Polypyrrole coated low-carbon alkane cold storage material and preparation method thereof

A technology for low-carbon alkanes and cold storage materials, which is applied in heat exchange materials, chemical instruments and methods, etc., can solve the problems of not making fundamental breakthroughs, and achieve the effects of convenient preparation process, convenient packaging and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) The aqueous solution of sodium carboxymethyl cellulose with a mass fraction of 1%, the aqueous solution of sodium polyacrylate with a mass fraction of 1%, and the aqueous solution of polyvinyl alcohol with a mass fraction of 1% are 20:20:1 by volume, at room temperature Stir and mix evenly to obtain A solution;

[0024] (2) Slowly add low-carbon alkanes dropwise to solution A, and stir at room temperature for 1 hour to obtain solution B. Described low-carbon alkane is n-tridecane; The volume ratio of described n-tridecane and A solution is 1:2;

[0025] (3) Add a certain amount of diatomaceous earth to the mixed solution of thioglycolic acid and ethanol, stir at 60°C for 8 hours, filter, wash with industrial alcohol, and dry spontaneously at room temperature to obtain powder C. The mass fraction of thioglycolic acid in the mixed solution of thioglycolic acid and ethanol is 2%; the mass ratio of the mixed solution of thioglycolic acid and ethanol to diatomaceous ear...

Embodiment 2

[0031] (1) The aqueous solution of sodium carboxymethyl cellulose that is 2% by mass fraction, the aqueous solution of sodium polyacrylate and the aqueous solution of polyvinyl alcohol that are 2% by mass fraction are 20:20:1 by volume, room temperature Stir and mix evenly to obtain A solution;

[0032] (2) Slowly add low-carbon alkanes dropwise to solution A, and stir at room temperature for 1 hour to obtain solution B. Described lower carbon alkane is n-tetradecane; The volume ratio of described n-tetradecane and A solution is 1:2;

[0033] (3) Add a certain amount of diatomaceous earth to the mixed solution of thioglycolic acid and ethanol, stir at 60°C for 8 hours, filter, wash with industrial alcohol, and dry spontaneously at room temperature to obtain powder C. The mass fraction of thioglycolic acid in the mixed solution of thioglycolic acid and ethanol is 2%; the mass ratio of the mixed solution of thioglycolic acid and ethanol to diatomaceous earth is 20:1.

[0034] ...

Embodiment 3

[0039] (1) The aqueous solution of sodium carboxymethyl cellulose with a mass fraction of 1.5%, the aqueous solution of sodium polyacrylate with a mass fraction of 1.8%, and the aqueous solution of polyvinyl alcohol with a mass fraction of 1.5%, in a volume ratio of 20:20:1, at room temperature Stir and mix evenly to obtain A solution;

[0040] (2) Slowly add low-carbon alkanes dropwise to solution A, and stir at room temperature for 1 hour to obtain solution B. Described low-carbon alkane is the mixture (mass ratio is 1:1) that is n-tridecane and n-tetradecane; The volume ratio of described low-carbon alkane and A solution is 1:2;

[0041] (3) Add a certain amount of diatomaceous earth to the mixed solution of thioglycolic acid and ethanol, stir at 60°C for 8 hours, filter, wash with industrial alcohol, and dry spontaneously at room temperature to obtain powder C. The mass fraction of thioglycolic acid in the mixed solution of thioglycolic acid and ethanol is 2%; the mass ra...

PUM

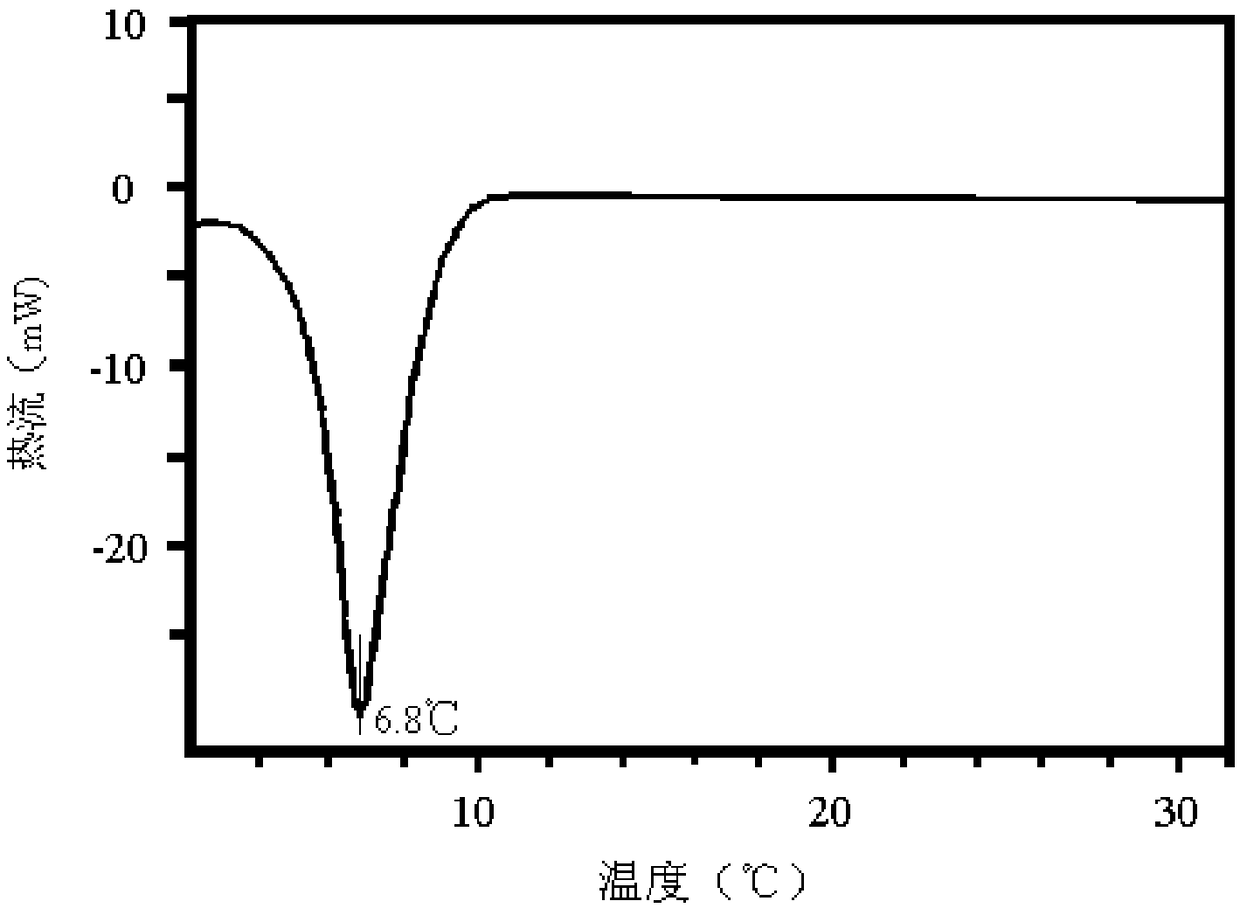

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com