High temperature-resistant heat-sealing adhesive for high-speed medicine packaging machine for medicine blister packaging, and preparation method thereof

A blister packaging, high-speed technology, applied in adhesives, epoxy resin adhesives, grafted polymer adhesives, etc., can solve problems such as poor adhesion, non-existence, poor hydrolysis resistance, etc., and achieve good stability of the adhesive layer , wide application range, improved hydrolysis resistance and high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

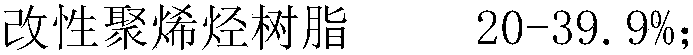

Method used

Image

Examples

Embodiment 1

[0039] This embodiment relates to a heat-resistant heat-seal adhesive used in a high-speed drug blister packaging machine for pharmaceutical blister packaging. The specific formula is shown in Table 1. The preparation method includes the following steps:

[0040] (1) Put all the solvents into the reactor according to the ratio and stir;

[0041] (2) Keep stirring and put the modified polyolefin and modified epoxy into the reactor in turn, and stir for 1-2 hours;

[0042] (3) Slowly put the auxiliary agent into the reaction kettle after mixing uniformly, and stir at high speed for 0.5-1 hour;

[0043] (4) When the mixture is evenly mixed, stop and mature for 10-12 hours;

[0044] (5) Measure the solid content and adjust it to the theoretical value;

[0045] (6) Stir slowly again for 1-2 hours, cool, filter with 250 mesh filter, weigh and pack.

Embodiment 2-5

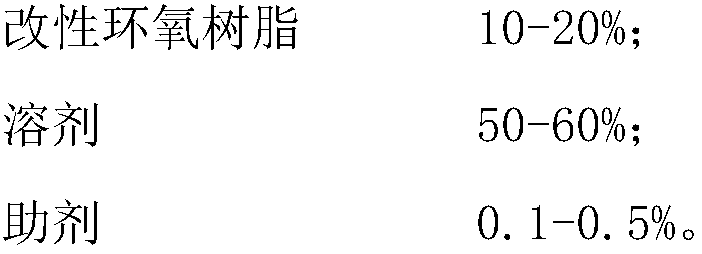

[0047] Examples 2-5 respectively relate to a heat-resistant heat-seal adhesive used in a high-speed packaging machine for blister packaging of medicines. The preparation method thereof is the same as that of Example 1. The specific formula is shown in Table 1.

[0048] Table 1

[0049]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com