Film plated silver mirror, and preparation method thereof

A technology of silver mirror and silver layer, applied in the field of silver mirror, can solve the problems of decreased reflectivity of silver layer, shortened service life, etc., and achieve the effects of increasing adhesion, avoiding reaction, and excellent anti-scratch performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

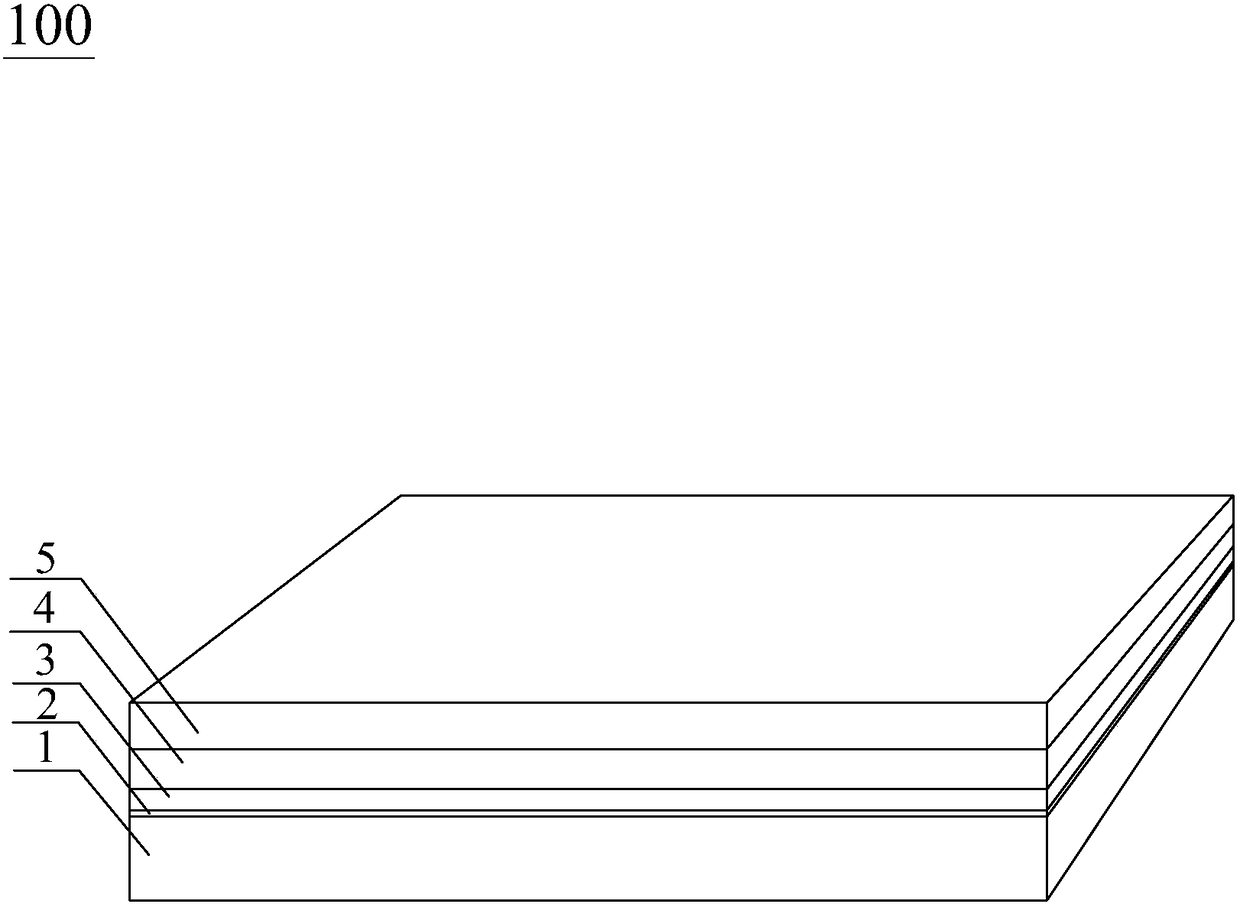

Image

Examples

preparation example Construction

[0022] The present invention also comprises the preparation method of coated silver mirror, comprises the following steps:

[0023] a. cutting the glass substrate 1;

[0024] b. cleaning the glass substrate 1 after step a;

[0025] c. Plating a silver layer 3 , a transition layer 4 and a silicone oil layer 5 on one side of the glass substrate 1 processed in step b in sequence.

[0026] In addition, in the process of step c, an adhesion layer 2 is also provided between the glass substrate 1 and the silver layer 3. The adhesion layer 2 is plated on the glass substrate 1, and then the surface of the adhesion layer 2 is plated with the silver layer 3, Transition layer 4 and silicone oil layer 5.

[0027] Adhesion layer 2, silver layer 3, transition layer 4, and silicone oil layer 5 can be coated by vacuum magnetron sputtering, and the glass substrate 1 is cut first, which can reduce the later cutting process of the product and make the coated silver mirror The cutting part is p...

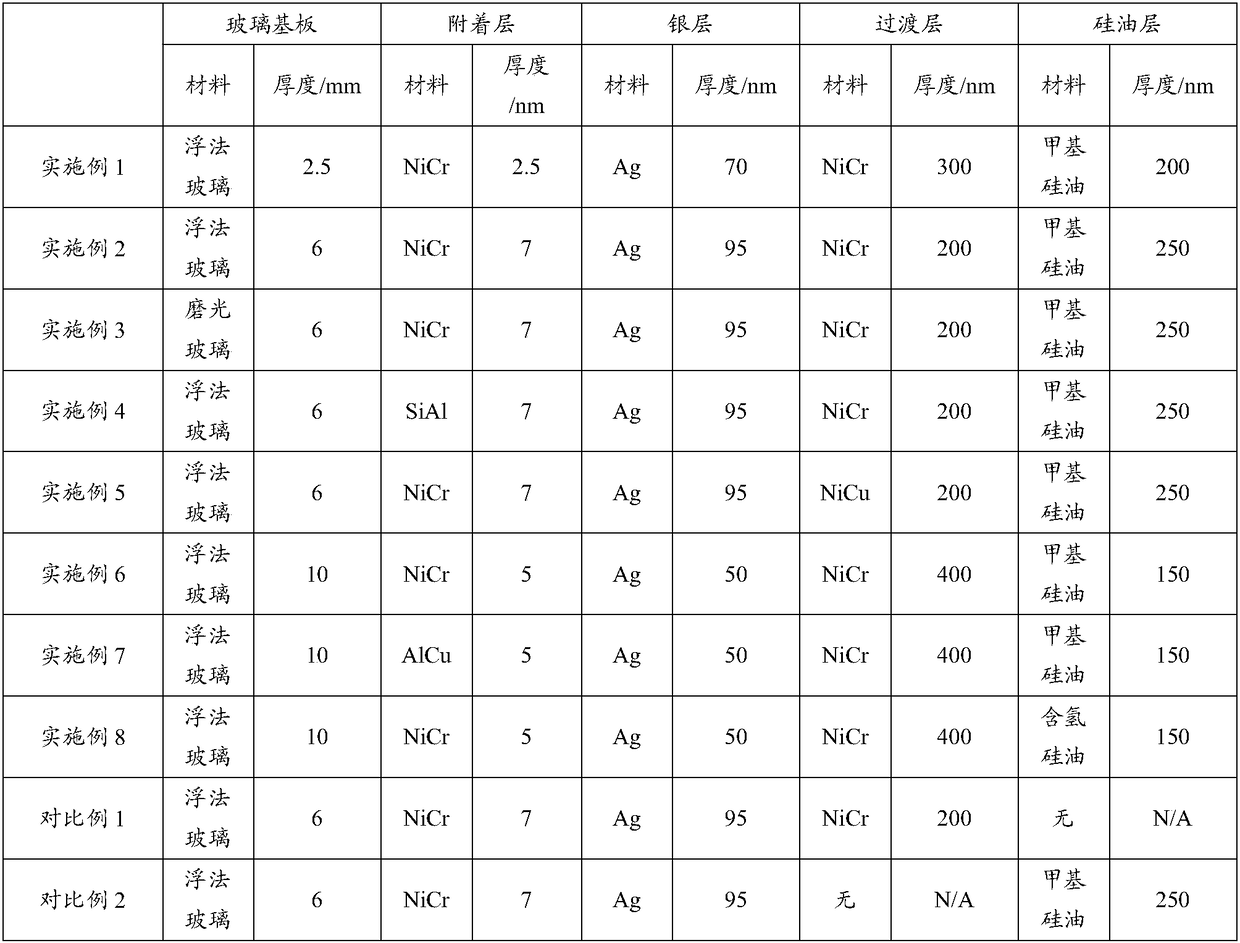

Embodiment 1

[0030] Composition of coated silver mirror:

[0031] Glass substrate: float glass with a thickness of 2.5mm;

[0032] Adhesion layer: nickel-chromium alloy layer with a thickness of 2.5nm;

[0033] Silver layer with a thickness of 70nm;

[0034] Transition layer: nickel-chromium alloy layer with a thickness of 300nm;

[0035] Silicone oil layer: a methyl silicone oil layer with a thickness of 200nm.

[0036] Preparation of coated silver mirror:

[0037] Take the 2.5mm float glass and cut it into the size required by the product, and clean the surface with inorganic acid, then fix it in the vacuum magnetron sputtering coating machine, and then set the nickel-chromium alloy target material of the adhesion layer After completion, perform magnetron sputtering coating on one side of the float glass, stop the coating operation when the coating thickness of the adhesion layer reaches 2.5nm, replace it with a silver layer target and start the coating operation again, and stop when...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com