure of the cage is as figure 1 and figure 2 As shown, wherein, several windows 51 are evenly divided on the cage 5, preferably, the number of windows 51 is 14 or 16; as figure 1 As shown, one end of the cage 5 is provided with four flanges 50, wherein two flanges arranged at intervals are arranged parallel to the vertical center line of the cage 5, and the adjacently arranged side surfaces of the two flanges are the processing surfaces. The distance between the 500 and the vertical center line of the cage 5 is H; the other two spaced flanges are arranged in parallel, and the adjacent sides of the two fla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com