A pre-cleaning garbage incineration device

A waste incineration and washing technology, applied in incinerators, combustion types, combustion methods, etc., can solve the problems of increasing the time required for combustion, high water content in waste, and inability to remove it, so as to improve combustion efficiency and improve treatment efficiency. , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

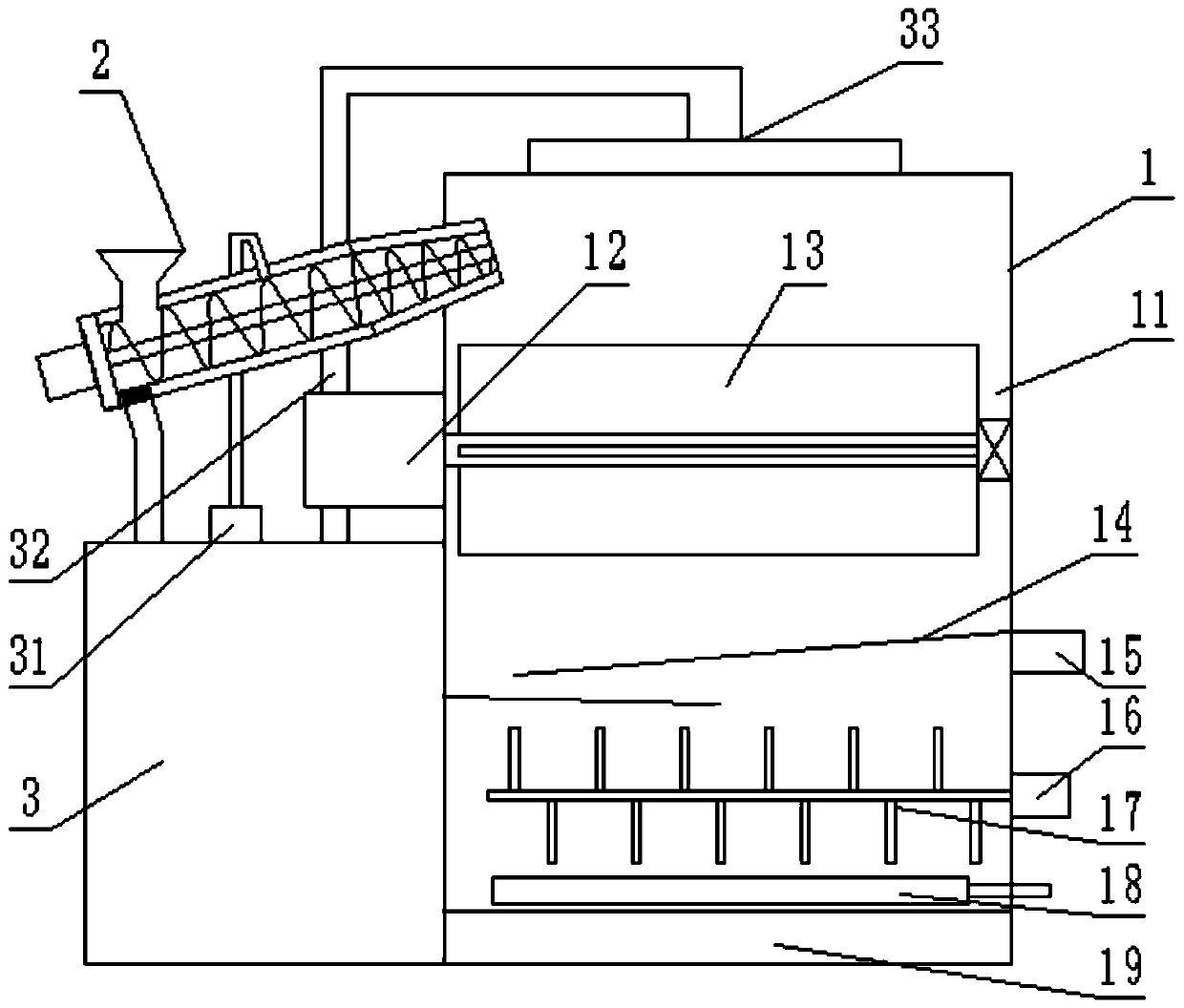

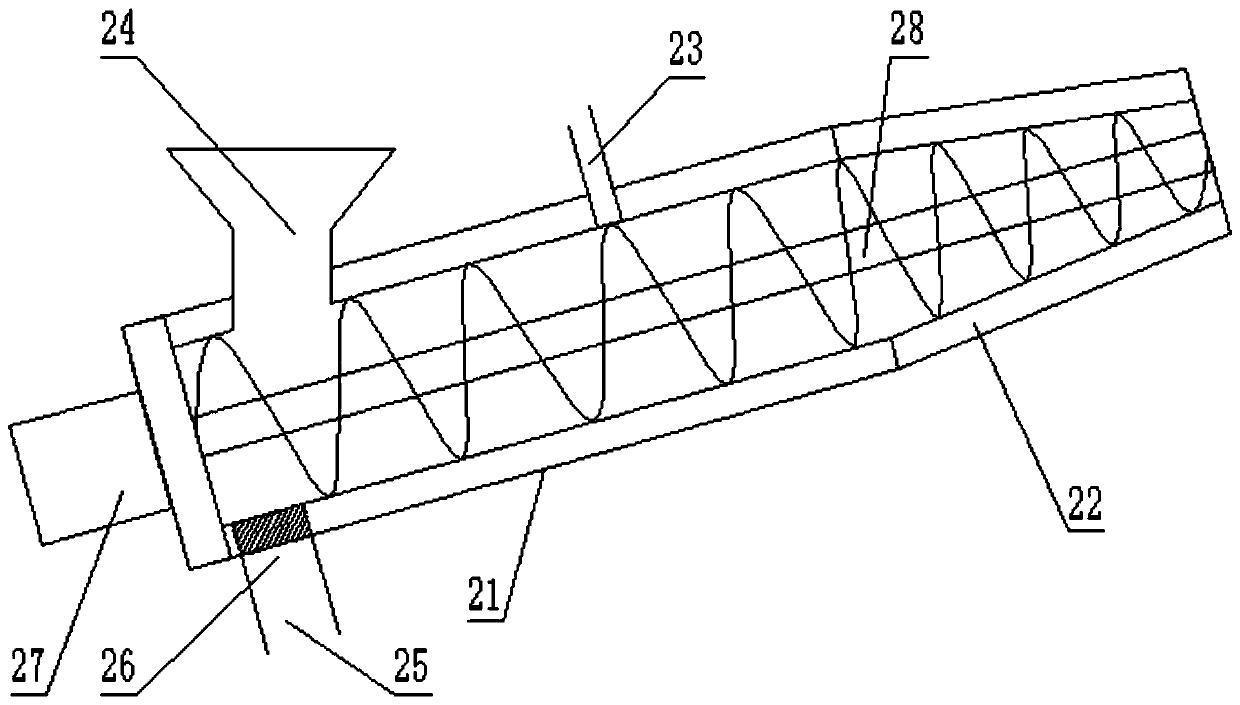

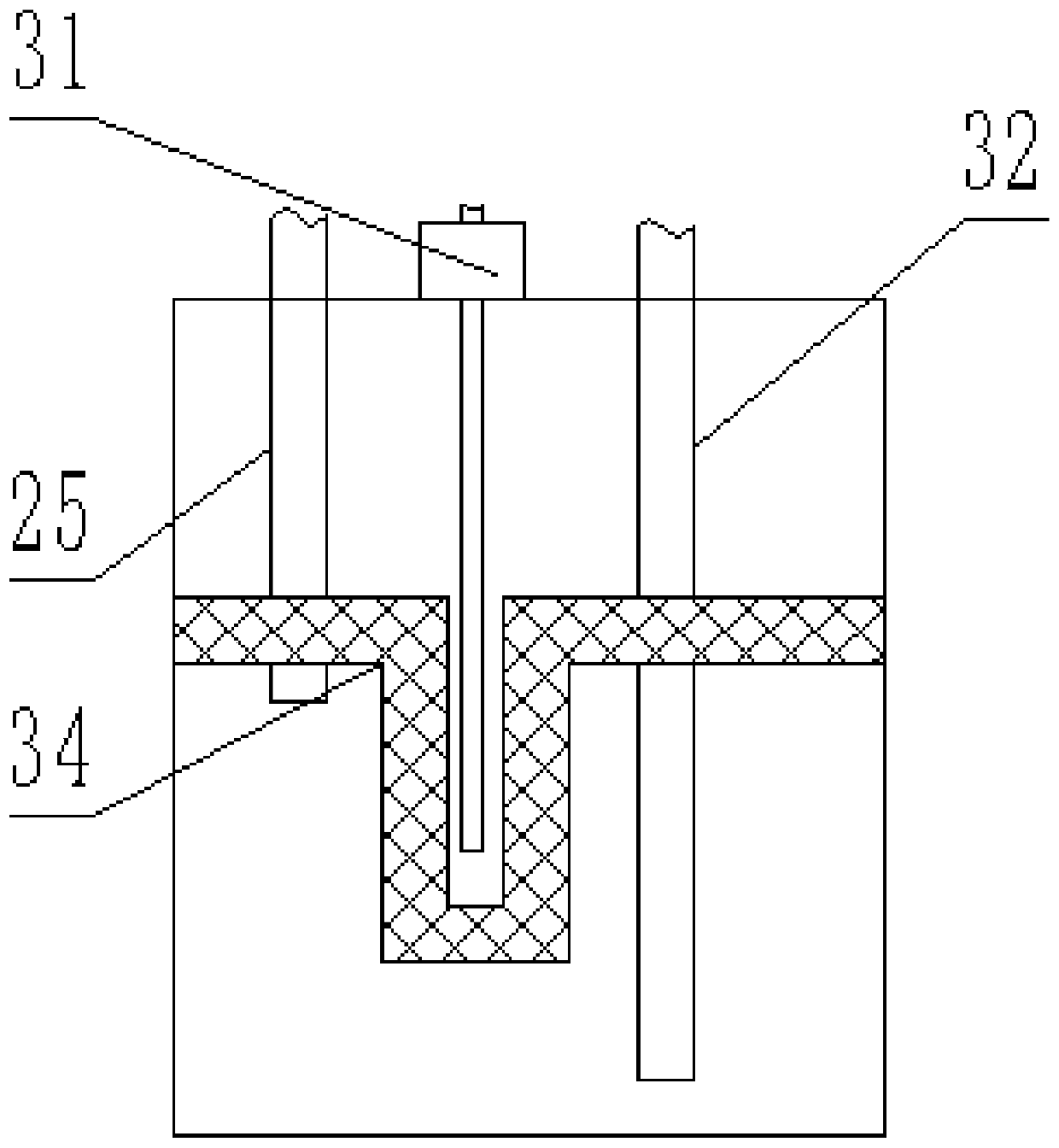

[0019] see Figure 1-3 , a pre-cleaning type garbage incinerator, comprising a furnace body 1, a water tank 3 located outside the furnace body 1 and arranged side by side with it, and a feeder 2 located above the water tank 3 and inserted into the furnace body 1 at the front end; the furnace body 1 The inside is provided with an equalizer 11, a guide plate 14 and a fire grate 18 sequentially from top to bottom, and the bottom of the furnace body 1 is a furnace ash layer 19; The rotating shaft is installed on the inner wall of the furnace body 1 and connected with the first motor 12 fixed on the outer wall of the furnace body 1; there are two guide plates 14 and they are symmetrically arranged on both sides of the furnace body 1. 1 side is also provided with an exhaust pipe 15, the exhaust pipe 15 is docked with the guide plate 14 at the top, and a second motor 16 is arranged below the exhaust pipe 15 and on the outer wall of the furnace body 1, and the second motor 16 The out...

Embodiment 2

[0023] The difference with Embodiment 1 is that an electric heater is also provided in the water tank 3, and the electric heater is a plurality of PTC heating tubes, and the electric heater is located below the filter screen 34, and the water in the water tank 3 is heated by the electric heater. Preheating allows the unit to be cleaned with hot water when the unit is first used.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com