Strong bending polyester resin for mixed powder coating and preparation method thereof

A powder coating and polyester resin technology, applied in the field of polyester resin and strong bending polyester resin, can solve the problems of many customer complaints, improve flexibility, improve conversion rate, promote linearization and branching effect of reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

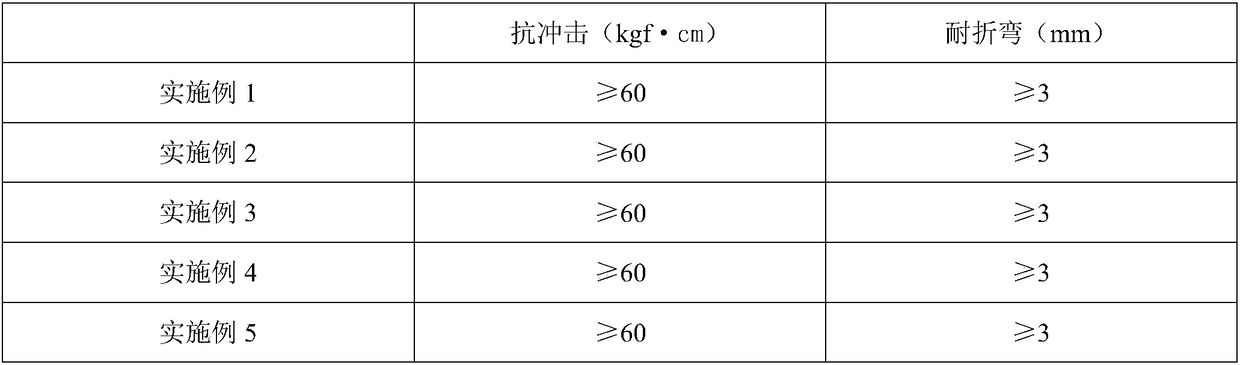

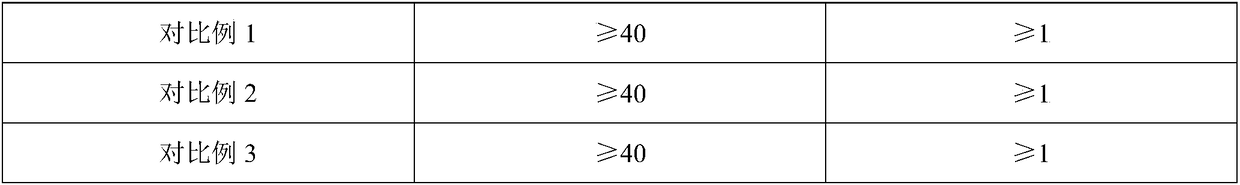

Examples

Embodiment 1

[0034] A preparation method of strong bending polyester resin for hybrid powder coating, the specific steps are as follows:

[0035] (1) Add 2-ethyl-2-methyl-1,3-propanediol, 1,4-cyclohexanedimethanol, triethylene glycol, the first part Azelaic acid, branching agent and esterification catalyst, continue to pass nitrogen, heat up to 140°C, stir for 30 minutes, then raise the temperature to 230°C at a heating rate of 8°C / hour, and then raise the temperature at a heating rate of 2°C / hour to 250°C, stirring and reacting for 2 hours;

[0036] (2) Cool down to 200°C, add trimellitic anhydride and the second part of azelaic acid, then heat up to 260°C, and stir for 30 minutes;

[0037] (3) Cool down to 180°C, add curing accelerator, continue to stir for 1 hour, remove most of the water-carrying agent under reduced pressure for the first time, then add water, remove all solvents under reduced pressure for the second time, and solidify after natural cooling, Instantly.

[0038] Amon...

Embodiment 2

[0048] A preparation method of strong bending polyester resin for hybrid powder coating, the specific steps are as follows:

[0049] (1) Add 2-ethyl-2-methyl-1,3-propanediol, 1,4-cyclohexanedimethanol, triethylene glycol, the first part Azelaic acid, branching agent and esterification catalyst, continue to pass nitrogen, heat up to 150°C, stir for 40 minutes, then raise the temperature to 235°C at a heating rate of 10°C / hour, and then raise the temperature at a heating rate of 3°C / hour to 255°C, stirring and reacting for 3 hours;

[0050] (2) Cool down to 210°C, add trimellitic anhydride and the second part of azelaic acid, then heat up to 265°C, and stir for 40 minutes;

[0051] (3) Cool down to 190°C, add a curing accelerator, continue to stir for 2 hours, remove most of the water-carrying agent under reduced pressure for the first time, then add water, remove all solvents under reduced pressure for the second time, and solidify after natural cooling. Instantly.

[0052] ...

Embodiment 3

[0062] A preparation method of strong bending polyester resin for hybrid powder coating, the specific steps are as follows:

[0063] (1) Add 2-ethyl-2-methyl-1,3-propanediol, 1,4-cyclohexanedimethanol, triethylene glycol, the first part Azelaic acid, branching agent and esterification catalyst, continue to pass nitrogen, heat up to 140°C, stir for 40 minutes, then raise the temperature to 235°C at a heating rate of 8°C / hour, and then raise the temperature at a heating rate of 2°C / hour to 255°C, stirring and reacting for 2 hours;

[0064] (2) Cool down to 210°C, add trimellitic anhydride and the second part of azelaic acid, then heat up to 260°C, and stir for 40 minutes;

[0065] (3) Cool down to 180°C, add curing accelerator, continue to stir for 2 hours, remove most of the water-carrying agent under reduced pressure for the first time, then add water, remove all solvents under reduced pressure for the second time, and solidify after natural cooling, Instantly.

[0066] Amo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com