Multi-layer wire-splitting knife device

A knife device and filament separation technology, used in filament/thread forming, textile and papermaking, fiber processing, etc., can solve problems such as increased energy consumption, increased material loss, unfavorable equipment storage, etc., to reduce floor space, reduce The effect of layout difficulty and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

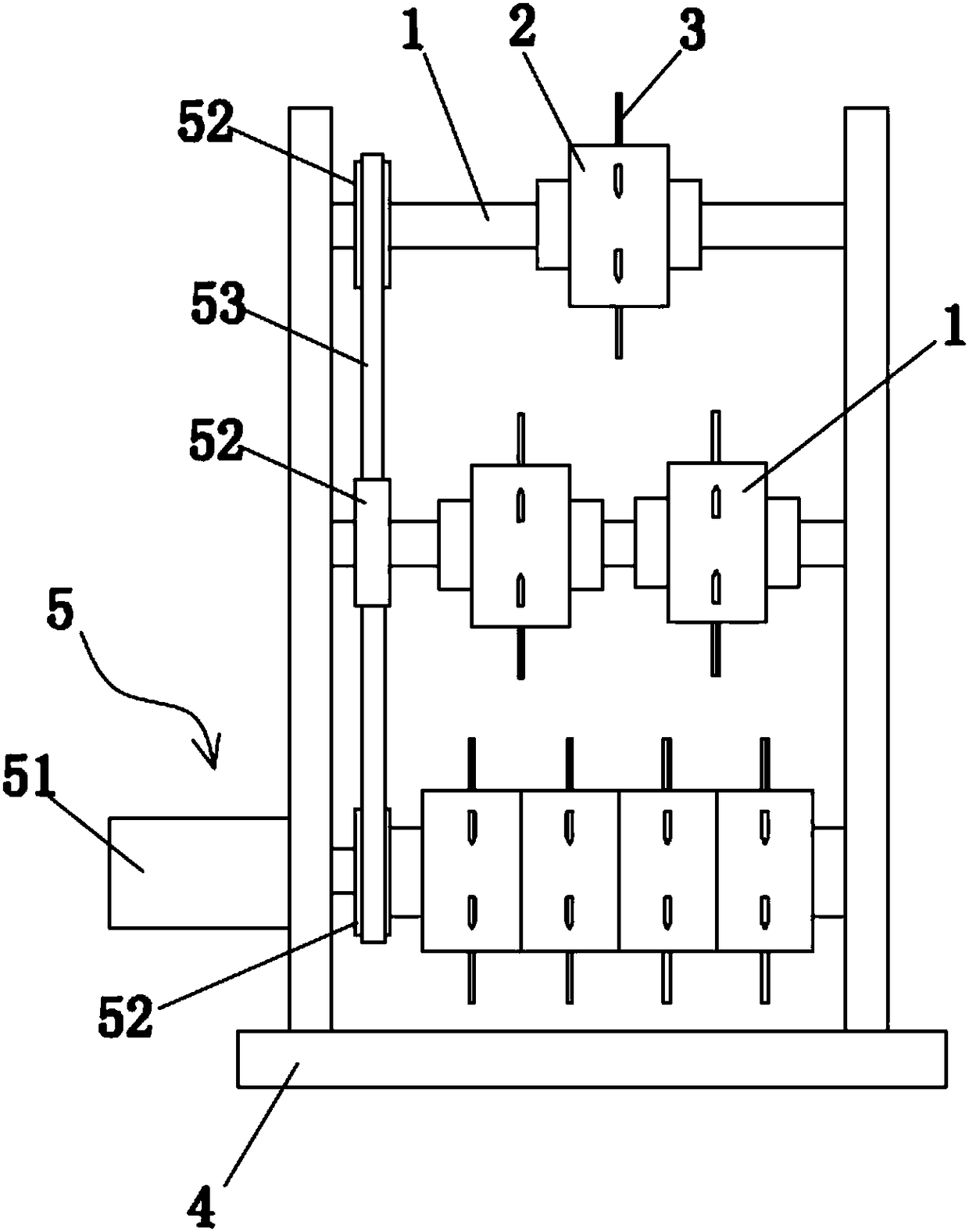

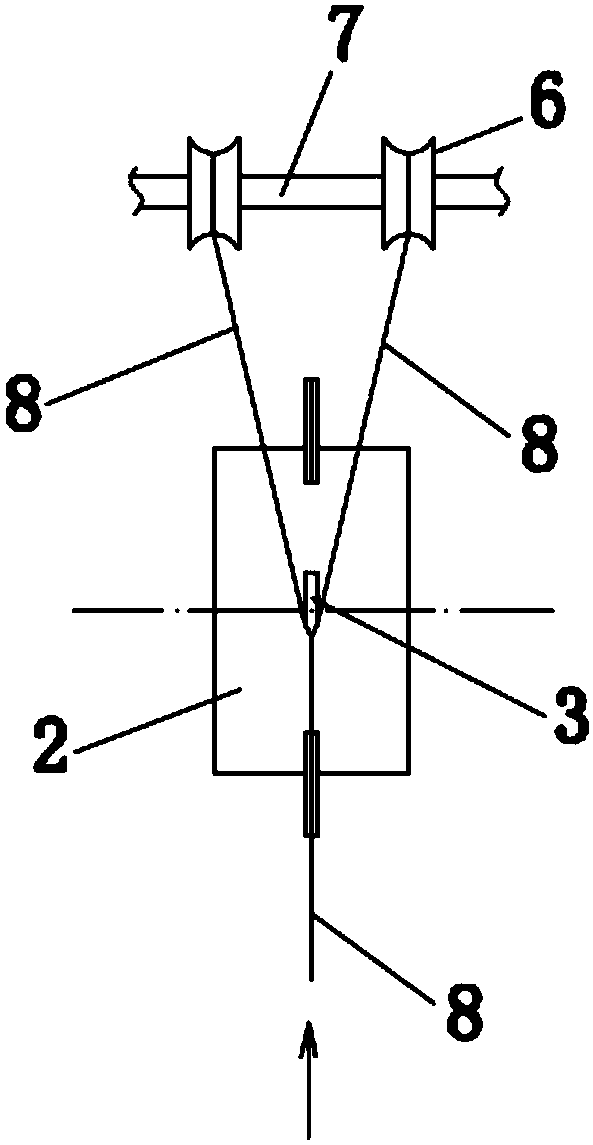

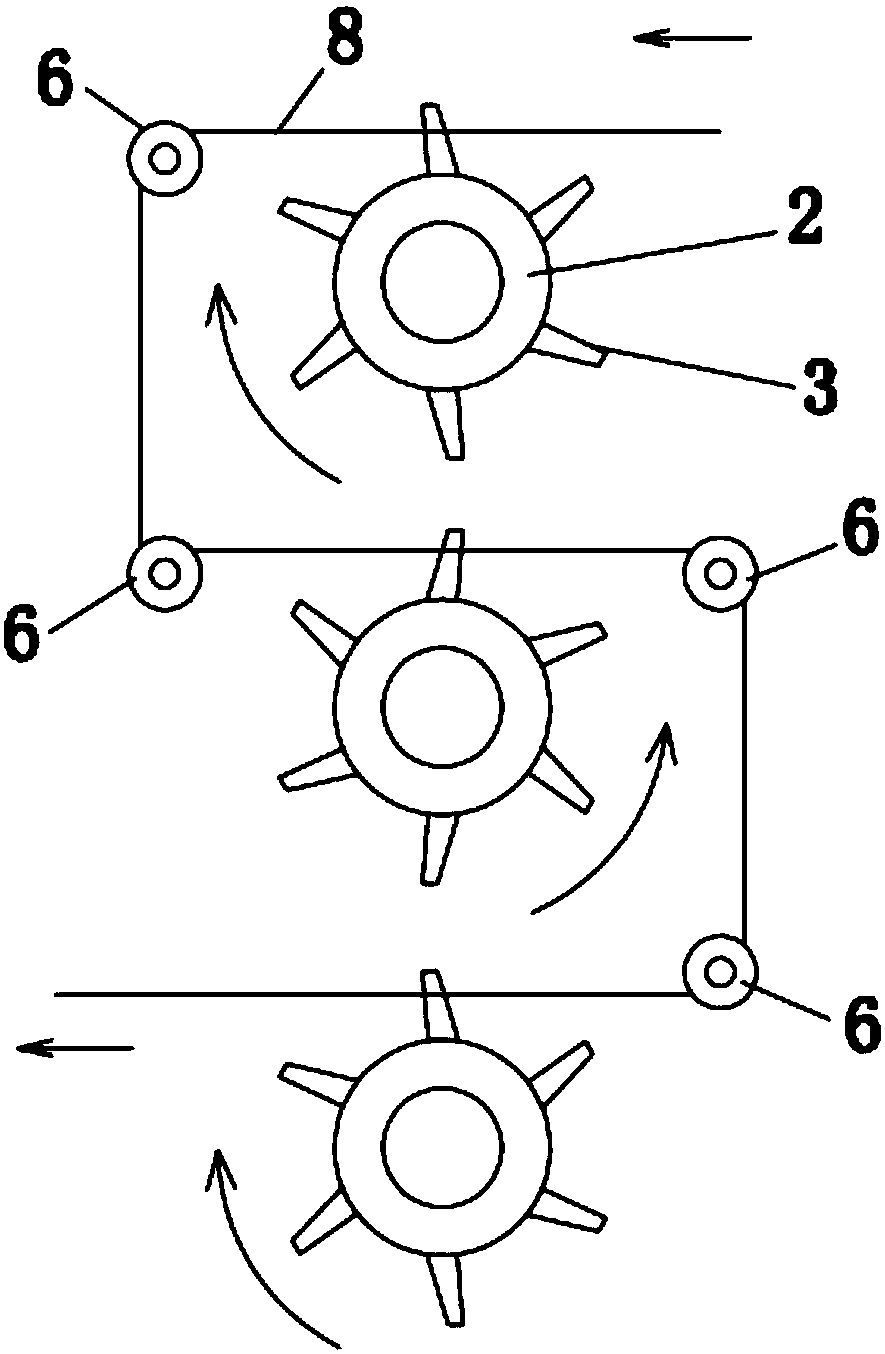

[0027] The specific embodiment of the present invention is as Figure 1 to Figure 4 As shown, a multi-layer wire splitter device includes a horizontally extending rotating shaft 1, and also includes a base 4 for installing the rotating shaft 1. The number of rotating shafts 1 is at least two and arranged sequentially from top to bottom, each Each rotating shaft 1 is equipped with a tool holder 2 that rotates with it, and a plurality of blades 3 are evenly distributed around the rotation axis of the tool holder 2; on two adjacent rotating shafts 1, the tool holder on the lower rotating shaft 1 2. The number is twice the number of knife rests 2 on the upper rotating shaft 1. The base 4 is provided with a plurality of reversing wheels 6 for guiding the divided plastic film to the next knife rest 2. The seat 4 is provided with a driving mechanism 5 that can rotate the tool holders 2 on two adjacent rotating shafts 1 in opposite directions.

[0028] The driving mechanism 5 include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com