Novel alumite

An anodized aluminum, a new type of technology, applied in the field of hot stamping materials, can solve the problems of water resistance, corrosion resistance, wear resistance of the anodized aluminum, influence on the conductive effect, and the effect of the duration of the hot stamping effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

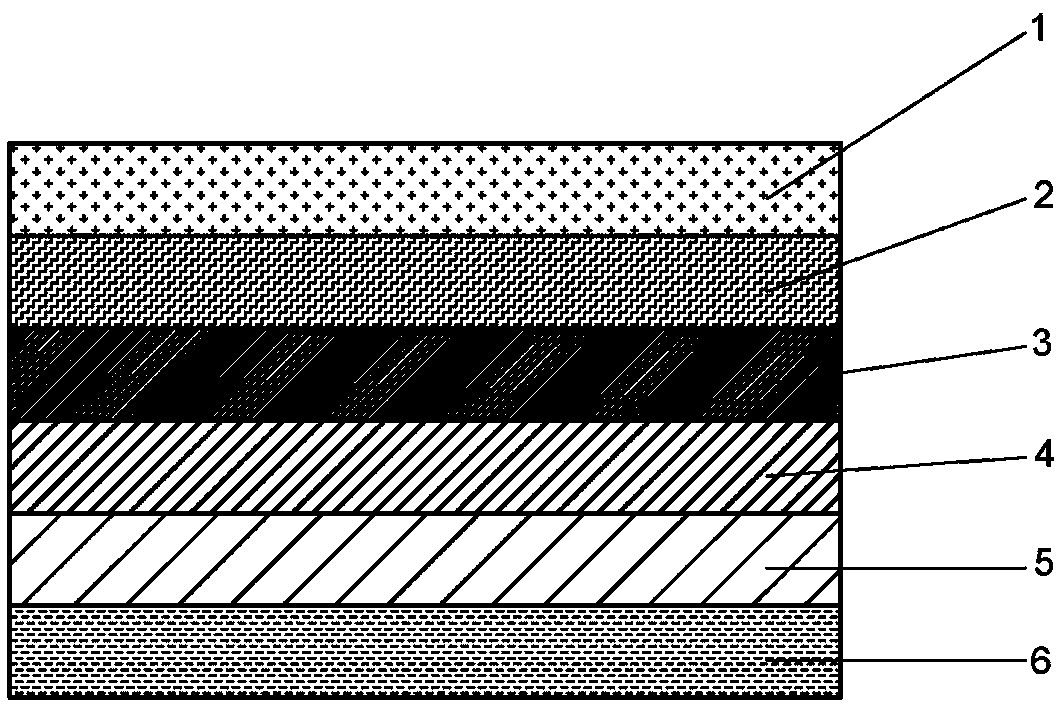

[0008] Below in conjunction with accompanying drawing, the present invention will be further described.

[0009] A new type of electrochemical aluminum, such as figure 1 As shown, the present invention is provided with a base film layer 6, a peeling layer 5, a colored layer 3, an aluminized layer 2, and an adhesive layer 1 in sequence. In addition, a layer of carbon fiber layer is also arranged between the peeling layer 5 and the colored layer 3. . Wherein the base film layer 6, the peeling layer 5, the colored layer 3, the aluminized layer 2, and the adhesive layer 1 are all the same as ordinary anodized aluminum. For example, the base film layer 6 is made of 16um thick biaxially stretched polyester film, the peeling layer 5 is mainly coated with silicone resin, the colored layer 3 mainly includes synthetic resin and dye, and the aluminized layer 2 is melted and continuous by aluminum wire. It is evaporated to the color layer of the film to form, and the adhesive layer 1 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com