Seepage drainage device with replaceable filter core in tailings pond and filter core replacement method

A replacement method and filter element technology, which is applied in soil drainage, construction, agriculture, etc., can solve the problems of long length of seepage pipe, difficulty in replacing the filter element of the seepage pipe in situ, and inability to lay filter material, etc., so as to achieve the goal of compression Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

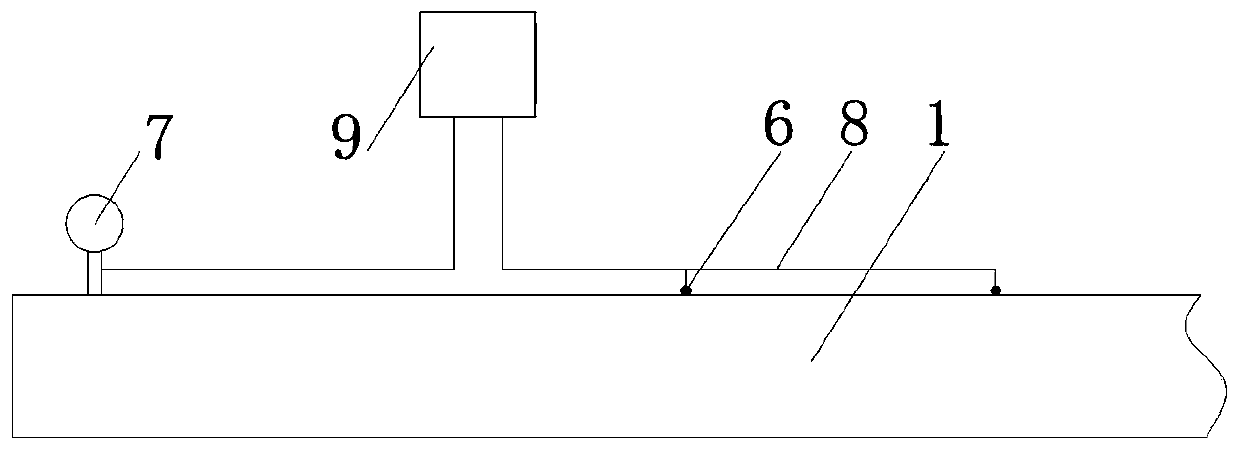

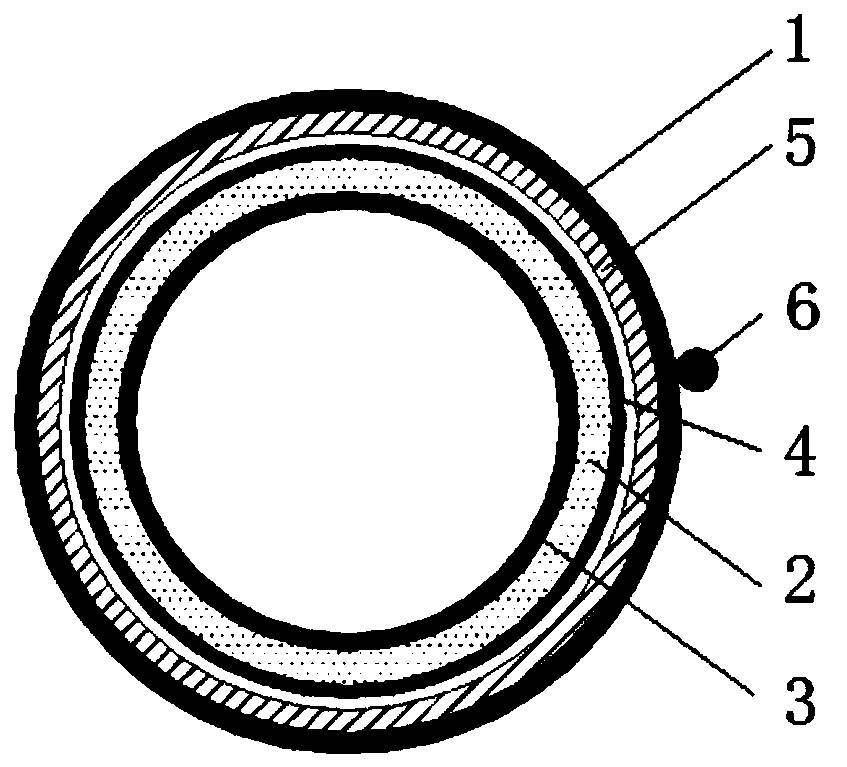

[0024] Such as figure 1 , figure 2 As shown, the seepage drainage device includes a seepage drainage pipe and a clogging monitoring system connected to the seepage drainage pipe, wherein the seepage drainage pipe includes an outer floral tube 1, a filter element 2 and an inner floral tube 3, and the clogging monitoring system includes a seepage pressure meter 6, flow meter 7 and processor 9.

[0025] The outer flower tube 1 is buried in the pre-drilled hole and will not be pulled out, and is in direct contact with the tailings, so as to support the external tailings and form the inner space; the outer flower tube 1 is made of anti-corrosion UPVC Material, the flower tube diameter is 56-90mm, the opening diameter is 12-15mm, the opening rate is 13%-15%, and the water guide section at the end of the flower tube does not need to be drilled. The outer flower tube is made in sections, and the sections are connected by pipe hoops.

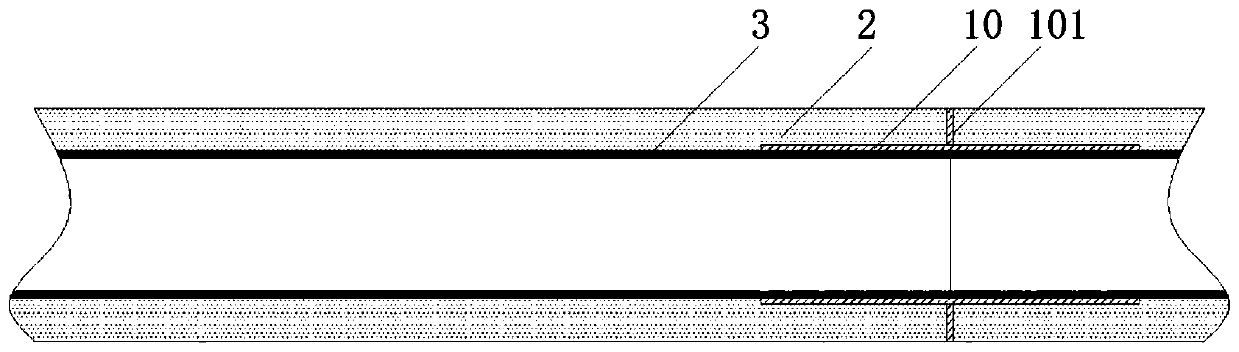

[0026] Such as image 3 As shown, the filter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com