Sieving machine operation amplitude monitoring system and monitoring method

A monitoring system and technology of vibrating screen machine, which are applied in measuring devices, measuring ultrasonic/sonic/infrasonic waves, instruments, etc., can solve the problems of running amplitude without real-time feedback, inconvenient process, etc., to improve screening stability and product quality, The effect of facilitating equipment problems and reducing unnecessary losses

- Summary

- Abstract

- Description

- Claims

- Application Information

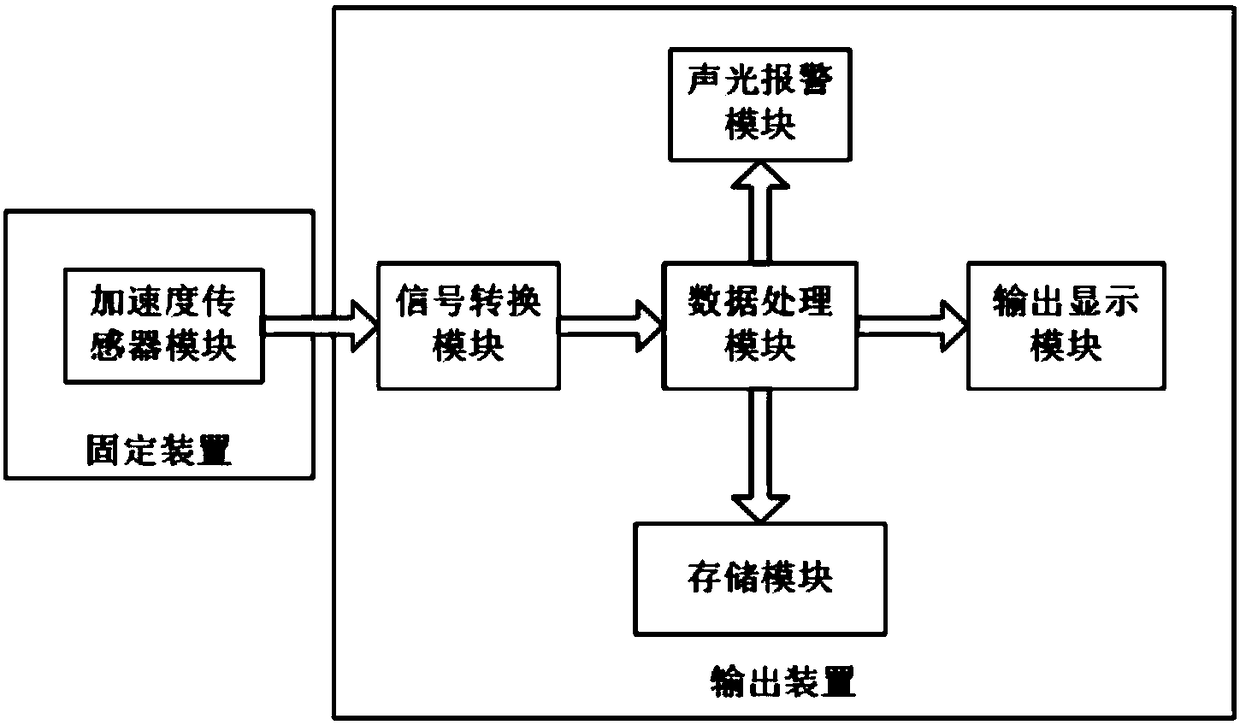

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

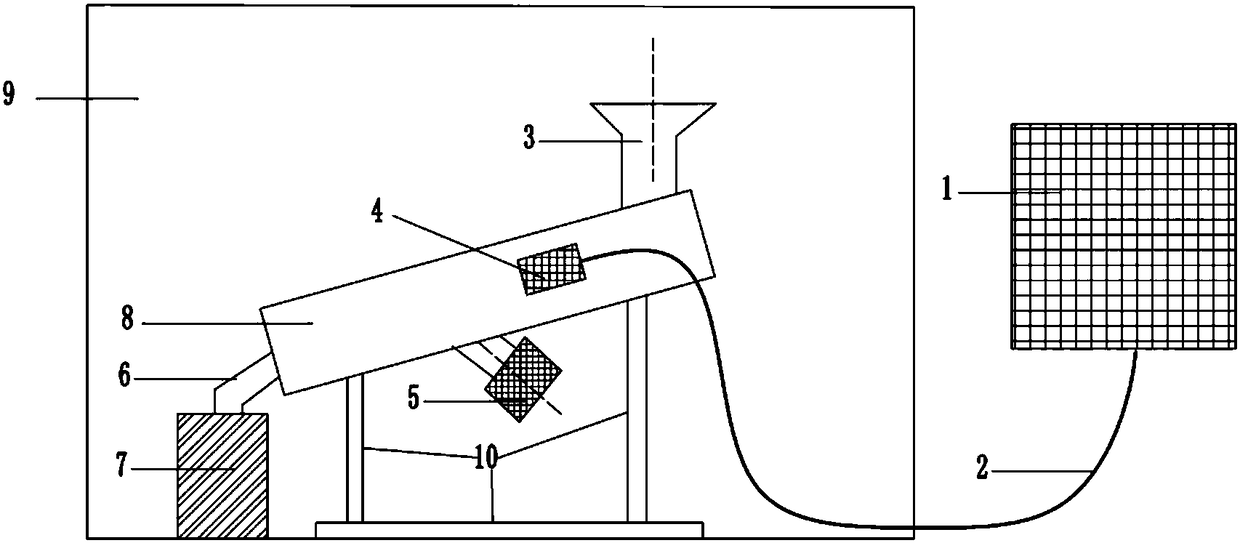

[0042] (1) As attached figure 2 As shown, the acceleration sensor module 4 is installed on the outer wall of the linear vibrating screen machine body 8, and the output device 1 composed of other modules is installed outside the working space 9 of the linear vibrating screen, and the two are connected by a connecting wire 2 with a shielding layer.

[0043] (2) When working from the linear vibrating sieve machine, after the inlet 3 of the linear vibrating sieve machine is put into the powder material, the sieving movement is carried out under the drive of its vibration source 5, and the particle size of the finished product obtained by detecting the discharge pipeline 6 of the linear vibrating sieve machine According to the situation and sieving rate, adjust the linear vibrating sieve machine to the best production process, and formulate a suitable standard process.

[0044] (3) The acceleration sensor module 4 collects the amplitude data in three directions of X / Y / Z in real ti...

Embodiment 2

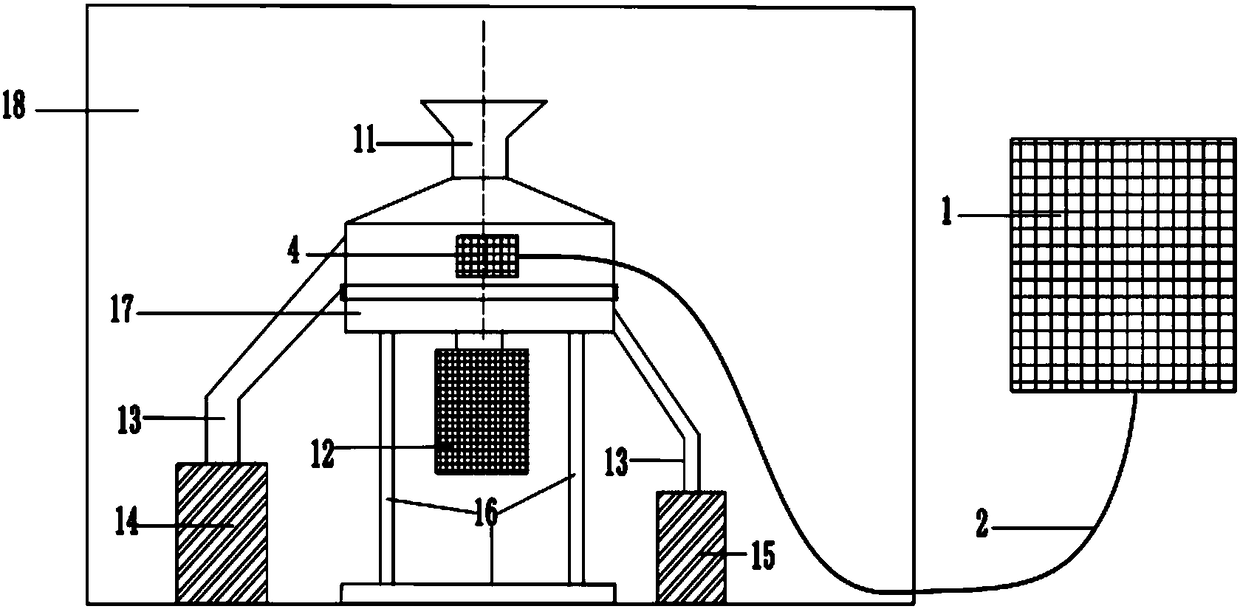

[0048] (1) As attached image 3 As shown, the device is installed on the outer wall of the body 16 of the rotary vibrating screen machine (circular vibrating screen machine). Here, the three-dimensional circular vibrating screen machine is taken as an example, wherein the acceleration sensor module 4 is installed on the outer wall of the circular vibrating screen machine body 17. The output device 1 composed of other modules is installed outside the working space 18 of the circular vibrating screen machine, and the two are connected by connecting wires 2 with a shielding layer.

[0049] (2) When working, after the feed port 11 of the circular vibrating sieve machine is put into the powder material, the sieving movement is carried out under the drive of its vibration source 12, and the particle size of the finished product obtained by detecting the discharge device 14 of the circular vibrating sieve machine, According to the sieving rate, adjust the circular vibrating sieve mac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com