Frequency conversion centrifugal pump optimal regulating method and system based on pressure pulsation

A technology of pressure pulsation and adjustment method, which is applied to the components of pumping devices for elastic fluids, non-variable pumps, pumps, etc., which can solve problems such as unstable flow, long cycle, and difficult capture, and achieve safety and stability The effect of operational assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

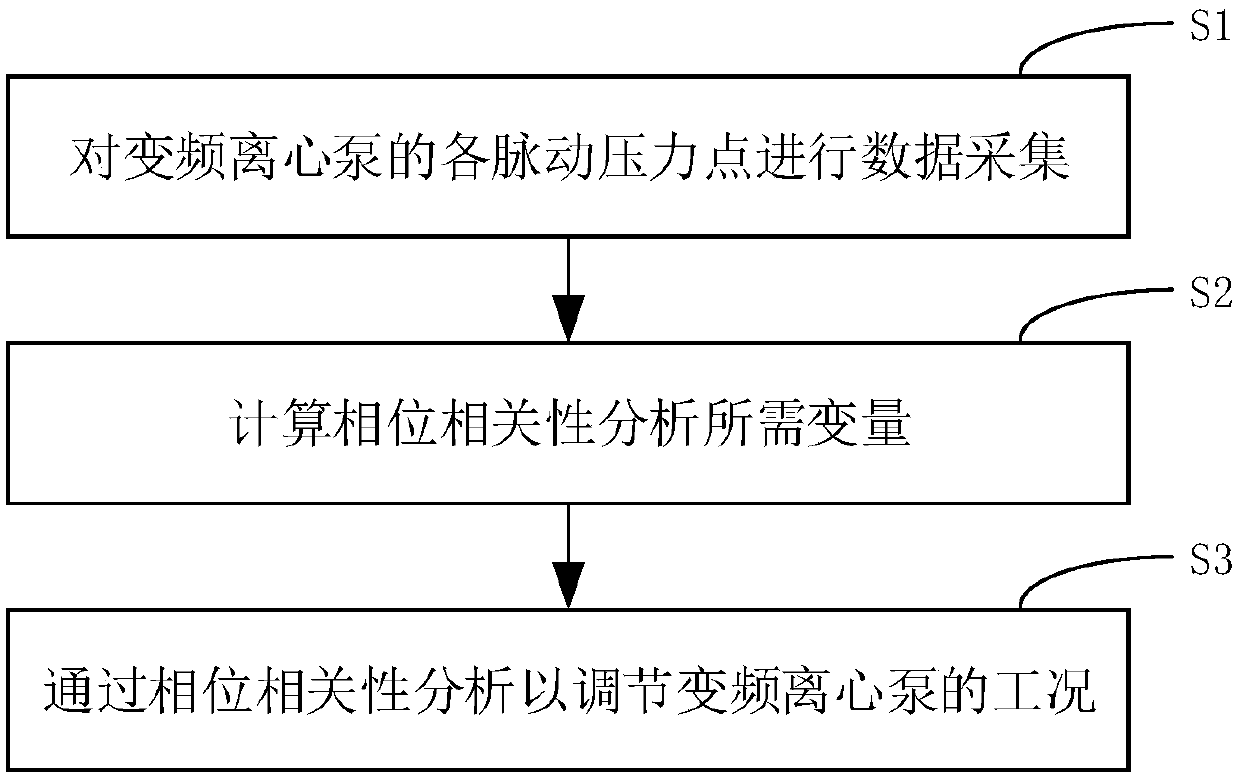

[0065] Such as figure 1 As shown, this embodiment provides an optimal adjustment method for a variable frequency centrifugal pump, including the following steps:

[0066] Step S1, collecting data at each pressure pulsation monitoring point of the variable frequency centrifugal pump;

[0067] Step S2, calculating the variables required for phase correlation analysis; and

[0068] Step S3, adjusting the working conditions of the variable frequency centrifugal pump through phase correlation analysis.

[0069] The method for collecting data at each pressure pulsation monitoring point of the variable frequency centrifugal pump in the step S1 includes:

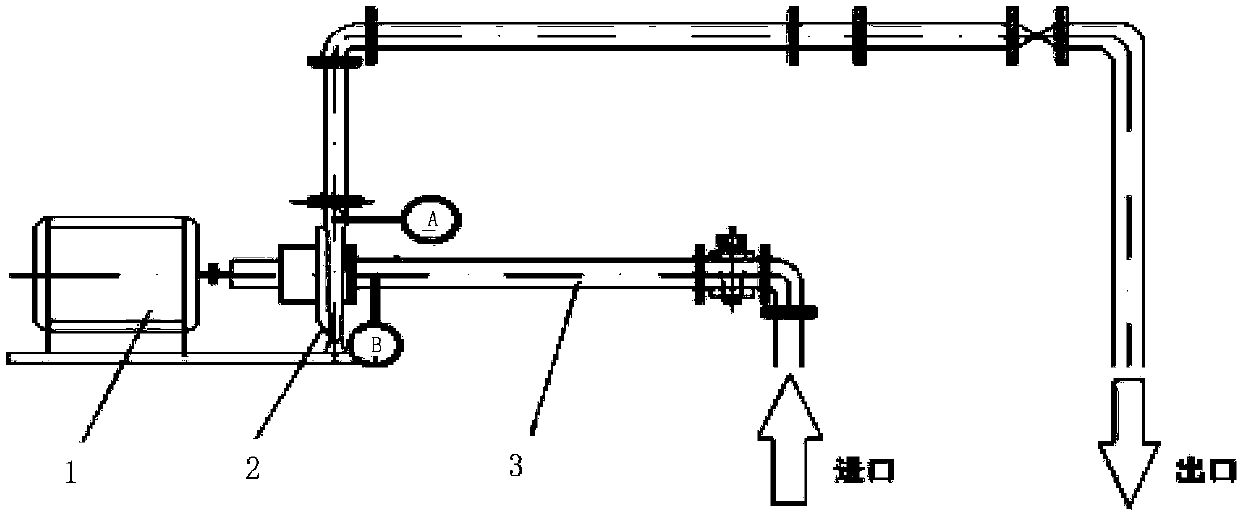

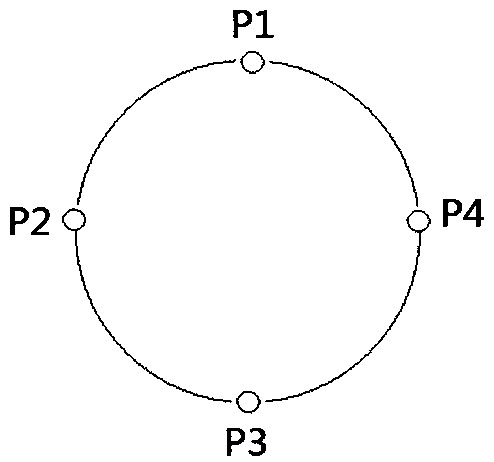

[0070] Such as figure 2 Shown is a schematic diagram of the pump device. Section A and section B in the figure are respectively located at the inlet section or outlet section of the pump. You can choose the appropriate section by yourself. Such as image 3 As shown, pressure pulsation monitoring points uniformly distributed in t...

Embodiment 2

[0125] On the basis of the above-mentioned embodiment 1, this embodiment also provides a variable frequency centrifugal pump optimization adjustment system, including:

[0126] A number of pressure pulsation sensors are evenly distributed in the circumferential direction of the inlet section or outlet section of the variable frequency centrifugal pump;

[0127] The processor module calculates the characteristic frequency of each pulsating pressure data, and adjusts the working condition of the variable frequency centrifugal pump through phase correlation analysis.

[0128] In this embodiment, the corresponding working process of the processor module has been described in detail in Embodiment 1, and will not be repeated here.

[0129] The present invention only needs to arrange a pressure pulsation sensor at the inlet section or outlet section of the pump, without damaging the frequency conversion centrifugal pump, it can relatively judge the unstable flow with the rotation com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com