Pneumatic adjustment cutter rod structure of underwater granulator

An underwater granulator and pneumatic adjustment technology, which is applied in metal processing and other directions, can solve the problems of unfavorable maintenance, particle tailings, and many debris, etc., and achieve the effects of facilitating disassembly and maintenance, improving the forming state, and increasing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further explained below in conjunction with the accompanying drawings.

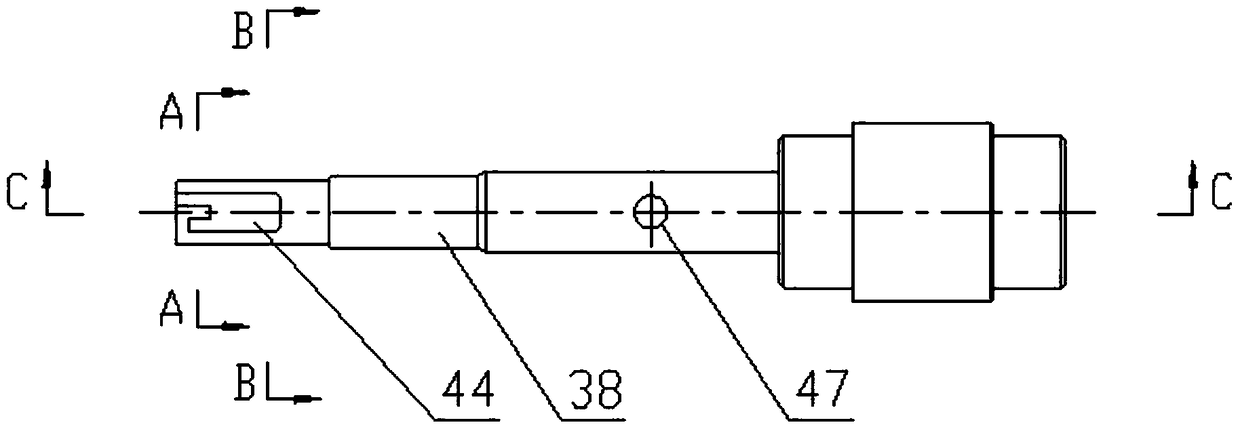

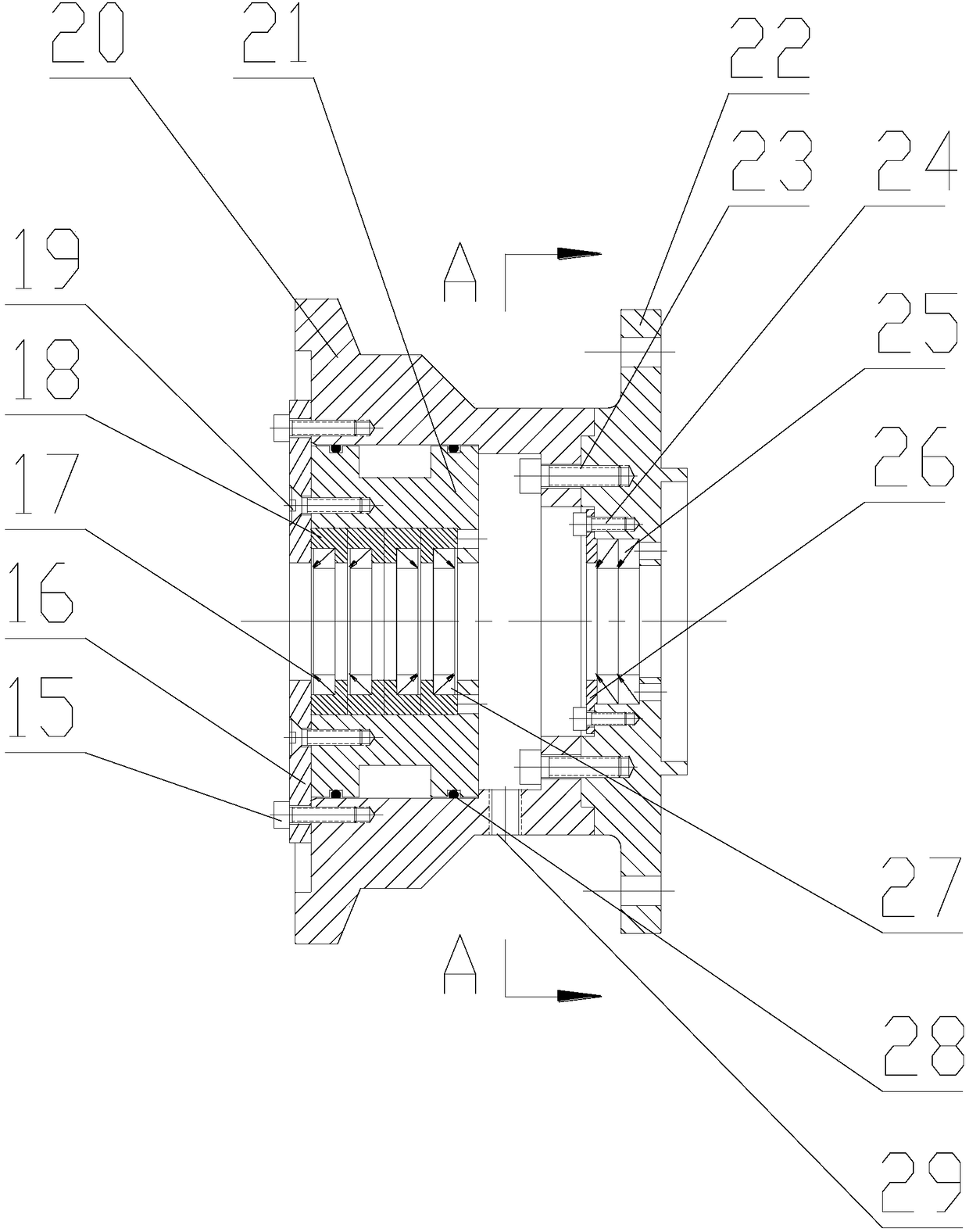

[0037] Such as Figures 1 to 13As shown, the structure of a pneumatically adjusted cutter bar of an underwater pelletizer of the present invention includes a cutter bar composition 5, a connecting flange 4 and a pneumatically adjusted structure. The knife rod composition 5 includes a knife rod 38, a bearing seat 39, a tapered roller bearing 41, a pneumatic plunger 36, a compression spring 35, a cutter seat 34, a cutter shaft 32, a cutter disk 31, and a cutter 30; The rear end of the seat 39 is connected with the AC motor, and the front end of the bearing seat 39 is connected with the rear end of the water cavity 2 of the underwater granulator through the connecting flange 4; the rear end of the cutter bar 38 is installed on the bearing seat 39 through the tapered roller bearing and connected with the output shaft 6 of the AC motor, the middle part of the cutter bar 38...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com