Coal-rock blasting pre-splitting method and device based on packing blasting of liquid explosive in long hole

A technology for liquid explosives and coal and rock, applied in blasting and other directions, can solve the problems such as the difficulty of fixing and pushing the coil in the hole, the high frequency of deep hole blasting rejection, and the increase in the resistance of deep hole charging, etc., to achieve coal and rock blasting. Improve the environment, avoid the problem of rejecting explosions, and achieve the effect of expanding the advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Taking liquid explosive blasting in deep holes in hard coal seams as an example, the hard coal seam fracturing and anti-reflection blasting operations based on liquid explosive sealing injection initiation in deep holes are carried out.

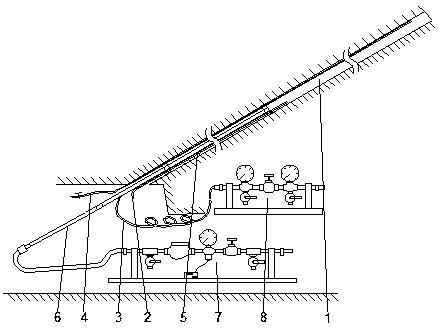

[0020] Such as figure 1 As shown, the coal and rock blasting pre-splitting device based on liquid explosive sealing and detonation in deep holes provided by the present invention includes blasting equipment, hole sealing device 5, grouting pump station 7, and liquid injection pump station 8; Liquid injection pipe 3, exhaust pipe 4 and grouting pipe 6 are provided; liquid injection pipe 3 is connected to liquid injection pump station 7, and grouting pipe 6 is connected to grouting pump station 8; liquid injection pipe 3 and exhaust pipe 4 , grouting pipe 6, grouting pumping station 7 and liquid injection pumping station 8 are all provided with valves; detonating equipment adopts detonating cord 2 and detonator.

[0021] The coal-rock b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com