A kind of high magnetostriction coefficient Fe-ga based thin strip and its preparation method

A technology of stretching and fe-ga, which is applied in the field of high magnetostrictive coefficient Fe-Ga-based thin ribbon and its preparation, which can solve the problems of low magnetostrictive performance, high equipment precision requirements, and reduced magnetostrictive coefficient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0098] High magnetostriction coefficient Fe-Ga base thin strip, its composition contains by weight percentage: C: 0.03%, Al: 0.03%, Nb: 0.25%, Cu: 0.5%, Mn: 0.08%, S: 0.02% , Sn: 0.06%, Mo: 0.5%, the balance is Fe and other unavoidable impurities, and the Ga content is shown in Table 1.

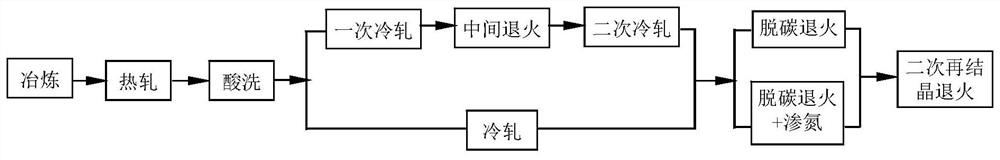

[0099] The preparation method of the above-mentioned high magnetostriction coefficient Fe-Ga base thin strip comprises the following steps:

[0100] Step 1, smelting:

[0101] According to the set composition of the thin strip in Table 1, it is cast after smelting at 1440-1600°C;

[0102] Step 2, hot rolling:

[0103] (1) Heat the billet to 1100-1280°C and keep it warm;

[0104] (2) hot-rolling the billet after heating and heat preservation, the rolling start temperature is 1150-1200 ℃, and obtain a hot-rolled plate with a thickness of 2.5 mm after cooling;

[0105] Step 3, pickling and cold rolling:

[0106] (1) pickling the hot-rolled plate;

[0107] (2) The hot-rolled plate after pic...

Embodiment 2

[0119] High magnetostriction coefficient Fe-Ga base thin strip, its composition and weight percentage content is Ga: 22.3%, other composition is shown in Table 2, the balance is Fe and other unavoidable impurities.

[0120] The preparation method of the above-mentioned high magnetostriction coefficient Fe-Ga base thin strip comprises the following steps:

[0121] Step 1, smelting:

[0122] According to the set composition of the thin strip in Table 2, it is cast after smelting at 1440-1600°C;

[0123] Step 2, hot rolling:

[0124] (1) Heat the billet to 1100-1250°C and keep it warm;

[0125] (2) hot-rolling the billet after heating and heat preservation, the rolling start temperature is 1100-1200°C, and obtain a hot-rolled plate with a thickness of 2.3 mm after cooling;

[0126] Step 3, pickling and cold rolling:

[0127] (1) pickling the hot-rolled plate;

[0128] (2) The hot-rolled plate after pickling is carried out cold-rolled, adopts the cold-rolled thin strip of 0.2...

Embodiment 3

[0142] High magnetostriction coefficient Fe-Ga base thin strip, its composition contains by weight percentage: Ga: 20.4%, C: 0.05%, Nb: 0.1%, Cu: 0.2%, Mn: 0.08%, S: 0.015% ,, Mo: 0.05%, Tb: 0.3, the balance is Fe and other unavoidable impurities, and the Al content varies as shown in Table 3.

[0143] The preparation method of the above-mentioned high magnetostriction coefficient Fe-Ga base thin strip comprises the following steps:

[0144] Step 1, smelting:

[0145] According to the set composition of the thin strip in Table 3, it is cast after smelting at 1440-1600°C;

[0146] Step 2, hot rolling:

[0147] (1) Heat the billet to 1100-1280°C and keep it warm;

[0148] (2) hot-rolling the slab after heating and heat preservation, the rolling start temperature is 1150°C, and obtain a 4mm thick hot-rolled plate after cooling;

[0149] Step 3, pickling and cold rolling:

[0150] (1) hot rolling is carried out pickling to remove scale;

[0151] (2) The hot-rolled sheet is r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com