Connection terminals between wires and components

A technology for connecting terminals and components, applied in the field of power electronic device connection, can solve problems such as heat burnout and poor contact, and achieve the effects of reducing heat burnout, improving connection quality and avoiding theft.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0021] In order to solve the problem that the copper wires in the outdoor power equipment such as the irrigation machine well metering box are easily stolen, or the components are poorly connected, easy to heat and burn, etc., the invention provides a connecting terminal between the wires and the components.

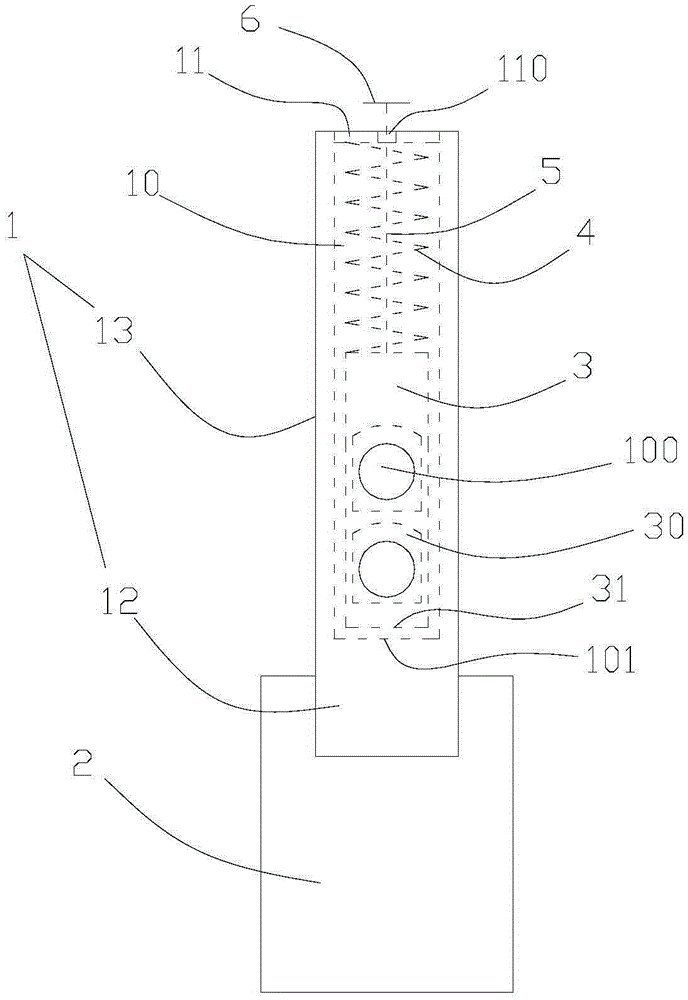

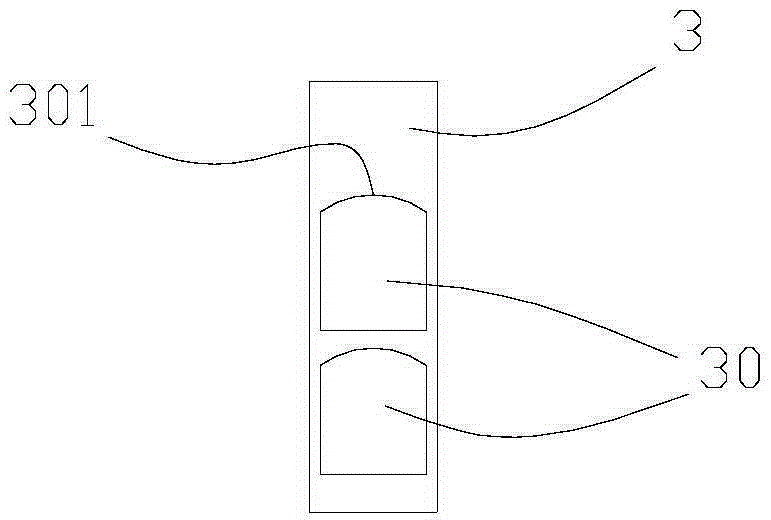

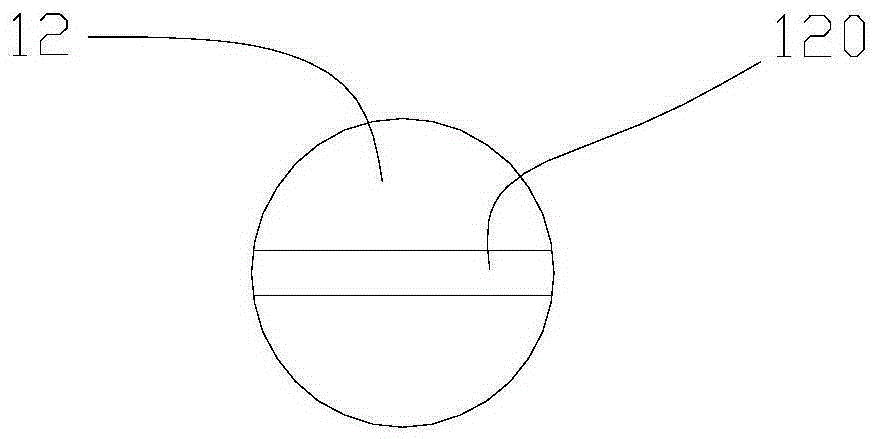

[0022] Such as figure 1 As shown, Embodiment 1 of the present invention mainly includes a connecting column 1 , a connecting plate 2 , a clamping column 3 , a spring 4 , and a driving structure composed of a pull wire 5 and a handle 6 .

[0023] The connecting plate 2 is made of copper material, and it is in the shape of a flat rectangular plate, and the front part is used for connecting with components. In the front section of the connecting plate 2, in order to facilitate connection with different components, structures such ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com