Manufacturing method of composite heat dissipation material

A technology of composite heat-dissipating material and manufacturing method, which is applied to electrochemical generators, electrical components, circuits, etc., can solve the problems of direct contact with cooling plates, reduced heat transfer efficiency, insufficient strength of thermally conductive materials, etc., to improve insulation reliability, The effect of efficient heat conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

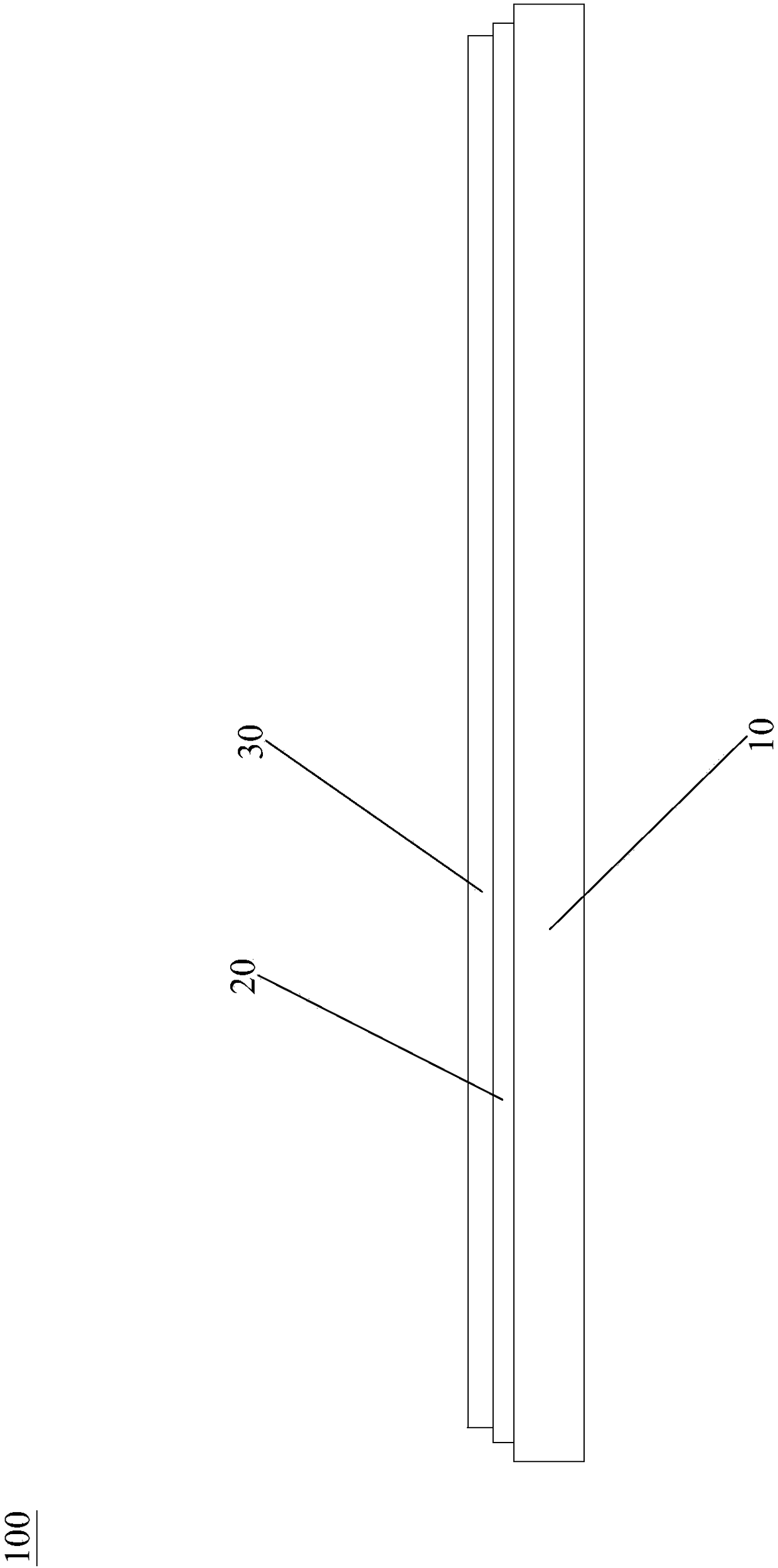

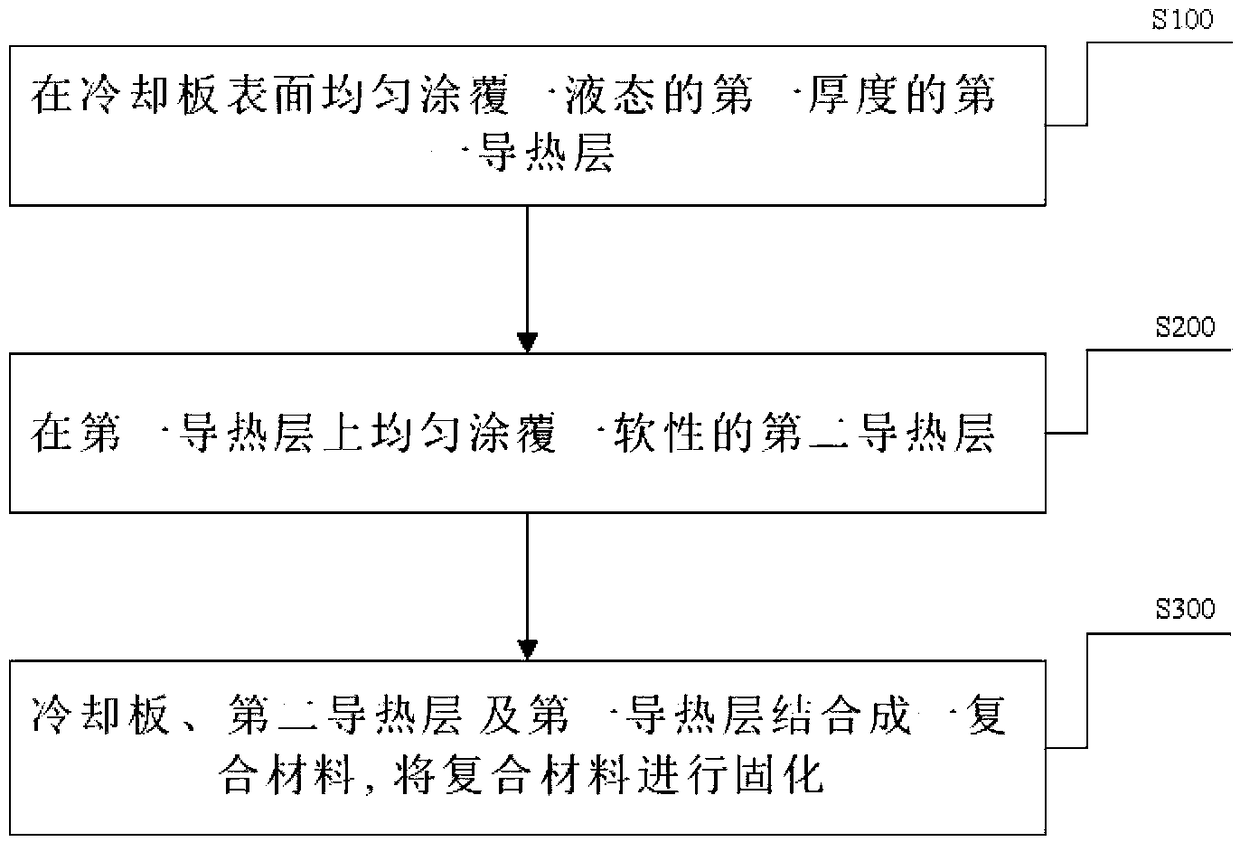

[0056] First coat the surface of the cooling plate with a 0.5mm two-component additive silicone thermal conductive adhesive. The thermal conductive adhesive has the following main characteristics: A / B component mixed viscosity 20Pa.s, hardness after curing is 90, thermal conductivity is 1.6W / m.k, and volume resistivity is 5×10 14 Ω.cm, electric strength 16kV / mm, and aluminum bonding shear strength 3.2MPa.

[0057] The thermally conductive adhesive is coated and molded and cured at 100°C for 10 minutes.

[0058] Then coat the surface of the cured silicone thermal conductive adhesive with a 0.5mm two-component thermally conductive addition molding silicone gel. The thermally conductive silicone gel has the following main characteristics: the viscosity after A / B mixing is 18 Pa.s, and the hardness after curing is 10. The thermal conductivity is 1.6W / mk, and the volume resistivity is 2×10 14 Ω.cm, electric strength 14kV / mm.

[0059] The composite heat dissipation material coated with th...

Embodiment 2

[0061] First, coat the surface of the cooling plate with a 0.2mm one-component addition molding silicone thermal conductive adhesive. The thermal conductive adhesive has the following main characteristics: viscosity 30Pa.s, hardness after curing 92, thermal conductivity 2.5W / mk, volume resistivity 2 ×10 14 Ω.cm, electric strength 18kV / mm, and aluminum bonding shear strength 3.4MPa.

[0062] Then coat the surface of the uncured silicone thermal conductive adhesive with a 0.4mm two-component thermal conductive gel. The thermal conductive gel has the following main characteristics: the viscosity after A / B mixing is 25Pa.s, the hardness after curing is 15, and the thermal conductivity is 2.5 W / mk, volume resistivity 1×10 14 Ω.cm, electric strength 16kV / mm.

[0063] The composite heat dissipation material after coating the thermal gel is cured at a temperature of 150° C. for 20 minutes.

Embodiment 3

[0065] First, print a 0.5mm one-component dealcoholized silicone thermal conductive adhesive on the surface of the cooling plate. The thermal conductive adhesive has the following main characteristics: viscosity 40Pa.s, surface drying time 10 minutes, curing at room temperature, hardness after curing is 88, Thermal conductivity 2.8W / mk, volume resistivity 2×10 14 Ω.cm, electric strength 20kV / mm, and aluminum bonding shear strength 2.8MPa. This one-component dealcoholized silicone thermal conductive adhesive contains glass beads with a diameter of 0.2mm to ensure the thickness of the thermal conductive adhesive layer under subsequent pressure operations> 0.2mm.

[0066] Then, on the surface of the uncured one-component dealcoholized silicone thermal conductive adhesive, a flexible thermal pad with a thickness of 1mm is applied. The flexible thermal pad has the following main characteristics: hardness 10, thermal conductivity 2.6W / mk, volume resistivity 2×10 14 Ω.cm, electric stren...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| dielectric strength | aaaaa | aaaaa |

| dielectric strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com