Spring and polygonal vertical linear vibration motor

A vertical linear, vibration motor technology, applied in electrical components, electromechanical devices, etc., can solve the problems of large thickness of circular vibration motor, short vibration fatigue life, easy mutual interference of springs, etc., to improve the lack of spring form, vibration fatigue, etc. Long life and the effect of filling the gap in the market

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

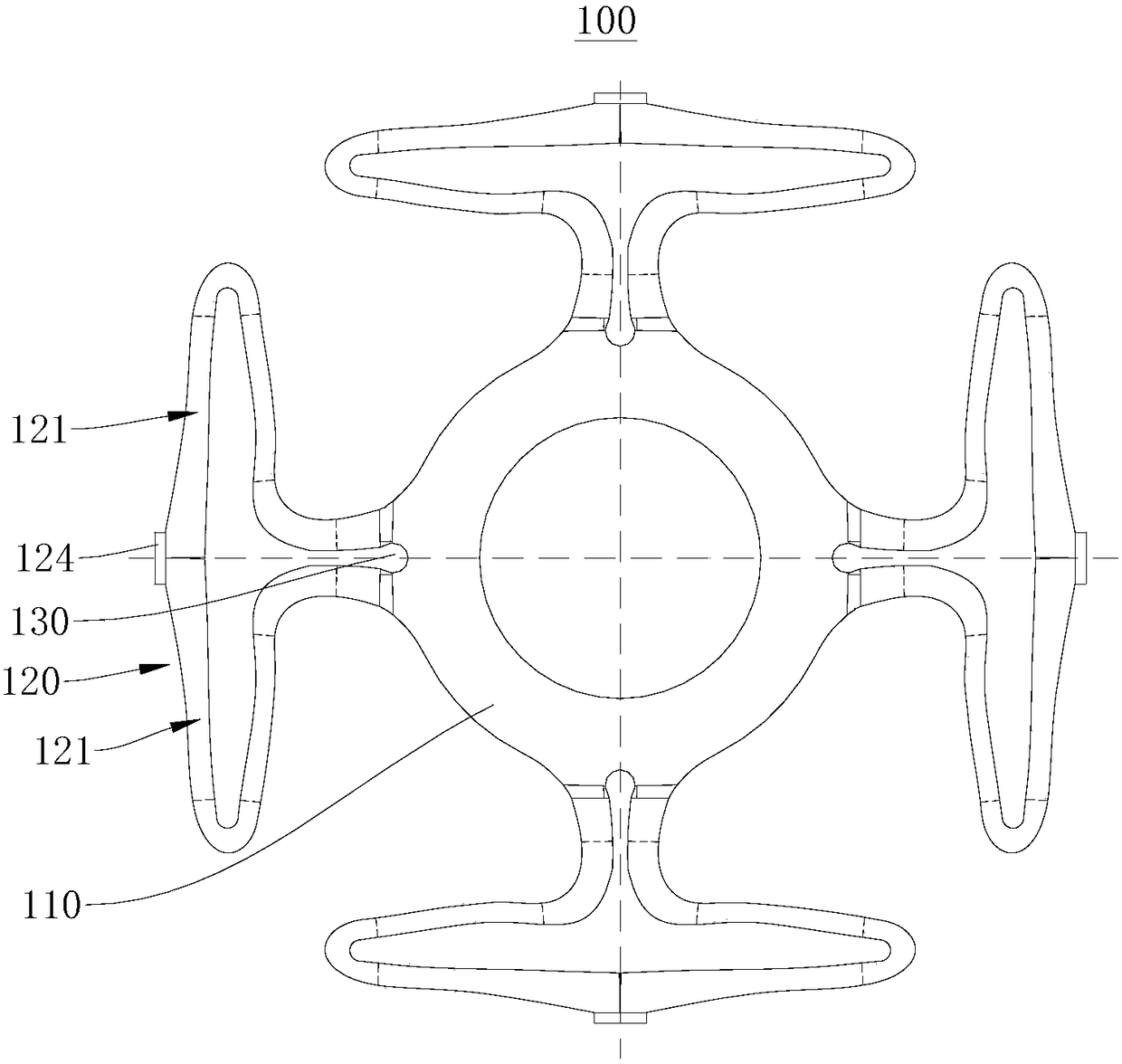

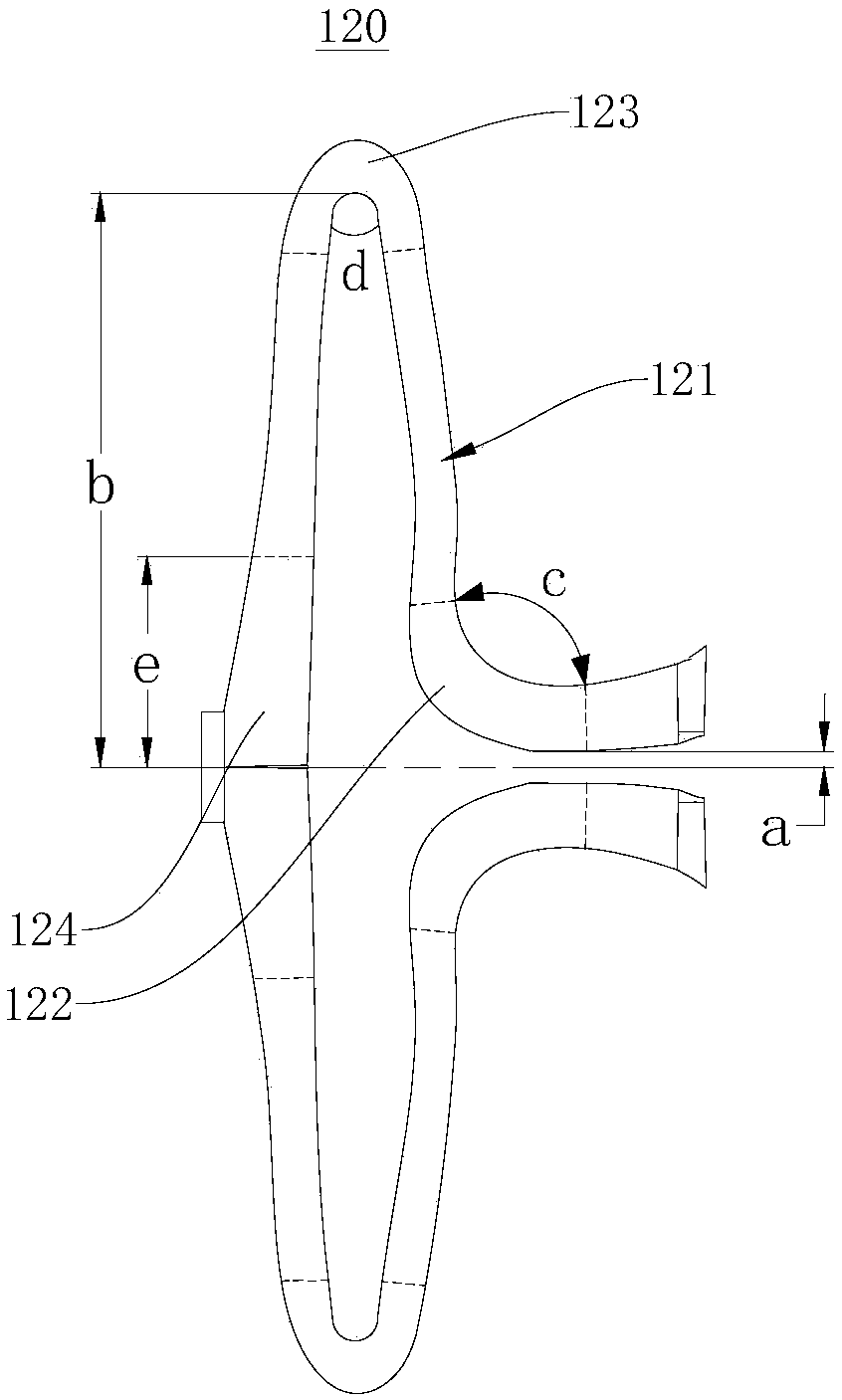

[0039] see figure 1 , the dotted line on the sub-arm 121 in the figure represents the dividing line between each part, the shape of each part is not required to be completely consistent with the figure, and the shape of each part in the figure is only for illustration. The straight dotted line between the two sub-arms 121 in the figure represents the symmetry line of the arm assembly 120 .

[0040] This embodiment provides a spring 100, which is a cone spring. The spring 100 is mainly used in the polygonal vertical linear vibration motor 200 . The spring 100 includes an inner ring 110 and a plurality of moment arm assemblies 120 connected to the outer periphery of the inner ring 110 . In this embodiment, the number of arm assemblies 120 is four. Four moment arm assemblies 120 are evenly connected to the outer circumference of the inner ring 110 .

[0041] The arm assembly 120 includes two sub-arms 121 arranged symmetrically to each other. One end of the two sub-arms 121 is...

no. 2 example

[0060] This embodiment provides a spring 100 , which is similar in structure to the spring 100 provided in the first embodiment, except that the inner ring 110 is connected to the moment arm assembly 120 through a connecting section 140 .

[0061] see Figure 5 , the spring 100 further includes a connection section 140 , and the connection section 140 is connected between the inner ring 110 and the moment arm assembly 120 . Specifically, the moment arm assembly 120 includes two sub-moment arms 121 arranged symmetrically to each other. One ends of the two sub-moment arms 121 are connected to the connecting section 140, and the other ends of the two sub-moment arms 121 are connected.

[0062] The connection section 140 in this embodiment is equivalent to the first curved portion 122 in the first embodiment and the part between the first curved portion 122 and the inner ring 110 is formed by merging. The moment arm assembly 120 in this embodiment is equivalent to the remaining p...

no. 3 example

[0065] This embodiment provides a spring 100, which is similar in structure to the spring 100 provided in the first embodiment or the second embodiment, except that the spring 100 in this embodiment is a flat spring. Specifically, the inner ring 110 of the spring 100 and the moment arm assembly 120 are located in the same plane.

[0066] This embodiment also provides a polygonal vertical linear vibration motor 200 using the above-mentioned spring 100 . Other structures of the spring 100 and the polygonal vertical linear vibration motor 200 provided in this embodiment are the same as the corresponding structures in the first embodiment, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com