A stacked solar module string welding machine

A technology of solar modules and stringer welding machines, which can be applied to welding equipment, electrical components, semiconductor devices, etc., and can solve problems such as easy damage and affecting production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

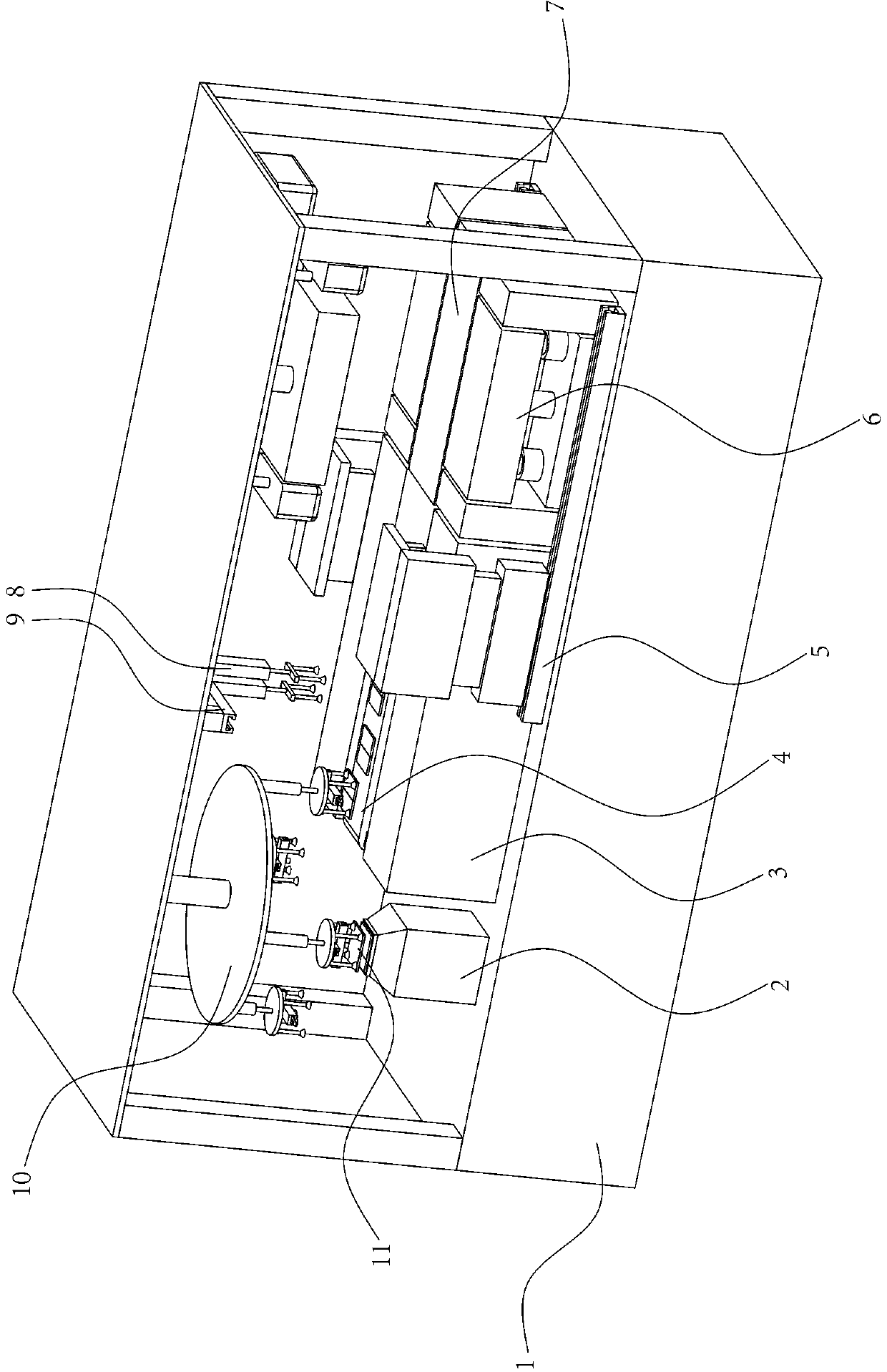

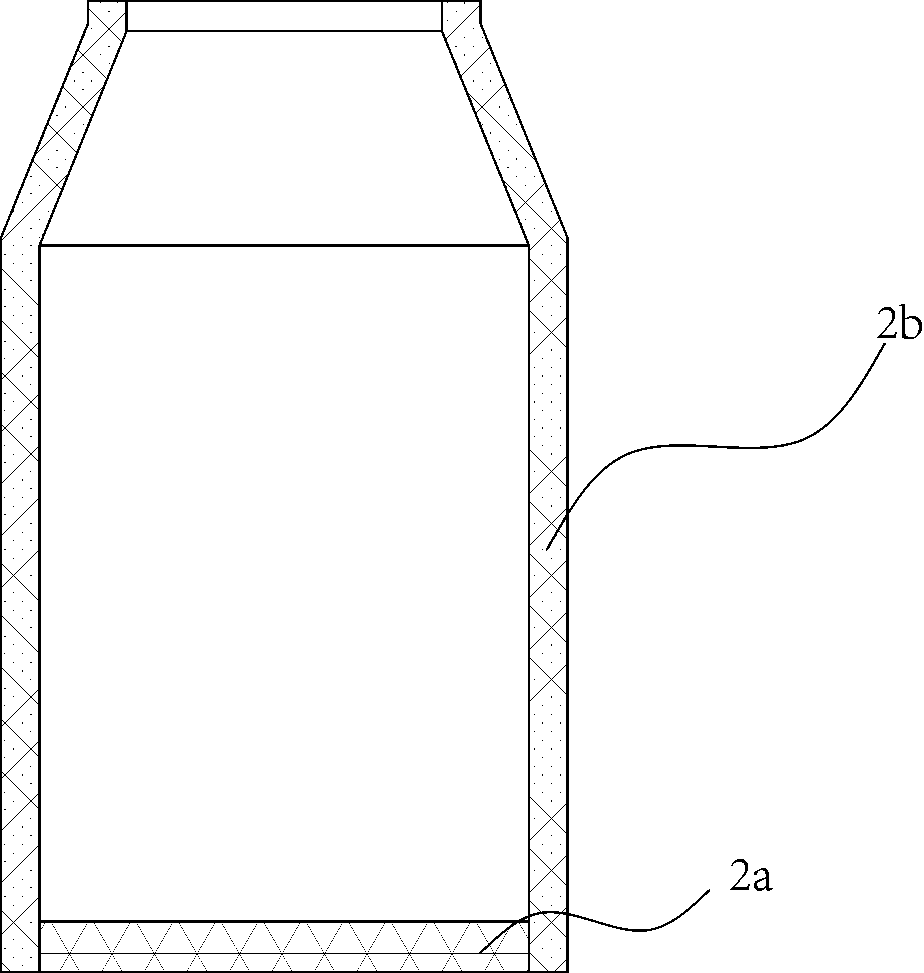

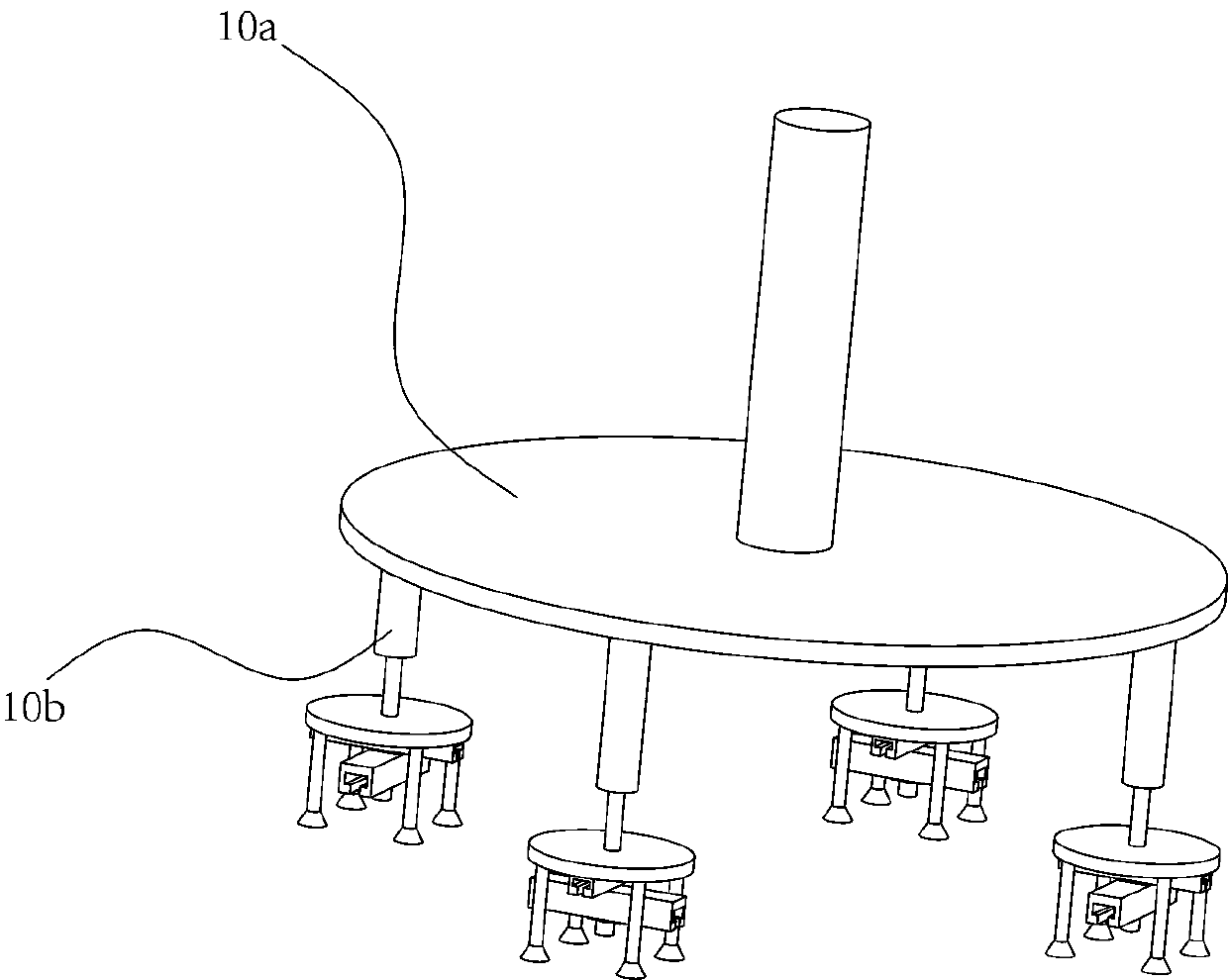

[0014] Such as figure 1 , 2 As shown, a stacked solar module stringer includes a frame on which a feeding device and an unloading device are arranged, and two fixed support platforms 6a are arranged at intervals on the frame, and each of the A briquetting block 6b is arranged above the fixed support table 6a, and the edges of the briquetting block 6b are provided with rounded corners. A lifting platform 6c is provided, a heating device 6d is arranged above the lifting platform 6c, and a support column 6f is arranged below the lifting platform 6c, and the support column 6f is inserted into a guide sleeve 6g fixed on the frame Inside, a hydraulic cylinder 6e is also connected below the lifting table 6c, and the hydraulic cylinder 6e includes a first hydraulic chamber 6e1 and a second hydraulic chamber communicated with each other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com