Nano particle for polymer turbidity standard substance and preparation method thereof

A standard substance and nanoparticle technology, applied in the direction of scattering characteristic measurement, transmittance measurement, etc., can solve problems such as poor stability, achieve good stability, improve stability, and slow particle settling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

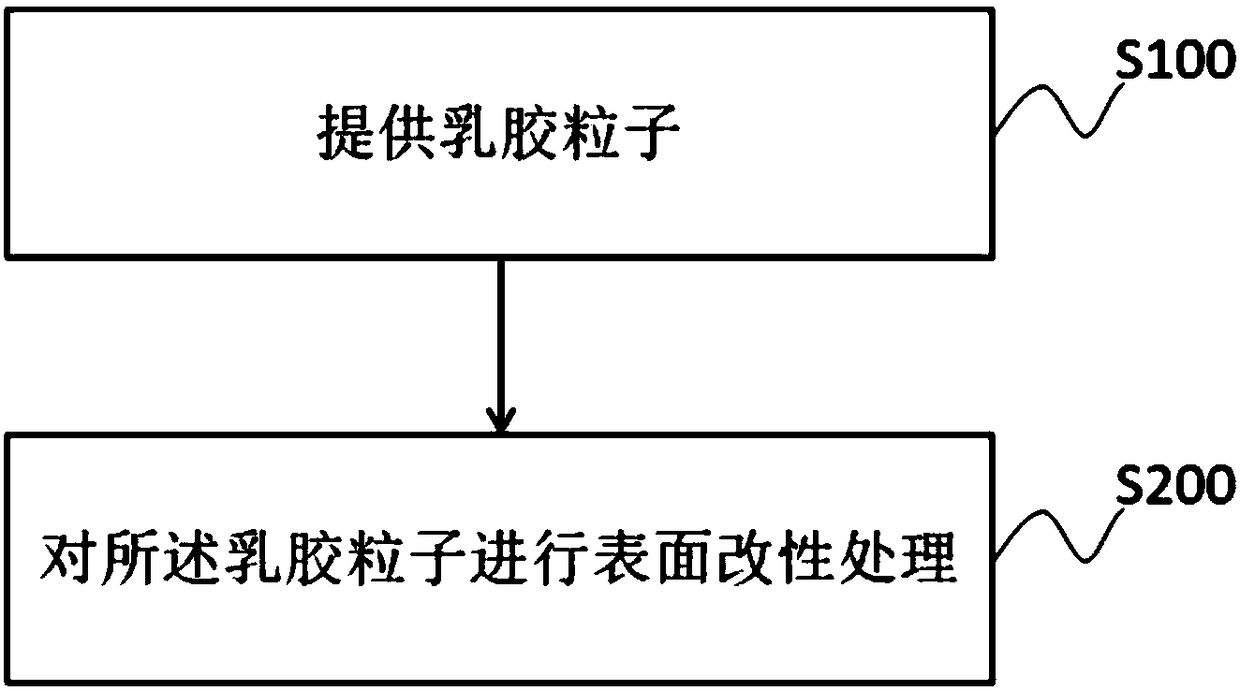

[0052] figure 1 It is a flow chart of the preparation method of nanoparticles for polymer turbidity standard substance according to the embodiment of the present invention. like figure 1 As shown, the method includes the following steps:

[0053] Step S100, providing latex particles.

[0054] Among them, the latex particles can be directly obtained by purchasing, or can be prepared by polymerization.

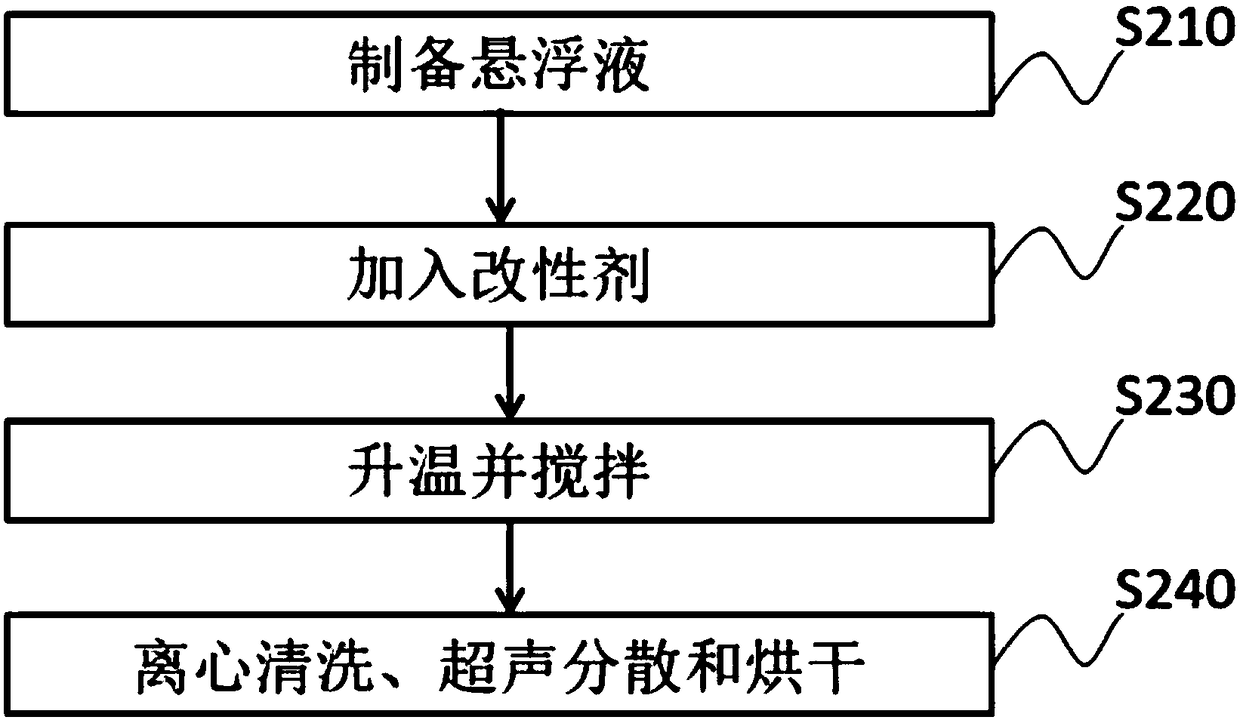

[0055] Step S200, performing surface modification treatment on the latex particles.

[0056] The purpose of the modification is to modify the surface of the latex particles with high-density negative or positive charges.

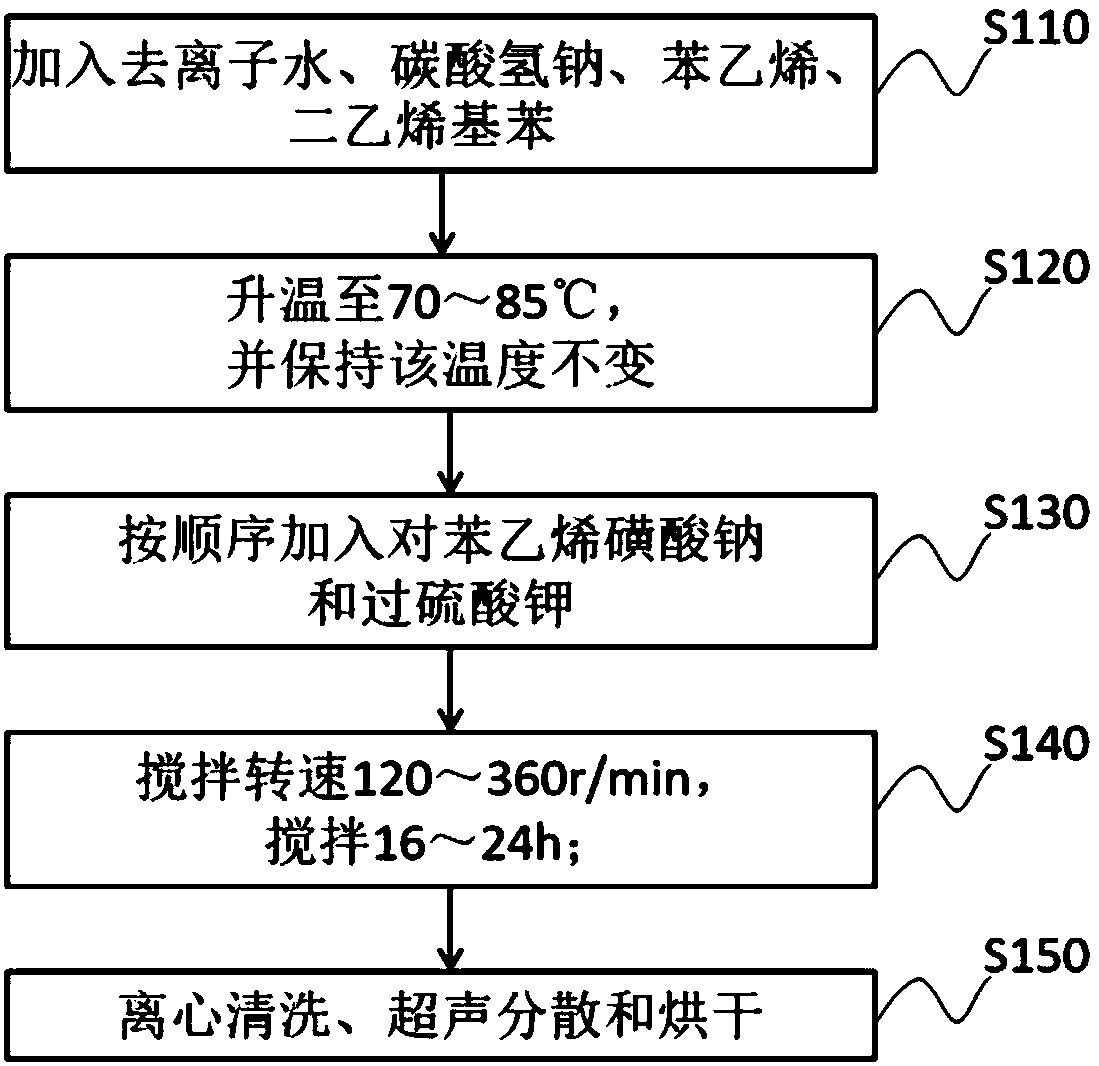

[0057] In step S100, the method for preparing the latex particles by polymerization comprises the following steps, such as figure 2 Shown:

[0058] Step S110, adding deionized water, sodium bicarbonate, styrene, and divinylbenzene into the reaction vessel.

[0059] Step S120, raising the temperature to 70-85°C, and keeping the temperature constant.

[0...

Embodiment 1

[0086] Embodiment 1, polymer turbidity standard substance is used nanoparticle (particle diameter 100nm)

[0087] A nano particle for a polymer turbidity standard substance is a monodisperse cross-linked polystyrene latex particle with a particle diameter of 100nm, the surface of the particle is modified with high-density positive charges, and the Zeta potential is 40mV-60mV.

[0088] The preparation method of the nanoparticles for the above-mentioned polymer turbidity standard substance comprises the following steps:

[0089] (1) Preparation of latex particles

[0090] 2500 mL of deionized water, 1.63 g of sodium bicarbonate, 180 g of styrene, and 27 g of divinylbenzene were added to the reaction vessel.

[0091] The temperature was raised to 75°C and maintained at this temperature.

[0092] 2.66 g of sodium p-styrene sulfonate and 0.81 g of potassium persulfate were sequentially added.

[0093] Adjust the stirring speed to 200r / min, and stir for 22h.

[0094] The latex p...

Embodiment 2

[0101] Embodiment 2, polymer turbidity standard substance is used nanoparticle (particle diameter 300nm)

[0102] A nanoparticle for a polymer turbidity standard substance is a monodisperse cross-linked polystyrene latex particle with a particle diameter of 300nm, the particle surface is modified with high-density negative charges, and the Zeta potential is -60mV to -40mV.

[0103] The preparation method of the nanoparticles for the above-mentioned polymer turbidity standard substance comprises the following steps:

[0104] (1) Preparation of latex particles

[0105] 1800 mL of deionized water, 1.22 g of sodium bicarbonate, 240 g of styrene, and 32 g of divinylbenzene were added to the reaction vessel.

[0106] The temperature was raised to 83°C and maintained at this temperature.

[0107] 0.77 g of sodium p-styrenesulfonate and 1.34 g of potassium persulfate were sequentially added.

[0108] Adjust the stirring speed to 150r / min, and stir for 16h.

[0109] The latex parti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com