Efficient casting process for vertical grinding roller sleeve with simple model

A vertical mill roller sleeve and casting process technology, which is applied in the direction of manufacturing tools, casting molding equipment, casting molds, etc., can solve the problems that affect the authenticity rate of products, time-consuming and labor-consuming, and local looseness, so as to save production time and increase insurance. The effect of short coefficient and feeding distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

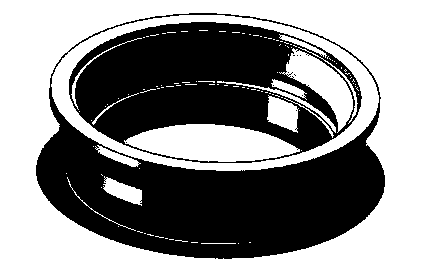

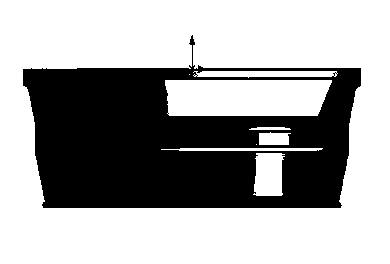

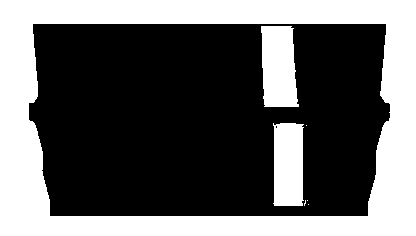

[0031] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, an efficient casting process of a simple vertical mill roller sleeve includes the following steps:

[0032] (1) The preparation of the casting process of the roller sleeve of the vertical mill, including the design of the gating system and the design of the riser, the design of the circular riser 2 at the upper center of the casting body 1 of the vertical mill roller sleeve 3 serves as a feeding channel function, the riser 2 is higher than the cone root position of the vertical mill roller sleeve casting body 1 to form a pressure head; (2), make a wooden mold according to the process requirements, and position the wooden mold on the template; (3), Make casting mold; (4), close case, dry sand mold, the molding sand used is made of the following raw materials by weight: 100 parts of silica sand, 12 parts of water glass, 15 parts of water, 0.8 part of phenolic resin, 25 parts of bentonite and ...

Embodiment 2

[0035] The molding sand used in step (4) is made of the following raw materials in parts by weight: 100 parts of silica sand, 10 parts of water glass, 10 parts of water, 0.5 parts of phenolic resin, 20 parts of bentonite and 5 parts of aluminum tripolyphosphate; the rest are the same as in the implementation example 1.

Embodiment 3

[0037] The molding sand used in step (4) is made from the following raw materials in parts by weight:

[0038] 100 parts of silica sand, 15 parts of water glass, 20 parts of water, 1 part of phenolic resin, 30 parts of bentonite and 10 parts of aluminum tripolyphosphate; the rest are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com