A kind of coke oven ceramic hot wiping supplementary material and preparation method thereof

A technology of ceramics and filling material, which is applied in the field of ceramic patching material for hot repair of coke ovens and its preparation. It can solve the problems of insufficient combustion of materials, affecting normal production of coke ovens, and low welding repair efficiency, so as to meet continuous Production operations, faster overall stability, faster patching effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

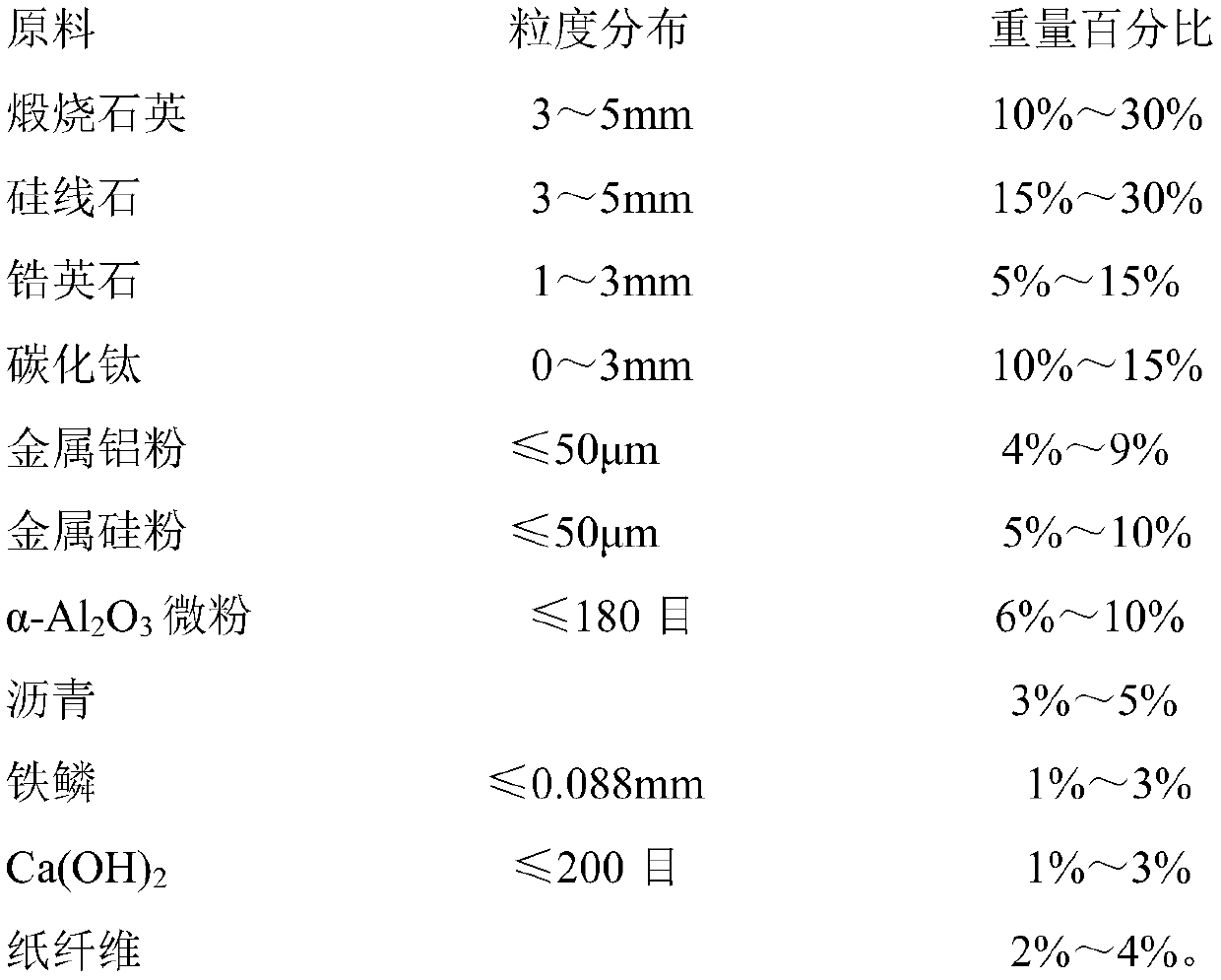

[0034] A kind of coke oven ceramics hot-wiping supplementary material, its raw material formula is shown in Table 1:

[0035] Weigh various materials according to the proportions stated in Table 1, put the materials except asphalt into the mixer and mix for 5-6 minutes, then add the liquid asphalt heated to above 70°C to the above mixed materials and continue to mix and stir for 2 ~3 minutes. After mixing, apply the material on the wall to be repaired, and spread evenly and smoothly. Then spray the surface of the material with oxygen to help it burn. During the blowing process, the oxygen flow rate is from small to large, and it is enough to blow for 3 to 5 minutes. Patching done.

[0036] Its main physical and chemical indicators are as follows:

[0037]

Embodiment 2

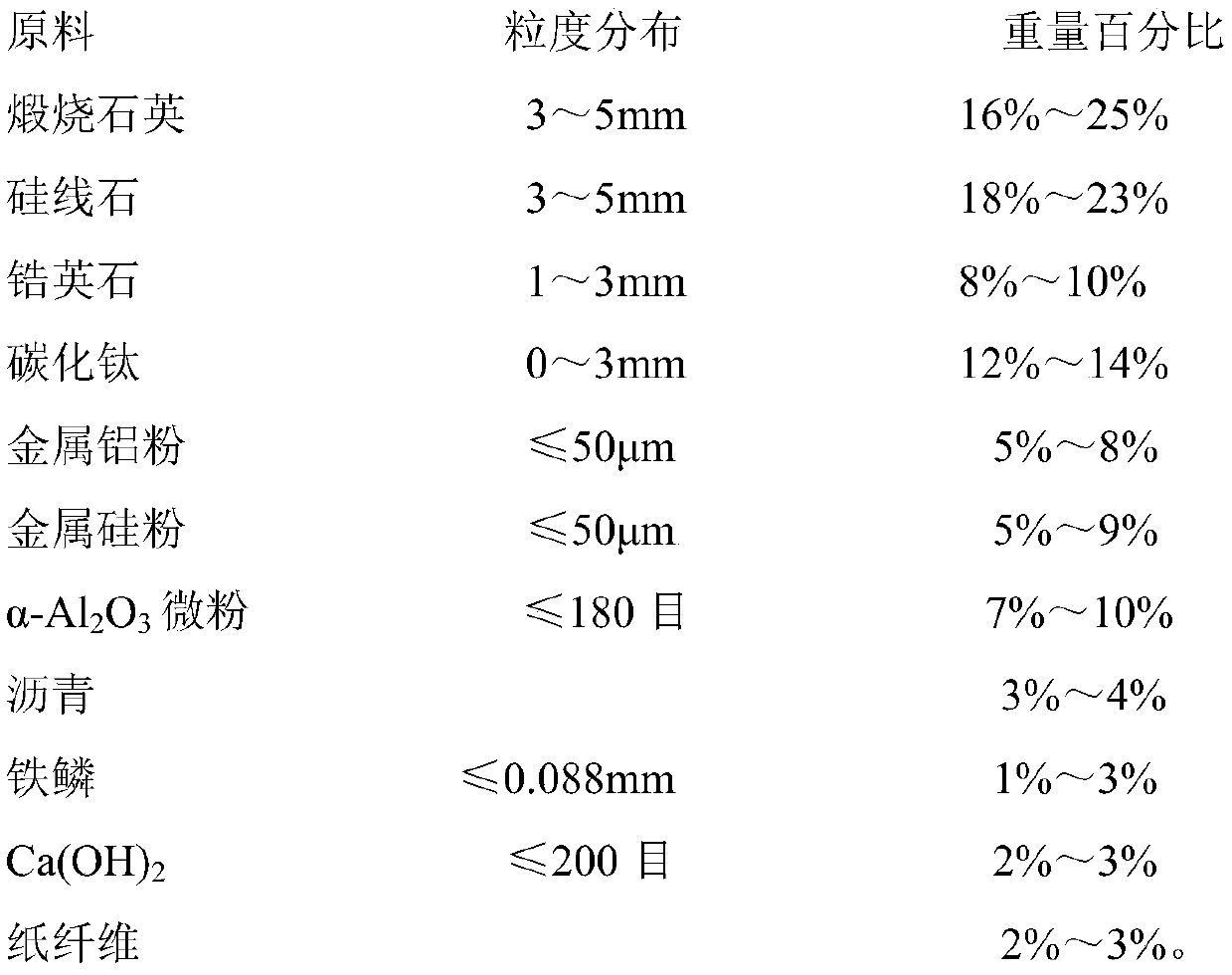

[0039] A kind of coke oven ceramics hot-wiping supplementary material, its raw material formula is shown in Table 1:

[0040] The preparation of coke oven ceramic hot-wiping supplement and the method of using the supplement to repair the coke oven are the same as in Example 1, and its main physical and chemical indicators are as follows:

[0041]

Embodiment 3

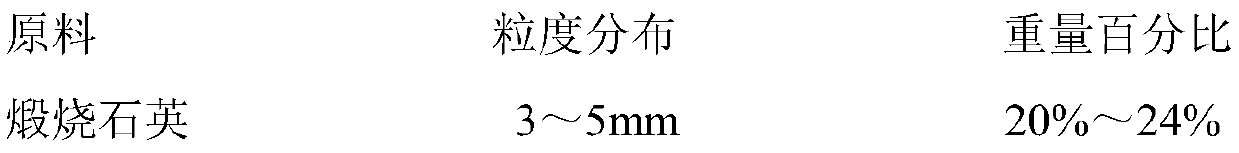

[0043] A kind of coke oven ceramics hot-wiping supplementary material, its raw material formula is shown in Table 1:

[0044] The preparation of coke oven ceramic hot-wiping supplement and the method of using the supplement to repair the coke oven are the same as in Example 1, and its main physical and chemical indicators are as follows:

[0045]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com