A six-degree-of-freedom ultra-low frequency vibration isolation device and its control system based on a zero-stiffness system

A zero-stiffness, degree-of-freedom technology, applied in the field of six-degree-of-freedom vibration isolation devices and their control systems, can solve problems such as few studies, and achieve the effect of low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

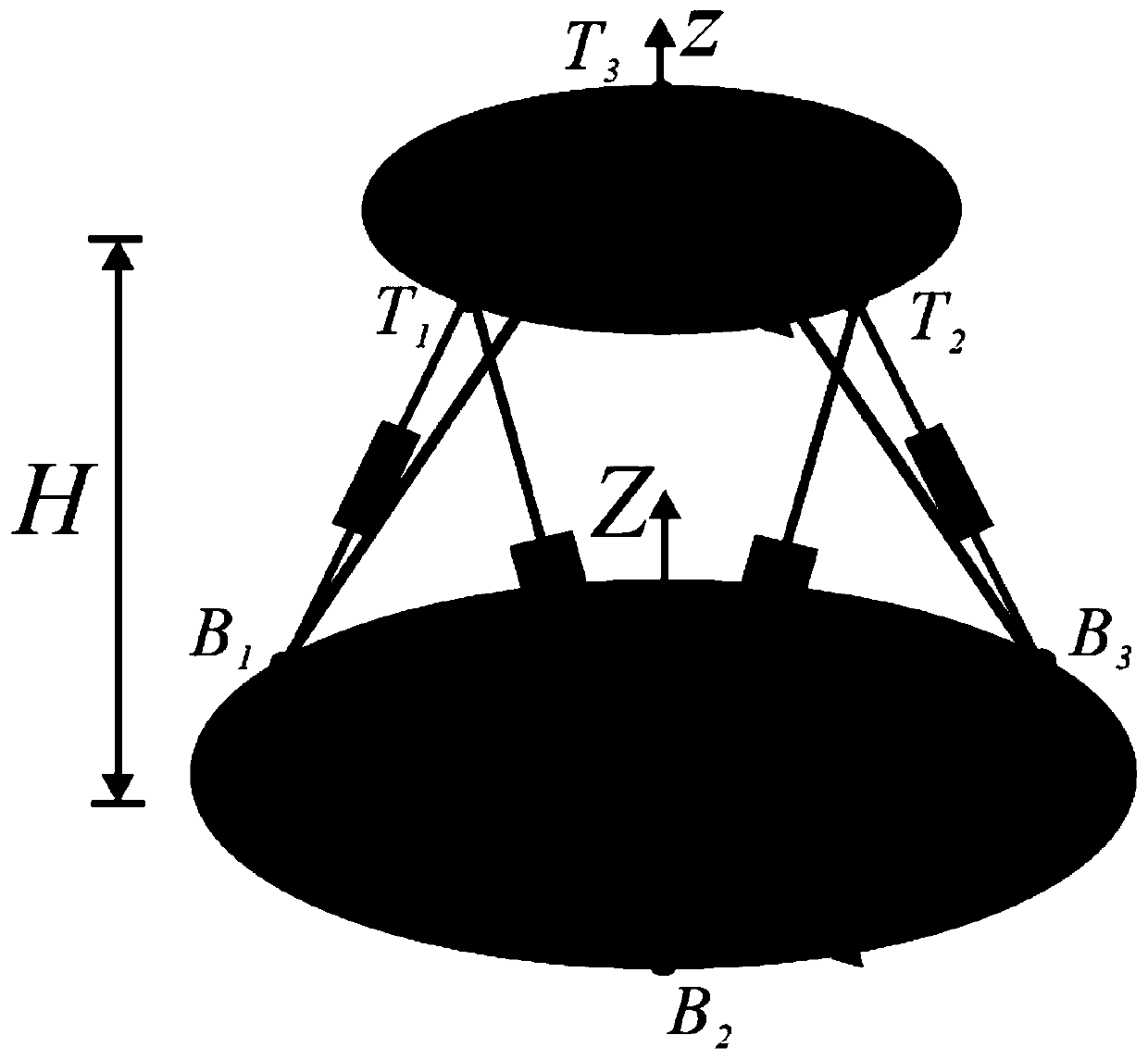

[0059] Specific implementation mode one: as figure 1 , figure 2 and Figure 7 Shown, in conjunction with accompanying drawing, the scheme of the present invention is described in detail:

[0060] A six-degree-of-freedom ultra-low frequency vibration isolation device based on a zero-stiffness system. The zero-stiffness system refers to a system that does not have the ability to resist elastic deformation, has continuous balance, constant potential energy, and neutral stability. Its dynamic equation can be expressed as for

[0061]

[0062] Where X is the displacement vector of the system, ε is the acceleration vector; the zero-stiffness system has the characteristics of zero natural frequency, and can realize low-frequency, ultra-low-frequency, and even low-frequency full-frequency vibration immune vibration isolation performance;

[0063] The configuration of the six-degree-of-freedom ultra-low-frequency vibration isolation device (six-degree-of-freedom ultra-low-frequ...

specific Embodiment approach 2

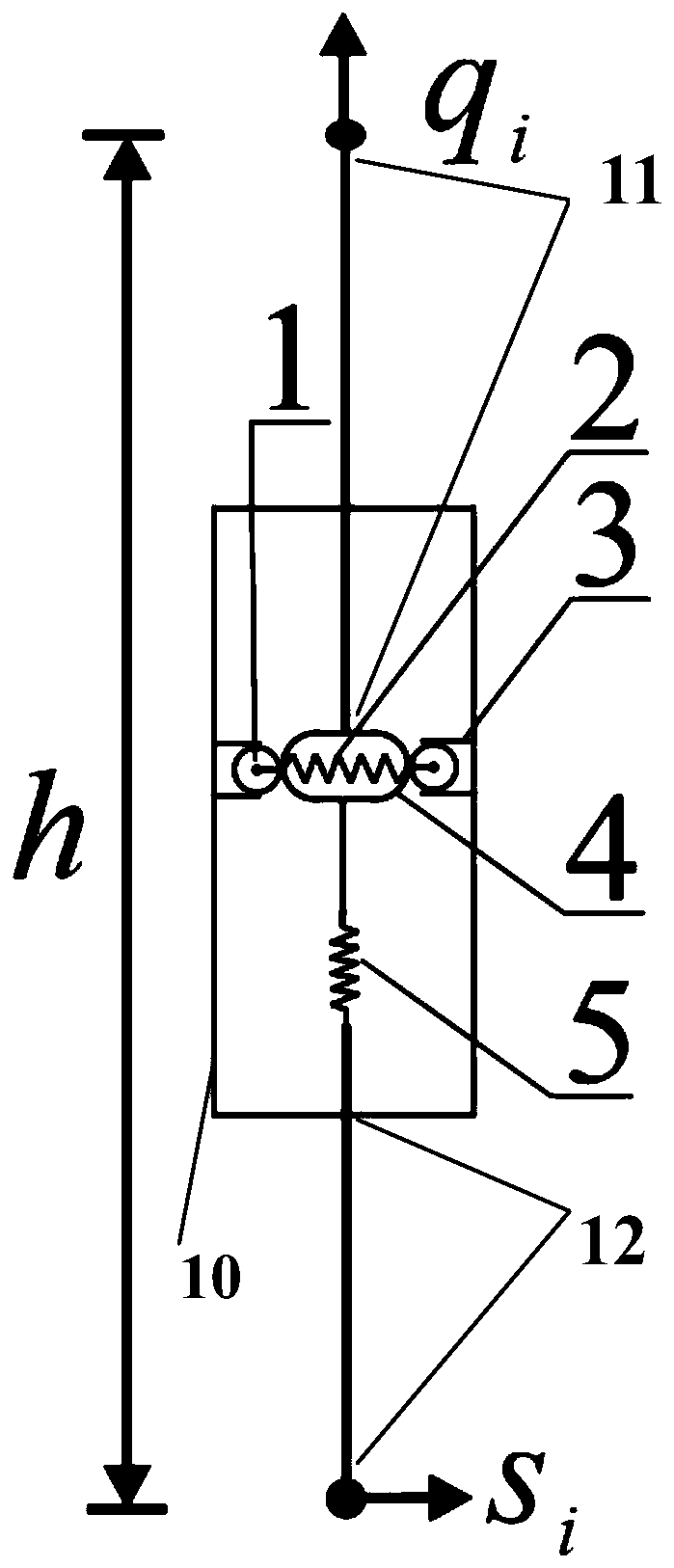

[0097] Specific implementation mode two: as figure 1 and image 3 As shown, other specific implementations of a single vibration isolation module are given:

[0098] The connecting assembly between the springs includes two rollers 1, two guide rails 3, and an intermediate wheel 4, and the horizontal spring includes two horizontal compression springs 2;

[0099] The two guide rails 3 are respectively fixed in the middle of the inner wall of the cylindrical housing 10, and the two are symmetrically distributed. There is a horizontal compression spring 2, the middle wheel 4 is located between the two rollers 1, the upper part of the middle wheel 4 is fixedly connected with the lower end of the upper connecting rod 11, the lower part of the middle wheel 4 is fixedly connected with the upper end of the vertical spring 5, and the middle wheel 4 under the action of the roller 1 located on both sides of it along the q i direction movement; the lower end of the vertical spring 5 is...

specific Embodiment approach 3

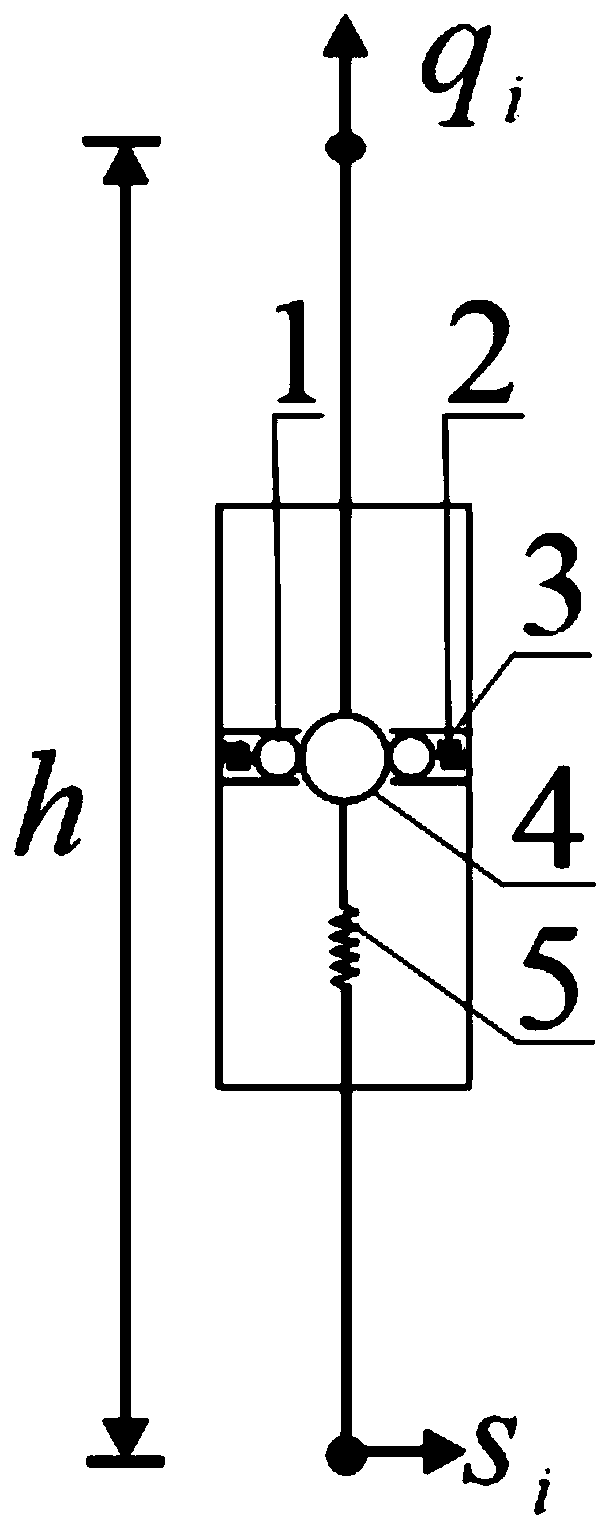

[0106] Specific implementation mode three: as figure 1 and Figure 4 As shown, other specific implementations of a single vibration isolation module are given:

[0107] The connecting assembly between the springs includes two sliders 1, two guide rails 3, and two connecting rods 4, and the horizontal spring includes two horizontal compression springs 2;

[0108] Two guide rails 3 are respectively fixed in the middle of the inner wall of the cylindrical housing 10, and the two are symmetrically distributed. Each slider 1 is placed in the corresponding guide rail 3, and each slider 1 and the inner wall of the corresponding cylindrical housing 10 There is a horizontal compression spring 2 between them, one end of each connecting rod 4 is hinged to the center of the corresponding slider 1, the other ends of the two connecting rods 4 are hinged, and the two connecting rods 4 are located between the two sliders 1,

[0109] The hinged parts of the two connecting rods 4 are connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com