Solar battery assembly and preparation method thereof

A technology of solar cells and batteries, which is applied in the field of solar cells, can solve the problems of increasing the risk of component battery short circuits and increasing the difficulty of repairing bad battery strings, and achieve the effects of avoiding glare effects, reducing power generation costs, and reducing internal resistance loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

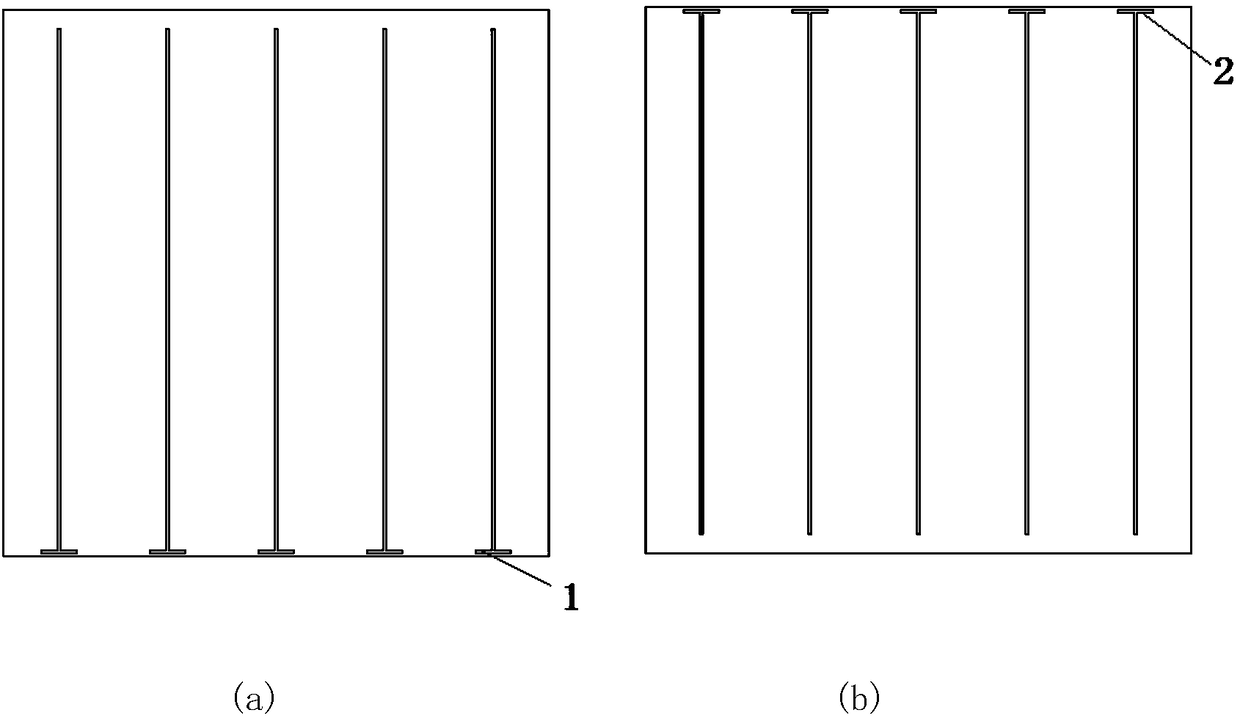

Embodiment 1

[0069] The solar cell assembly provided in this embodiment sequentially includes a cover material, EVA and / or POE, battery strings, EVA and / or POE, and a back sheet material. The battery strings are formed by connecting multiple battery strings, and the battery strings are formed by A plurality of cells are connected in series, and the front electrode and the back electrode of each cell in the plurality of cells are all provided with a conductive material, the conductive material is a metal coating, and one of the adjacent two cells is The front electrode of the cell and the back electrode of another cell are connected in series directly through the metal coating.

[0070] The front electrode of one of the two adjacent battery sheets and the back electrode of the other battery sheet are directly connected in series by heating.

[0071] The temperature during heating is 80-500°C.

[0072] The metal coating can be deposited on the front electrode and / or the back electrode of th...

Embodiment 2

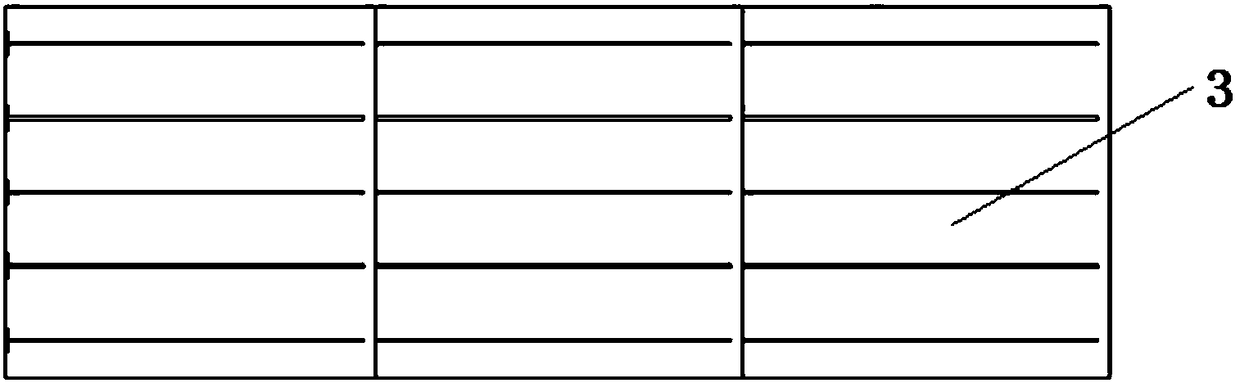

[0081]The solar cell assembly provided in this embodiment sequentially includes a cover material, EVA and / or POE, battery strings, EVA and / or POE, and a back sheet material. The battery strings are formed by connecting multiple battery strings, and the battery strings are formed by A plurality of cells are connected in series, and the front electrode and the back electrode of each cell in the plurality of cells are all provided with a conductive material, the conductive material is a metal coating, and one of the adjacent two cells is The front electrode of the cell and the back electrode of another cell are connected in series directly through the metal coating.

[0082] The front electrode of one of the two adjacent battery sheets and the back electrode of the other battery sheet are directly connected in series by heating.

[0083] The temperature during heating is 80-500°C.

[0084] The metal coating can be deposited on the front electrode and / or the back electrode of the...

Embodiment 3

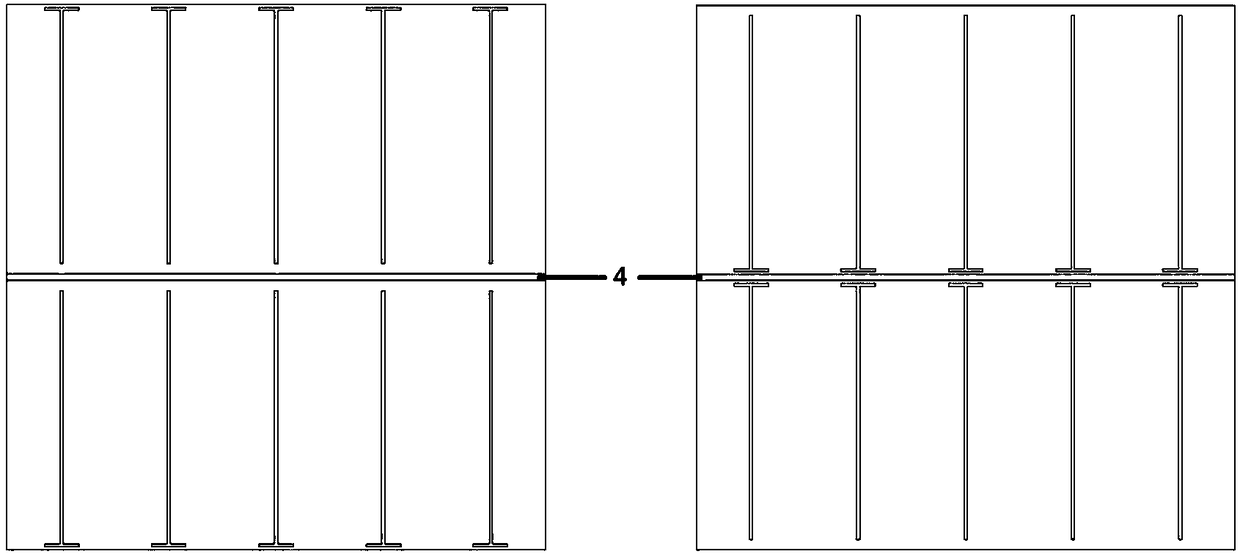

[0094] The solar cell assembly provided in this embodiment sequentially includes a cover material, EVA and / or POE, battery strings, EVA and / or POE, and a back sheet material. The battery strings are formed by connecting multiple battery strings, and the battery strings are formed by A plurality of cells are connected in series, and the front electrode and the back electrode of each cell in the plurality of cells are all provided with a conductive material, the conductive material is a metal coating, and one of the adjacent two cells is The front electrode of the cell and the back electrode of another cell are connected in series directly through the metal coating.

[0095] The front electrode of one of the two adjacent battery sheets and the back electrode of the other battery sheet are directly connected in series by heating the metal coating.

[0096] The temperature during heating is 80-500°C.

[0097] The metal coating can be deposited on the front electrode and / or the ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com