Fluorescent nano material for detecting PETN (Pentaerythritol Nitrate) and application of fluorescent nano material

A technology of pentaerythritol tetranitrate and fluorescent nanomaterials, which is applied in the field of fluorescent nanomaterials, can solve the problems of limiting response rate and sensing performance, poor gas permeability of sensing films, fluorescence quenching of fluorescent molecules, etc., and achieves good application prospects. , The preparation method is simple, fast, and easy to separate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1: The present invention is used for the preparation method of the fluorescent nanomaterial of detecting pentaerythritol tetranitrate

[0035] (1) Synthesis of nano-silica microspheres

[0036] Take 50mL of ethanol, 5.6g of ammonia water (30%) and 4.5g of water in a 250mL flask, dissolve 2.5g of tetraethoxysilane in 5mL of ethanol, quickly add to the above solution, and stir vigorously at 40°C for 5 minutes. Dissolve 2.4 g of vinyltriethoxysilane (the molar ratio of tetraethoxysilane (TEOS) to vinyltriethoxysilane (VTEOS) is 1:1) in 5 mL of ethanol, and add it dropwise to the above solution . After the addition, continue to stir and heat vigorously for 30 minutes, then centrifuge the mixed solution at a rate of 3500 rpm, wash with ethanol and water several times, and dry to obtain 3.2 g of white powdery nano-silica microspheres with a particle size of 200- 300nm.

[0037] (2) Synthesis of fluorene-substituted nano-silica microspheres

[0038]Weigh 450mg o...

Embodiment 2

[0044] The sensing thin layer based on compound 1 was prepared on the quartz substrate by solid phase transfer technique. The preparation method of the sensing thin-layer device comprises the following steps: dispersing the fluorene-substituted nano-silicon oxide microspheres in ethanol at a concentration of 3 mg / mL, and slowly dropping the dispersion into distilled water drop by drop after ultrasonic oscillation, A thin layer of nano-microspheres is formed on the surface of the solution, and the quartz plate substrate is pulled out of the liquid surface from the ethanol-water dispersion at a fixed angle, so that the thin layer of nano-microspheres evenly covers the surface of the quartz plate to form a thin sensing layer. Place in a vacuum oven to drain the residual liquid.

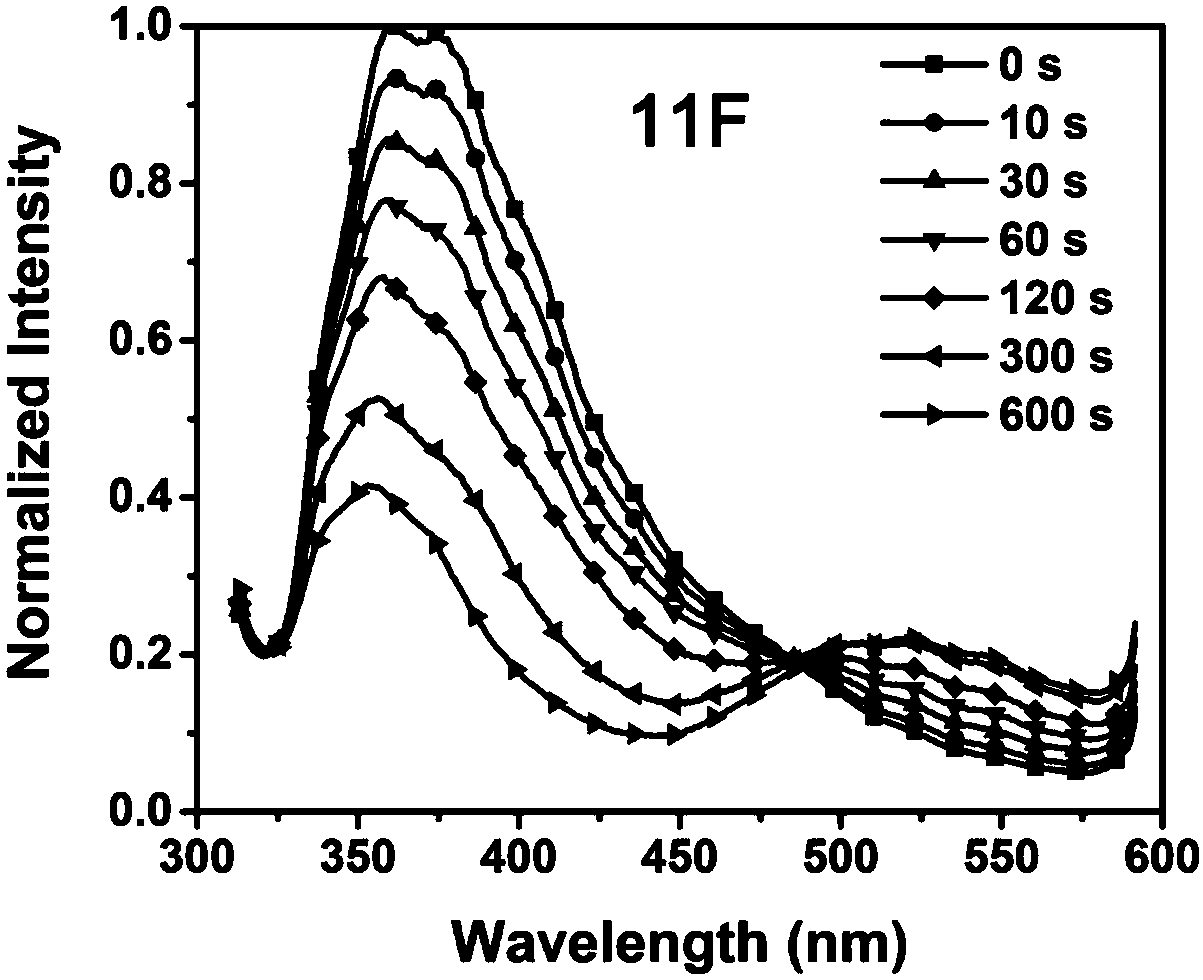

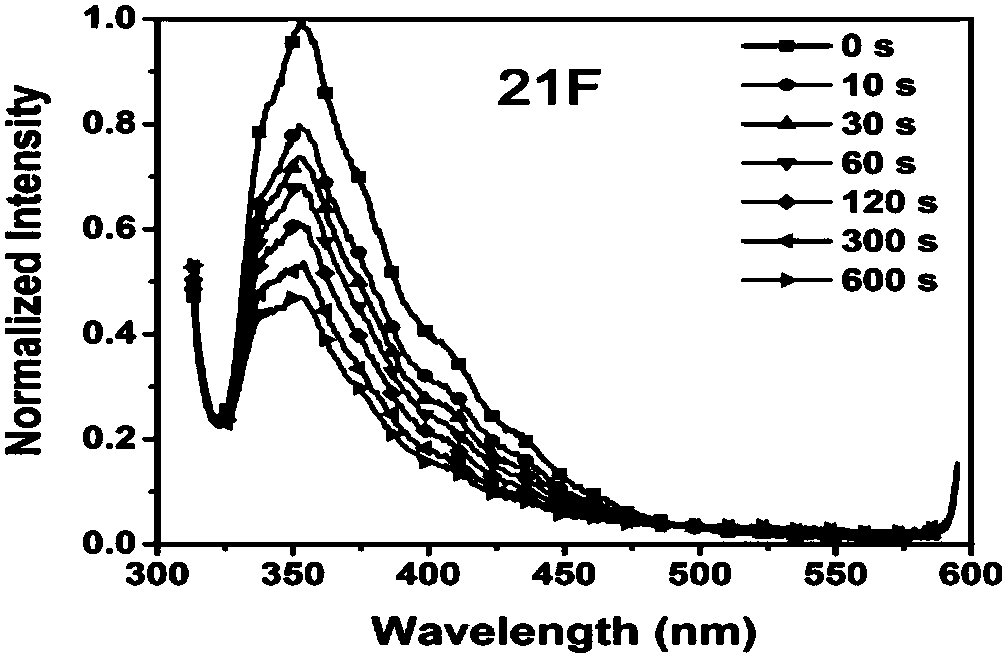

[0045] The fluorescence spectrum and photostability of the sensing thin-layer device can be tested by an ultraviolet-visible fluorescence spectrometer. When testing the sensing performance, put a little...

Embodiment 3

[0051] A solid phase transfer technique similar to that of Example 2 was used to prepare a sensing thin layer based on Compound 1 on a quartz plate substrate. The dispersion concentration of the microspheres in ethanol was 3 mg / mL, which was dropped into distilled water to obtain a thin layer of nano-microspheres. Cover the surface by pulling the quartz sheet and allow to dry. When testing the sensing performance, place the blank, trinitrotoluene (TNT), RDX, and trinitrophenol (PA) samples at the bottom of four sealed quartz cuvettes, and cover them with absorbent cotton Sealed for several hours before use. Put the prepared sensing thin-layer device into the cuvette and seal it, and use the ultraviolet-visible fluorescence spectrometer to quickly measure the change of its fluorescence emission curve, and compare the influence of four analytes on the fluorescence emission peak intensity at 355nm. like Figure 4 As shown, after 10 minutes of exposure to different analytes, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com