A kind of production technology of nano-silver wire transparent conductive film

A technology of transparent conductive film and nano-silver wire, applied in conductive coatings, coatings, etc., can solve the problem of few patents of nano-silver wire transparent conductive film, save manpower and material resources, reduce haze, and improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

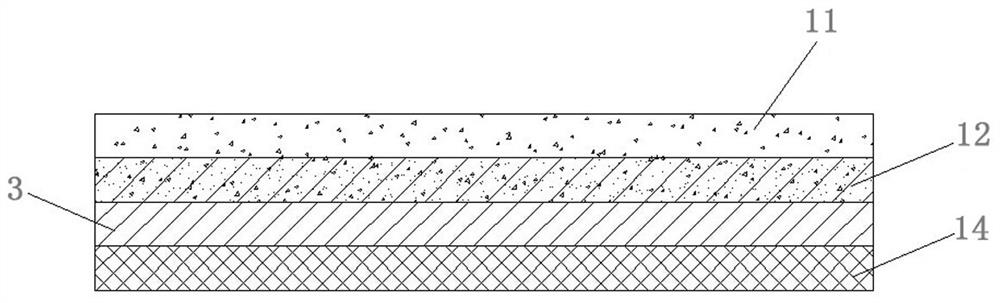

[0034] A kind of production method of nano-silver wire transparent conductive film, comprises the following steps:

[0035](1) Substrate preparation: apply the prepared hardened coating solution on the PET film base. In terms of weight percentage, the main components of the hardened layer coating solution are: 7% pure acrylic resin, 11% ten-functional polyurethane resin %, 20% of difunctional polyurethane resin, 6% of lauric acid acrylate, 6% of methyl benzoylformate, 50% of methyl ethyl ketone; the film base is hardened; the hardness of the non-nano silver wire coated surface of the PET film base is More than 1H; light transmittance 92%, haze ≤ 0.7%, thickness of PET film base is 100μm, dyne value of coating surface ≥ 50, no cracks on the surface after hot pressing at 190°C and 5Mpa for 30 seconds; the prepared The PET film base is placed on the supply rack;

[0036] (2) Coating nano-silver wire coating solution and protective glue coating solution: the configured nano-silve...

Embodiment 2

[0044] The main steps and methods of this embodiment are the same as those of Example 1, and will not be repeated here. The difference is that 1. the composition of the hardening layer coating solution is: 5% pure acrylic resin, 13% ten-functional polyurethane resin, and two Functional group polyurethane resin 26%, tetrahydrofurfuryl acrylate 6%, phenyl bis(2,4,6-trimethylbenzoyl) phosphine oxide 3%, ethylene glycol 47%; ②Nano silver wire coating Coating amount is 10mL / m 2 .

[0045] The performance index of the transparent conductive film finished product that the present invention produces is as shown in table 2 below:

[0046] The performance index of the transparent conductive film finished product that table 2 embodiment of the present invention 2 produces

[0047]

Embodiment 3

[0049] The main steps and methods of this embodiment are the same as those of Example 1, and will not be repeated here. The difference is that 1. the composition of the hardening layer coating solution is: 5% pure acrylic resin, 18% ten-functional polyurethane resin, and two Functional group polyurethane resin 23%, tripropylene glycol diacrylate 5%, 1-hydroxy-cyclohexyl-phenyl ketone 3%, acetone 46%; ②The coating amount of nano-silver wire coating is 50mL / m 2 .

[0050] The performance index of the transparent conductive film finished product that the present invention produces is as shown in table 3 below:

[0051] The performance index of the transparent conductive film finished product that table 3 embodiment of the present invention 3 produces

[0052]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com