Plastic dipping machine

A technology of dipping and plasticizing furnaces, applied in the field of dipping machines, can solve the problems of lower production efficiency, uneven dipping, and affect product quality, and achieve high production efficiency, complete powder sticking, and good product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

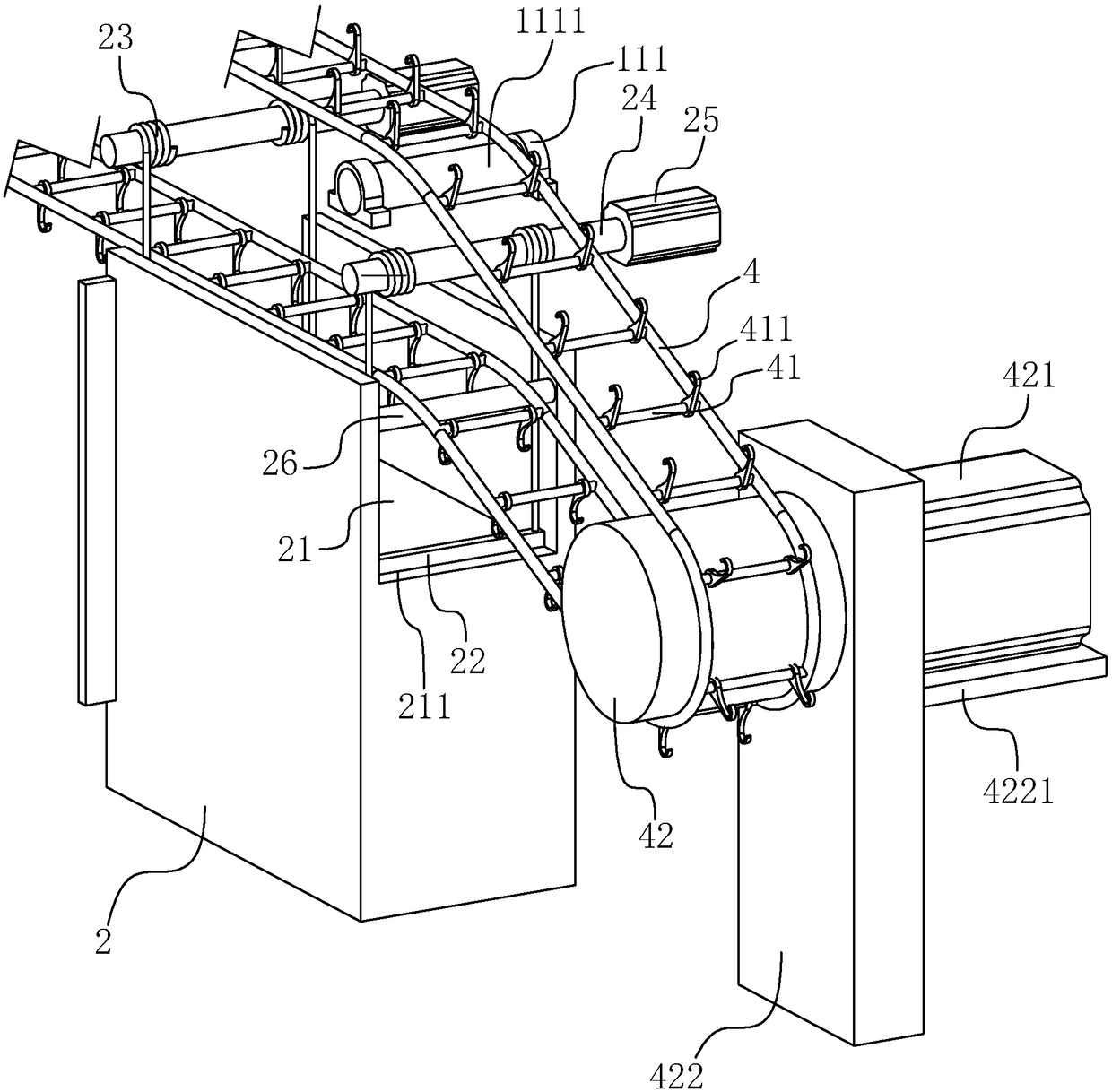

[0041] Embodiment: a kind of dipping machine, combined with figure 1 and figure 2 , including a plastic dipping furnace 1 placed on the ground, a heating furnace 2 connected to one side of the plastic dipping furnace 1 and a plasticizing furnace 3 connected to the other side of the plastic dipping furnace 1 . (The heating furnace 2 and the plasticizing furnace 3 are all prior art, and are not repeated here.) The plasticizing furnace 1, the heating furnace 2 and the plasticizing furnace 3 are jointly connected with a conveying chain 4, and the conveying chain 4 has two And they are arranged parallel to each other, and a plurality of connecting rods 41 are connected in the middle of the two transmission chains 4, and a plurality of hooks 411 are fixedly connected on the connecting rods 41.

[0042] The conveyor chain 4 passes through the plasticizing furnace 3, the heating furnace 2 and the plasticizing furnace 1 and bends downwards at both ends of the heating furnace 2 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com