Novel structure motor driver

A technology of motor driver and new structure, which is applied in the direction of motor control, AC motor control, and transformation of equipment structure parts, etc. It can solve problems such as unreasonable capacitance distribution, difficult circuit layout and mechanical installation layout, and fast temperature rise of the driver. Improve the current passing ability, facilitate automatic production, and have the effect of strong current passing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

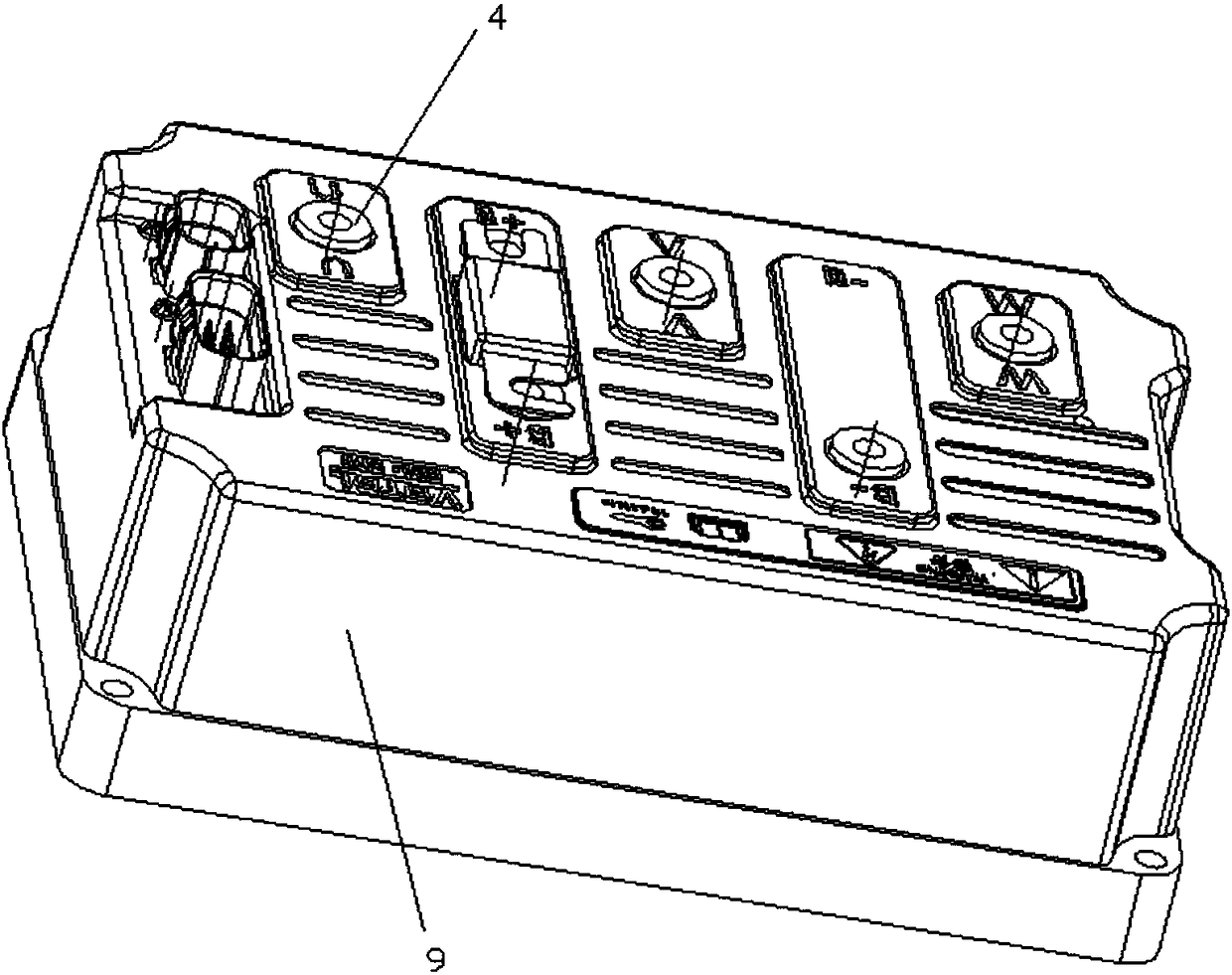

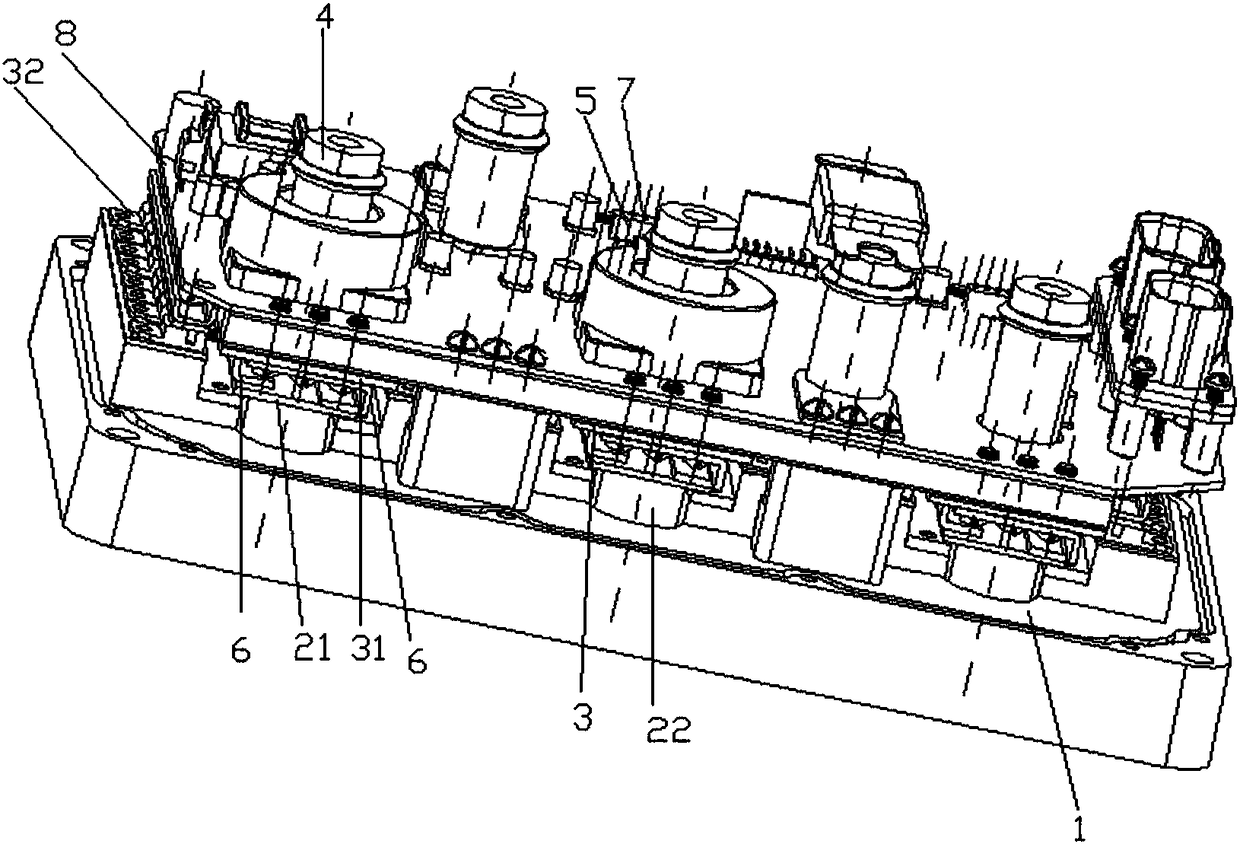

[0028] Such as figure 1 , 2 As shown in and 3, a motor driver with a new structure includes a capacitor module part 2 and a power drive module part 3, an aluminum shell 1 and a plastic shell 10 for encapsulation, and the aluminum shell 1 is used as a shell to carry the capacitor module part 2 and The power drive module part 3 and the capacitor module part 2 include six compensating and filtering capacitors 22 uniformly distributed in a row on the capacitor PCB board 21. The capacitors 22 are embedded in the aluminum shell 1. The gap between them is filled with thermal conductive silicone grease to enhance the thermal conductivity, and the capacitor 22 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com