Cellulose solution and preparation method thereof

A cellulose solution and cellulose technology, applied in the field of cellulose, can solve the problems of increasing the difficulty of cellulose processing, difficult to destroy the hydrogen bond network, and difficult to dissolve cellulose

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The invention provides a kind of preparation method of cellulose solution, comprises the steps:

[0027] (1) Under the condition of 15-30°C, soak the cellulose raw material in water, and then dry to obtain swollen cellulose;

[0028] (2) mixing the cellulose obtained in the step (1) with a polar organic solvent to obtain a cellulose dispersion;

[0029] (3) The cellulose dispersion obtained in the step (2) is mixed with a tetraalkyl quaternary ammonium base at 15~30° C.

[0030] Mixing under conditions to obtain a cellulose solution, the mixing is carried out under stirring, the stirring speed is 200-400r / min, and the stirring time is 2-6h.

[0031] In the present invention, unless otherwise specified, the reagents for preparing the cellulose solution are commercially available products well known to those skilled in the art.

[0032] The invention soaks the cellulose raw material in water under the condition of 15-30 DEG C, and then dries to obtain the swollen cellul...

Embodiment 1

[0047] TBAH pretreatment: Weigh 20 g of commercially available TBAH products, and treat in a rotary evaporator with a vacuum degree of -0.098 kPa at 60° C. for 60 min to remove moisture to obtain anhydrous TBAH. The DMSO was treated by vacuum distillation to obtain dehydrated DMSO.

[0048] Weigh 5.0 g of broad-leaved wood cellulose with a balance, soak it in 200 mL of water for 14 hours at 20 ° C, filter, and dry the filtered broad-leaved wood cellulose in a drying oven at 105 ° C for 24 hours to obtain a swollen broad-leaved wood cellulose;

[0049] Disperse 20 mg of swollen broad-leaved wood cellulose in 1224.72 mg DMSO, then add 306.18 mg of TBAH, and stir magnetically at 20°C for 2 hours at a speed of 300 r / min to obtain a broad-leaved wood with a mass concentration of 1.29 wt.%. Cellulose solution.

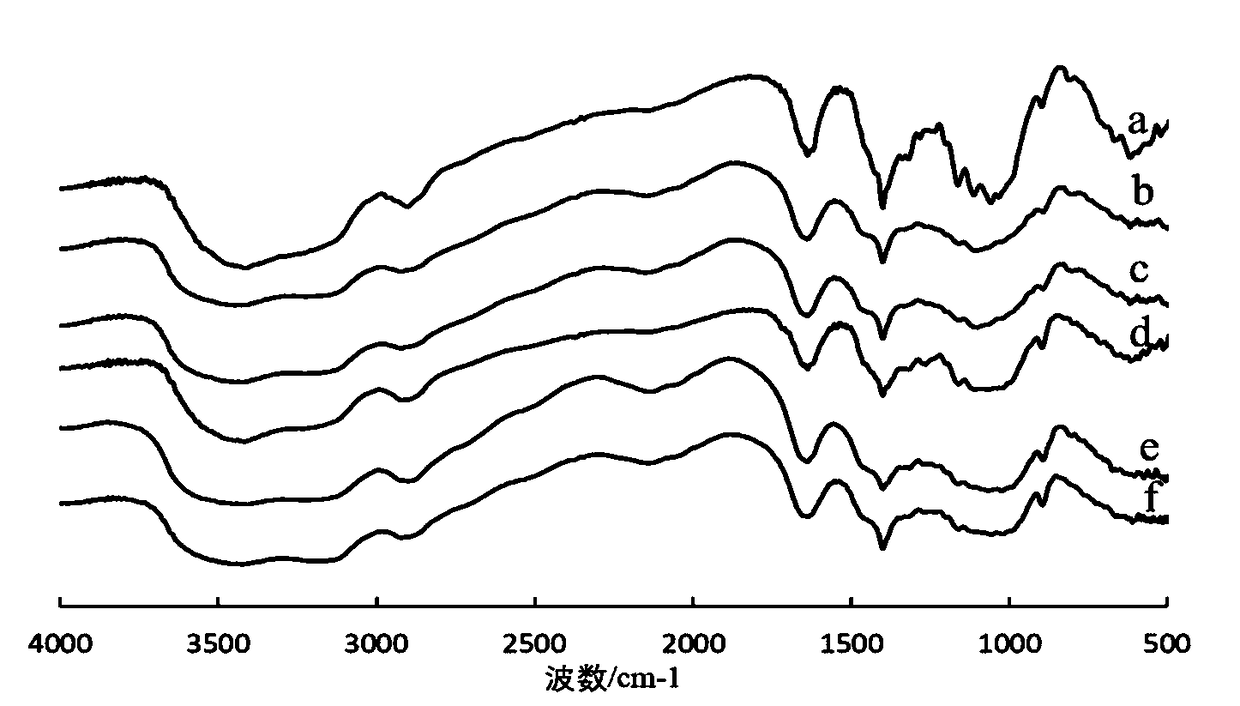

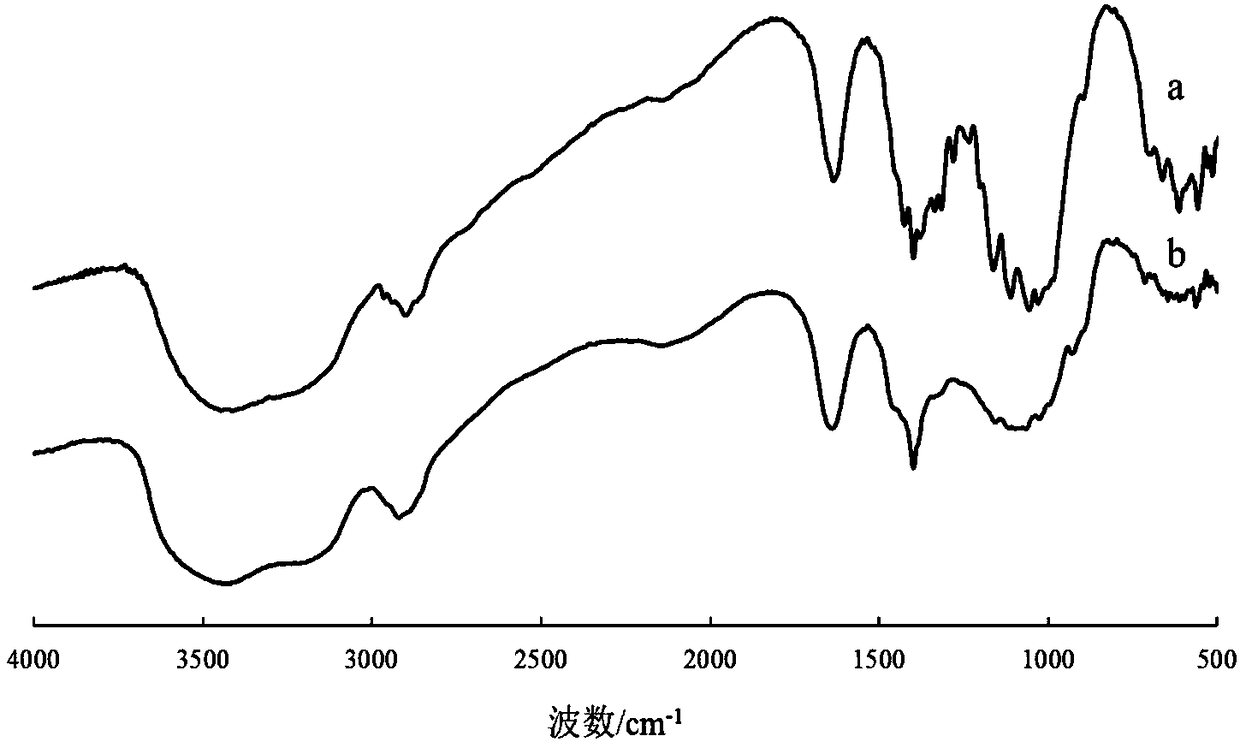

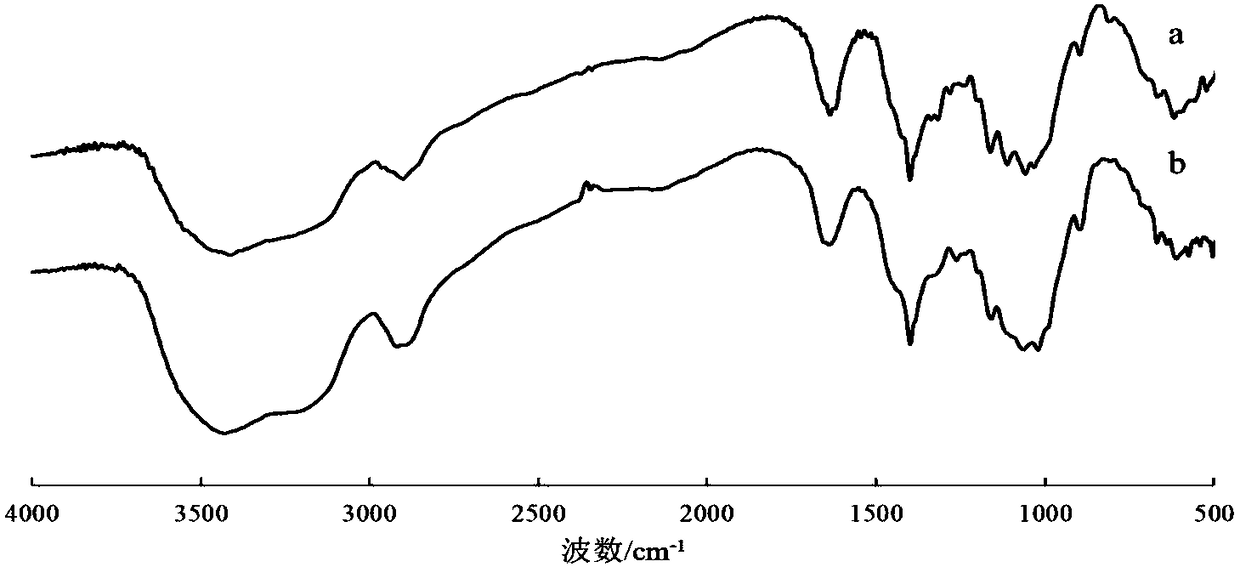

[0050] Adopt Fourier Transform Infrared Spectrometer (FT-IR Spectrometer) to analyze the broad-leaved wood cellulose raw material and the broad-leaved wood cellulose solut...

Embodiment 2

[0054] The broad-leaved wood cellulose solution was prepared according to the method of Example 1, the difference being that the soaking temperature was 25° C., and the soaking time was 20 h; the mass of the swollen broad-leaved cellulose was 50 mg, and the stirring time for mixing was 6 h, and the obtained The mass concentration of the hardwood cellulose solution is 3.2wt.%.

[0055] According to the method of embodiment 1, the cellulose molecular structure in the obtained broad-leaved wood cellulose solution is characterized, as figure 1 shown. figure 1 Among them, c is the FT-IR curve of the hardwood cellulose solution obtained in this example. Comparing a and c, it can be seen that the molecular structure of the cellulose in the hardwood cellulose solution obtained in this embodiment remains basically unchanged compared with the hardwood cellulose raw material, which shows that the broadleaf cellulose is in the fiber described in the present invention. It is directly dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com