Thermoelectric heat pipe combined clothes dryer

The technology of a compound type and clothes dryer is applied in the field of clothes dryers, which can solve the problems of ordinary heat pump clothes dryers occupying a large room space, affecting the normal living environment of users, and large volume of the heat pump device, so as to shorten the drying time. , The effect of occupying a small space and reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

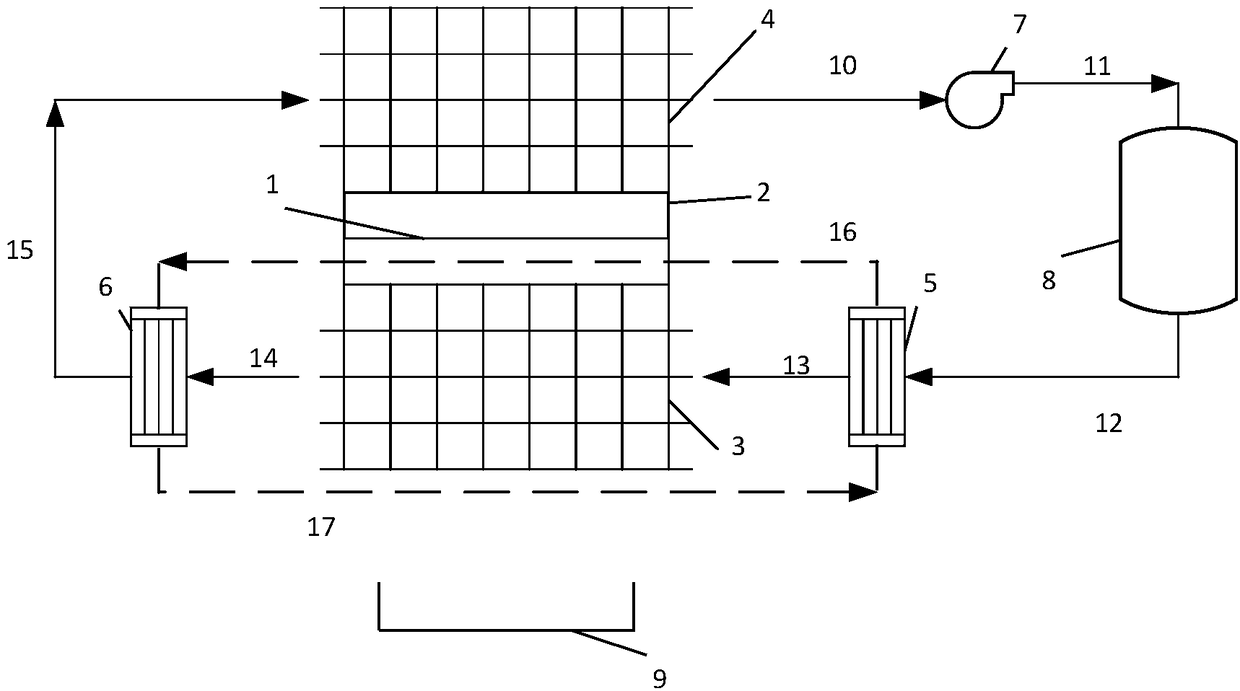

[0042] A thermoelectric heat pipe composite clothes dryer, the structure of which is as follows: figure 1 As shown, it includes a thermoelectric cooler, a precooling heat exchanger 5 , a reheating heat exchanger 6 , a blower fan 7 and a clothes dryer 8 .

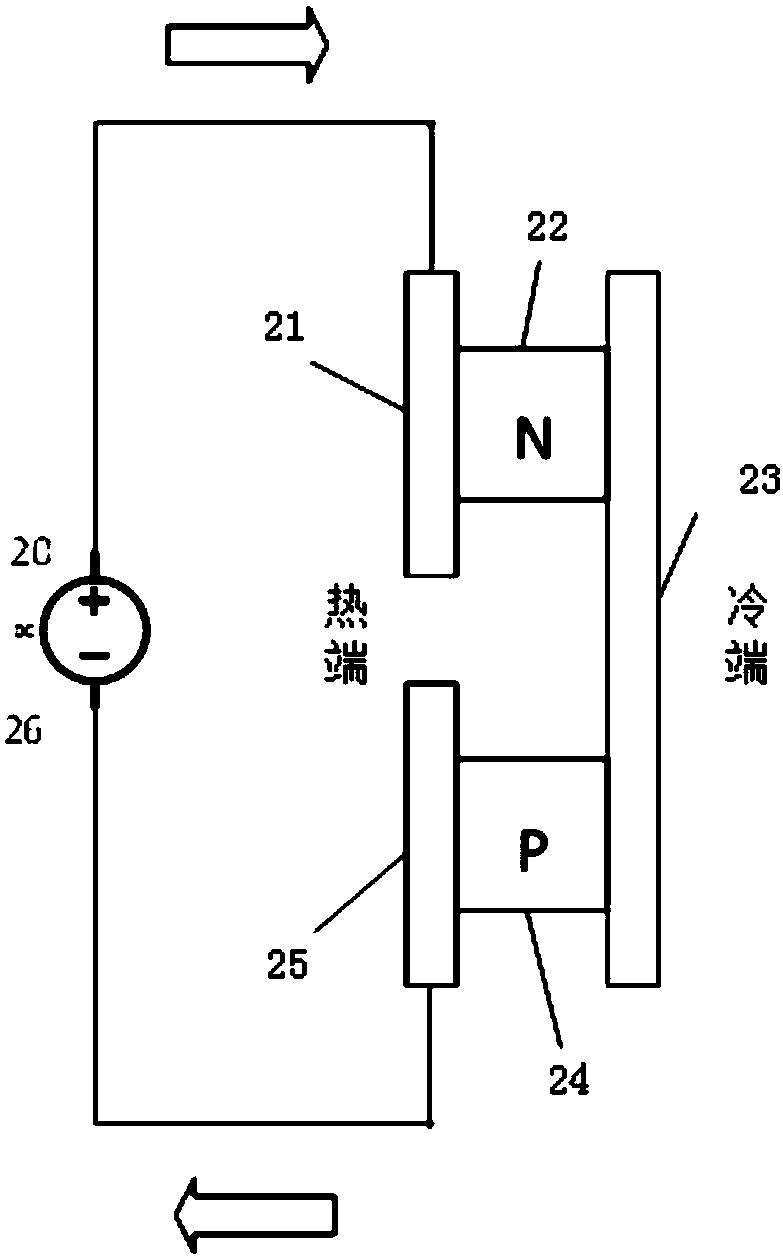

[0043] The thermoelectric cooler contains a thermoelectric refrigeration circuit, and includes a cold end 1 of the thermoelectric cooler and a hot end 2 of the thermoelectric cooler. The cold end 1 of the thermoelectric cooler is provided with a heat absorbing sheet 3 at the cold end of the thermoelectric cooler. The thermoelectric cooler The cold end heat sink 3 has an air channel, and the thermoelectric cooler hot end heat sink 4 is provided at the thermoelectric cooler hot end 2, and the thermoelectric cooler hot end heat sink 4 has an air channel.

[0044] The precooling heat exchanger 5 includes refrigerant passages and air passages, and the reheat heat exchanger 6 includes refrigerant passages and air passages.

[004...

Embodiment 2

[0055] refer to image 3 , the difference from Embodiment 1 is that in this embodiment, the loop heat pipe is driven by a refrigerant pump, the gravity-driven loop heat pipe is a closed cycle, and the gravity-driven cycle of a single closed cycle In the loop heat pipe, the refrigerant channel of the pre-cooling heat exchanger 5, the refrigerant connecting pipe 16, the refrigerant channel of the reheating heat exchanger 6, the refrigerant connecting pipe 17, the refrigerant pump 19, the refrigeration The refrigerant connecting pipe 18 is connected end to end, and the refrigerant passes through the refrigerant connecting pipe through the refrigerant channel of the precooling heat exchanger, the refrigerant pump and the refrigerant channel of the reheating heat exchanger in sequence.

[0056] Compared with Embodiment 1, only the driving mode of the loop heat pipe is changed from gravity to refrigerant pump. In the loop heat pipe, the liquid refrigerant returns to the refrigerant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com