Inner rib reinforced polyethylene spiral corrugated pipe and joint connecting method thereof

A polyethylene spiral and joint connection technology, which is applied in the direction of pipeline connection arrangement, pipe/pipe joint/pipe fitting, pipe, etc., can solve the problems of reduced service life of pipes, easy delamination and cracking, and potential safety hazards, etc. The effect of structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

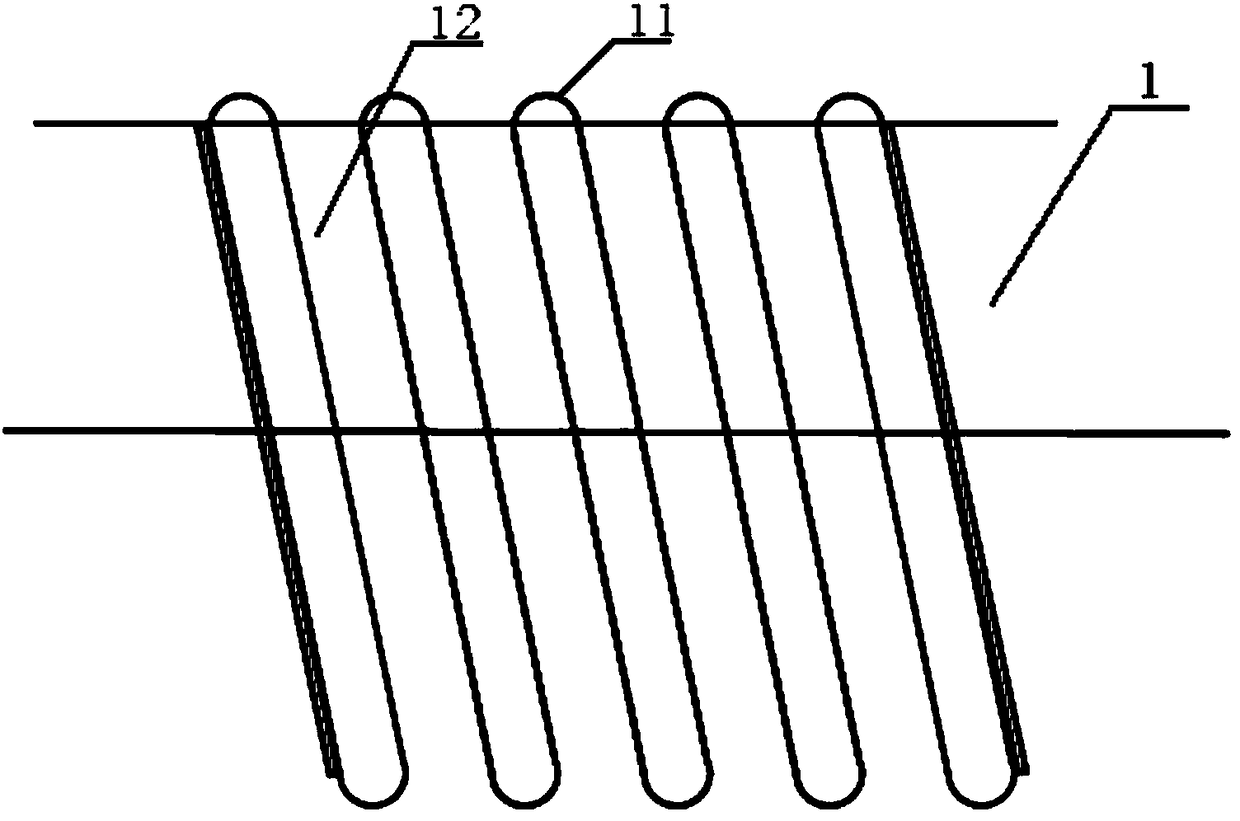

[0053] Such as figure 1 As shown, the internal rib reinforced polyethylene spiral corrugated pipe provided by the present invention includes a corrugated pipe body 1, the corrugated pipe body includes a spiral corrugation 11 and a pipe body 12, and the structure of the spiral corrugation includes an outer layer poly Ethylene layer 21, glass fiber reinforced layer 22 and inner polyethylene layer 23; wherein, the inside of the spiral corrugation 11 is a hollow chamber, and a reinforced internal rib 24 is provided inside it, such as figure 2 and Figure 13 As shown, as a preference, the reinforcing internal rib is one of the following two forms: a strut vertically inside the spiral corrugation, or an X-shaped arrangement in the middle, the two internal ribs intersect each other, and the extending direction Consistent with the direction of the spiral corrugation.

[0054] In this embodiment, the cross-sectional shape of the corrugation is a conventional semicircle.

[0055] As...

Embodiment 2

[0079] The difference from Example 1 is that during the implementation of the joint connection method of the inner rib reinforced polyethylene spiral corrugated pipe, the shrinkage tube is first used for reinforcement, and then the joint is reinforced with a clamp. Such a joint processing technology is repeated in Example 1. On the basis of the structure, the mechanical stability of the structure can be enhanced more effectively.

Embodiment 3

[0081] The difference from the above two embodiments is that an inner rib glass fiber layer is added inside the inner rib, which has a stronger effect.

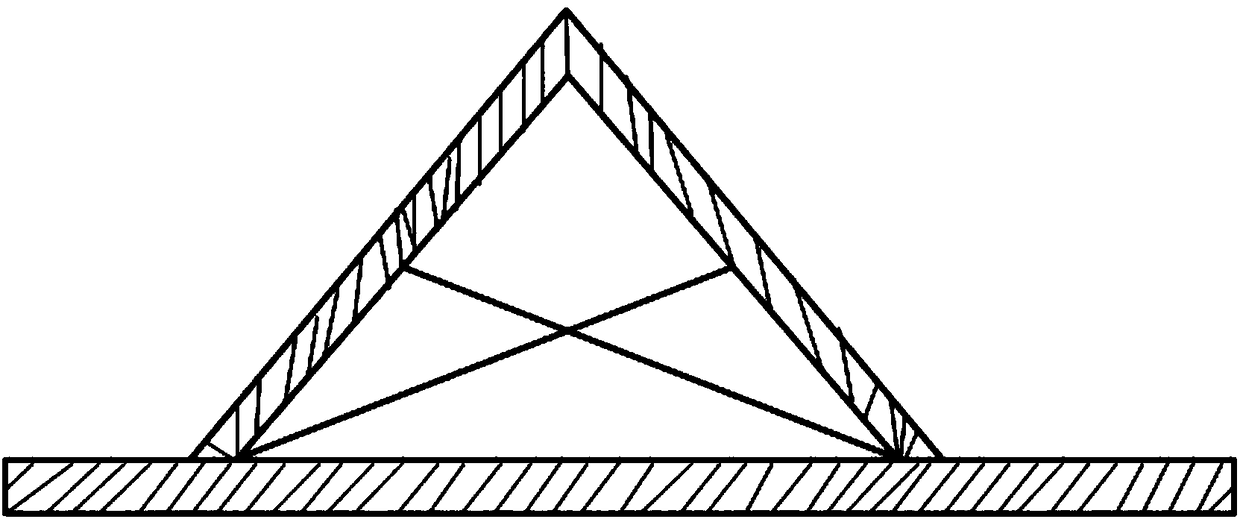

[0082] Such as image 3 , Figure 4 As shown, the corrugated shape has been further optimized, trapezoidal or triangular, and other bellows shapes with simple structure but strong stability can be selected.

[0083] The inner rib reinforced polyethylene spiral corrugated pipe provided by the present invention can also be connected by joints in the following ways:

[0084] Such as Figure 8 The connection of the FRP Huff parts shown is sealed with a rubber sleeve, and the pipes to be connected are connected and fixed through the FRP Huff parts with a spiral.

[0085] This connection method is suitable for pipe diameter DN / ID≤1200mm.

[0086] The connection of the flat port pipe can be connected by conical socket type electrofusion connection, socket type rubber sealing ring connection, etc.

[0087] 1. The socket-type ele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com