Multi-point jetting device for reinforcing atomization

An injection device, multi-point technology, applied in the fuel valve of the turbine/propulsion device, charging system, turbine/propulsion fuel delivery system, etc., can solve the problems of low fuel supply pressure, limited size, complex structure, etc. The effect of improving combustion efficiency and improving atomization ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and specific implementation examples.

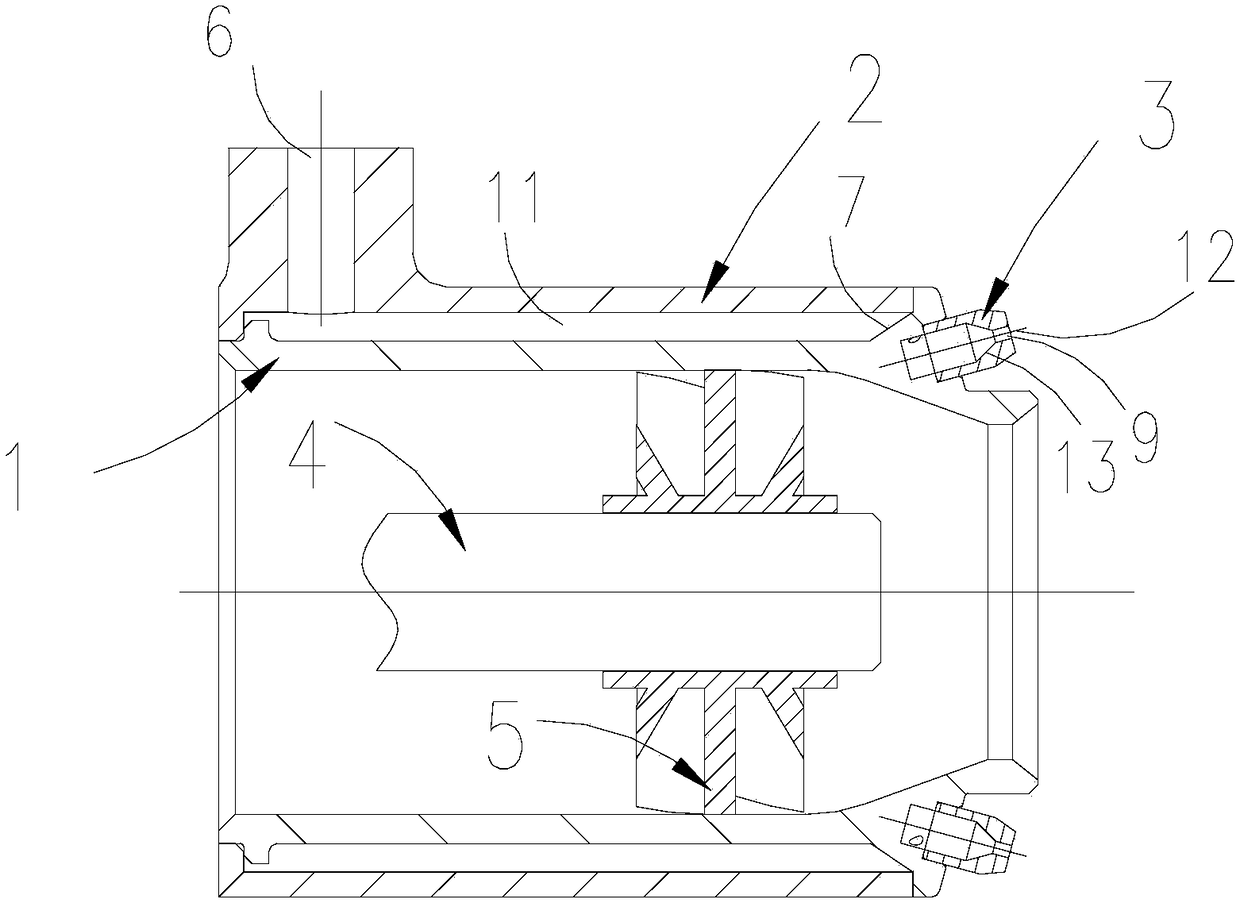

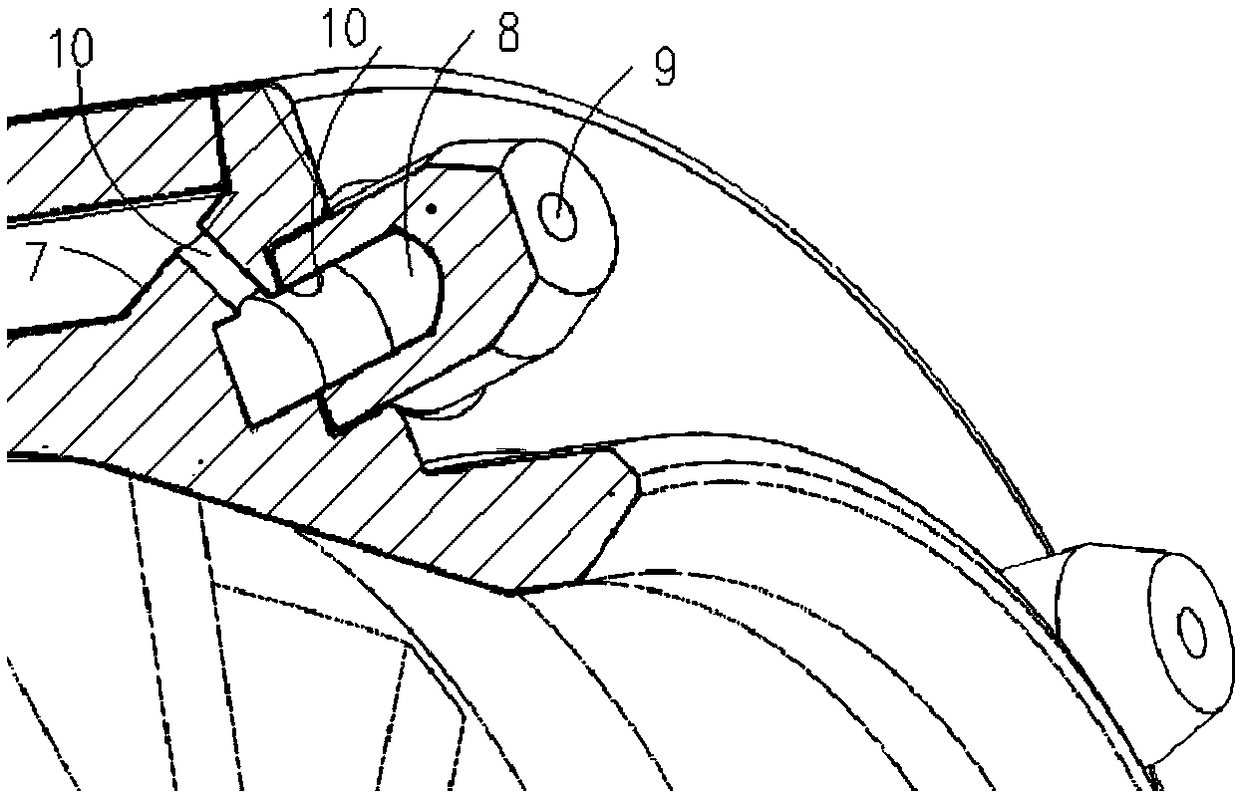

[0019] refer to figure 1 , figure 2 , a multi-point injection device for enhancing atomization, the device includes a throat 1, a shell 2, a main nozzle 3, a secondary nozzle 4, and a cyclone 5. An eccentric bore 10 is arranged on the conical surface 7 of the throat 1 .

[0020] Further, it is characterized in that the number of main nozzles 3 is 6-12.

[0021] Further, it is characterized in that the eccentric holes 10 deviate from the central axis 12 of the main nozzle 3 by a certain distance, and the eccentric holes 10 are distributed along the circumferential direction of the central axis 12, and the number is 1-2.

[0022] Further, it is characterized in that the main nozzle 3 is provided with a swirl chamber 8 with a diameter of 2-3 mm, and transitions to the nozzle hole 9 along the converging cone surface 13, and the di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com