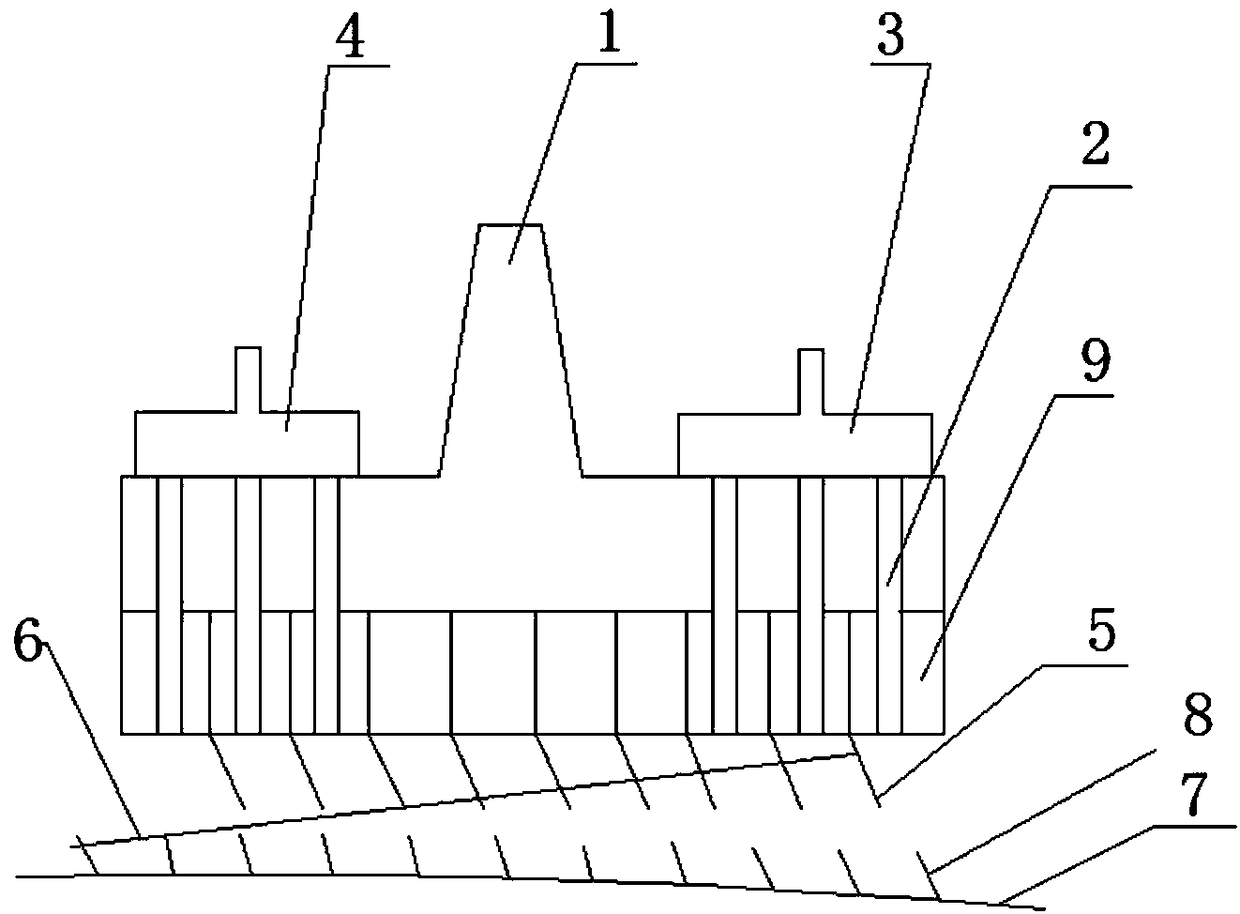

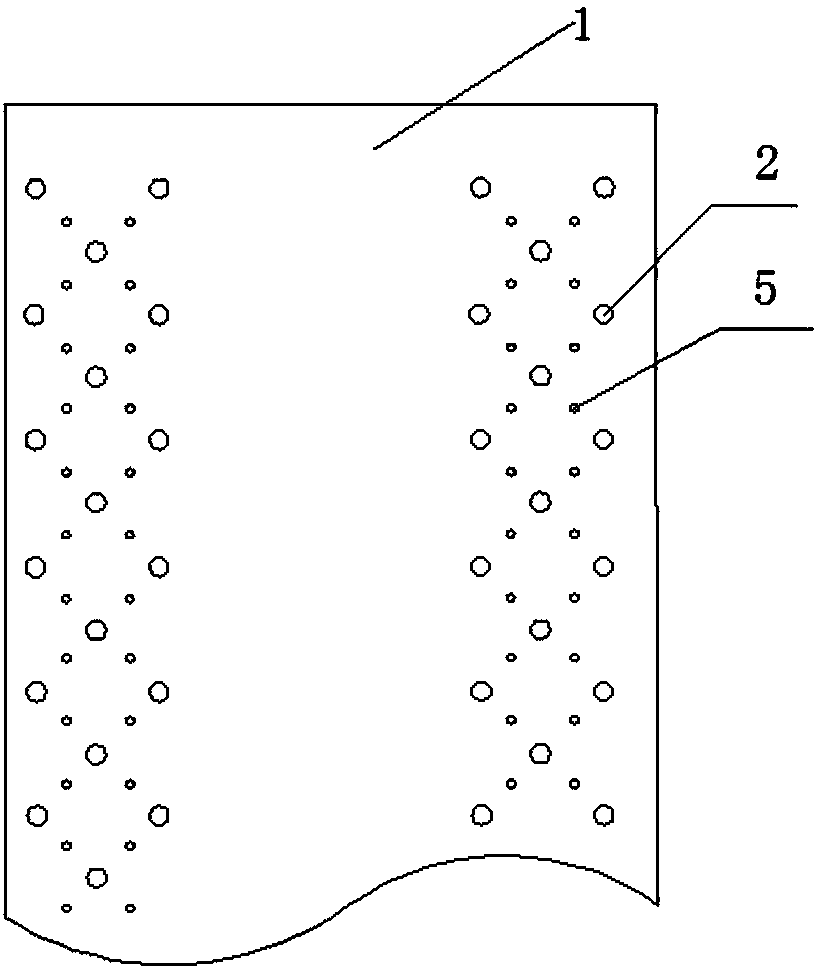

Carding machine cover plate, carding machine and method for flexible carding spinning

A carding machine and cover plate technology, which is applied in the field of textile processing, can solve the problems of fiber carding that cannot be effectively strengthened for fiber holding, and achieve the effects of improving free carding efficiency, increasing strength, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Use the sample of cotton fiber raw material produced in China (features: cotton is medium fiber, relatively clean), pass through the existing carding machine (purchased from Qufu Huifu Machinery Co., Ltd.) and the carding machine of the present invention respectively through the existing carding machine on the market, adopt the same mechanical The parameters are sorted out, and the results are shown in the table below:

[0049] Chinese cotton fiber

[0050] The above results show that under the same conditions, the carding machine provided by the present invention can increase the productivity of fiber strips, reduce the productivity of flat flowers, significantly improve the utilization rate of cotton fiber raw materials, thereby greatly saving production costs.

Embodiment 2

[0052] Use Chinese-made wool fiber raw material samples (features: short fibers, with certain turns or curls), pass through the existing carding machine (purchased from Qufu Huifu Machinery Co., Ltd.) and the carding machine of the present invention respectively on the market, using the same The mechanical parameters are sorted out, and the results are shown in the table below:

[0053] Wool fiber from China

[0054] The above results show that under the same conditions, the carding machine provided by the present invention can increase the productivity of fiber strips, reduce the productivity of flat flowers, significantly improve the utilization rate of cotton fiber raw materials, thereby greatly saving production costs.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com