Method for reducing abrasion to bentonite gel extraction centrifugal machine from silicon particles

A centrifuge and soil gel technology, applied in chemical instruments and methods, solid separation, wet separation, etc., can solve the problems of large loss of bentonite colloid, increased grinding cost, low classification efficiency, etc., to improve processing capacity, Improved production capacity and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with examples, which are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

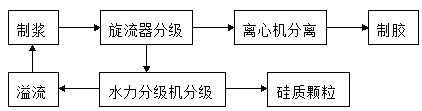

[0018] Such as figure 1 As shown, the present embodiment provides a method for reducing the abrasion of the siliceous particles to the bentonite gel extraction centrifuge, comprising the following steps:

[0019] Step 1: pulping: mix and stir bentonite raw ore, compounding agent and water to make pulp;

[0020] Step 2: Classification 1: Use a hydrocyclone to classify the pulp, separate the pulp, and take the overflow into the centrifuge;

[0021] Step 3: Classification 2: The underflow classified by the hydrocyclone in step 2 is classified by a hydraulic classifier, and the overflow fine particles are returned to step 1 for pulping, and the underflow is siliceous particle tailings;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com