Amorphous silicon thin film battery tail gas treatment device

An amorphous silicon thin film, battery exhaust technology, applied in the combustion method, combustion type, incinerator and other directions, can solve the problems of low combustion efficiency, poor cleaning effect, increase the difficulty of exhaust gas treatment, etc., to achieve high combustion treatment efficiency, combustion Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

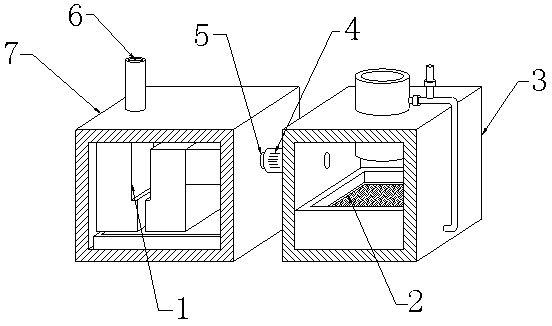

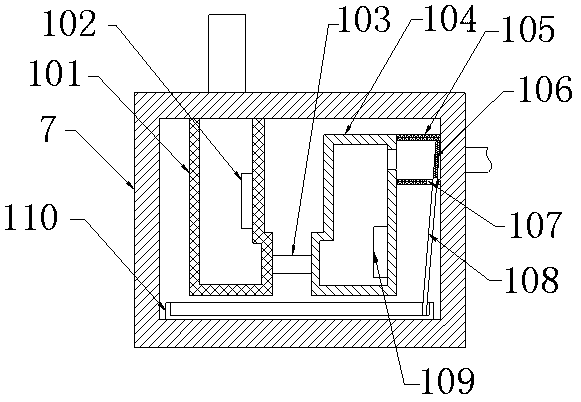

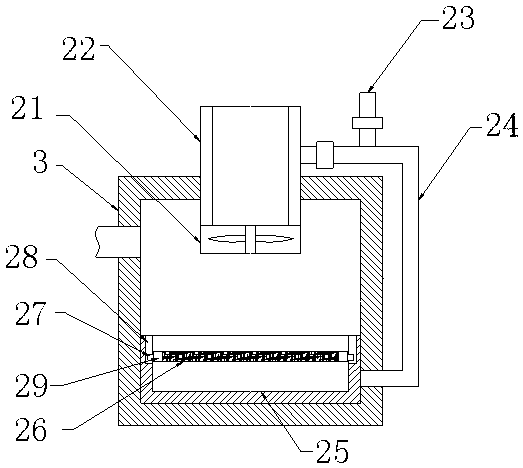

[0019] see Figure 1-Figure 3 , the present invention provides a technical solution: an amorphous silicon thin-film battery exhaust gas treatment device, including an aftertreatment box 3, a blower 4, a gas delivery pipe 5, an air intake pipe 6, a pretreatment box 7, an exhaust gas combustion mechanism 1, and an exhaust gas dust removal mechanism 2. The post-processing box 3 is set on the rear side of the pre-processing box 7, the blower 4 is set on the annular side of the air delivery pipe 5, the air delivery pipe 5 is installed on the right end surface of the pre-treatment box 7, and the left end of the air delivery pipe 5 is connected to the after-treatment box 3 connection, the intake pipe 6 is arranged on the left side of the upper end surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com