Household waste incineration fly ash cyclic utilization method

A domestic waste incineration and waste incineration technology, which is applied to chemical instruments and methods, solid waste removal, transportation and packaging, etc., can solve the problems of inability to realize continuous industrial application, insufficient exposure of active ingredients, and low recycling rate , to avoid equipment blockage accidents, reduce processing difficulty, and improve utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

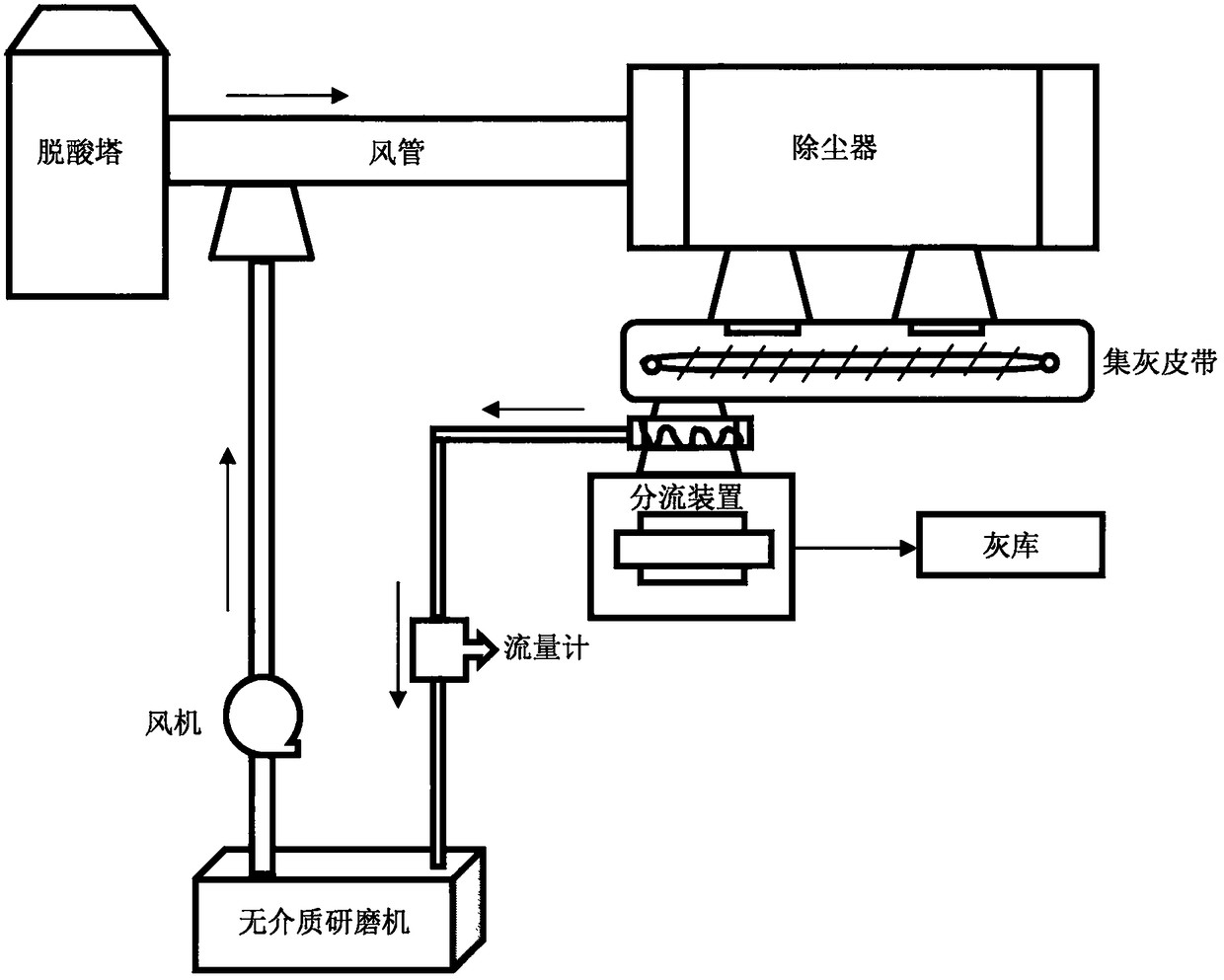

[0024] (1) Install a shunt device and a flow meter at the outlet of the ash conveying equipment of the dust collector of the waste incineration flue gas treatment system, adjust the opening of the shunt device to control the quality of the fly ash that circulates into the ultrafine pulverizer and the fly ash that is discharged into the fly ash storage The mass ratio of fly ash in the warehouse is 1:5;

[0025] (2) After the fly ash enters the grinding chamber of the superfine powder mill, it is pulverized by impact, shearing, rolling and grinding, and the ground powder is brought into the powder classifier by the suction of the high-pressure centrifugal fan, and finely ground. The fine powder with a fineness requirement of 5-50 μm passes through the blades of the powder classifier with the airflow and enters the deacidification reaction tower of the waste incineration flue gas treatment system. Return to the grinding bin to continue grinding;

[0026] (3) When the fly ash is ...

Embodiment 2

[0031] (1) Install a shunt device and a flow meter at the outlet of the dust collector ash conveying equipment of the waste incineration flue gas treatment system, adjust the opening of the shunt device to control the quality of the fly ash that circulates into the Raymond mill and discharge into the fly ash storage The mass ratio of fly ash is 1:1;

[0032] (2) After the fly ash enters the grinding chamber of the Raymond mill, it is pulverized by impact, shearing, rolling and grinding, and the ground powder is brought into the powder classifier by the suction of the high-pressure centrifugal fan. The fine powder that is required to reach 30-50 μm passes through the blades of the powder classifier with the airflow and enters the air duct between the outlet of the deacidification reaction tower of the waste incineration flue gas treatment system and the inlet of the dust collector. Coarse particles that do not meet the fineness requirements After being intercepted and thrown ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com