A kind of hydrophilic soft sponge and its preparation method and application

A hydrophilic and soft technology, applied in applications, absorbent pads, clothing, etc., can solve the problems of slow absorption, insufficient softness and resilience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

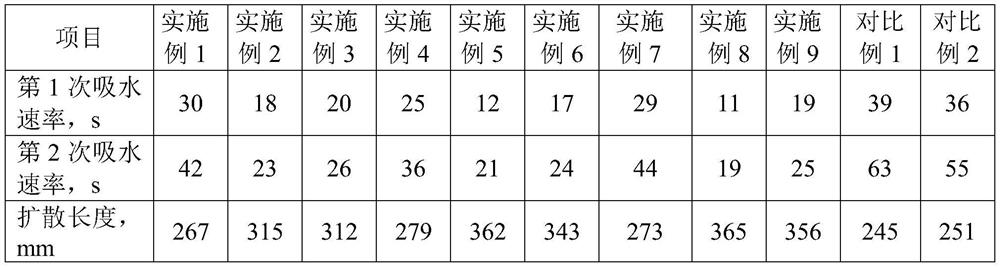

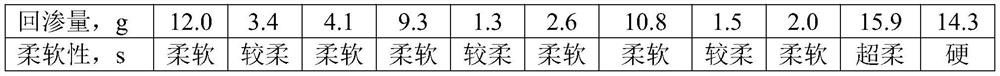

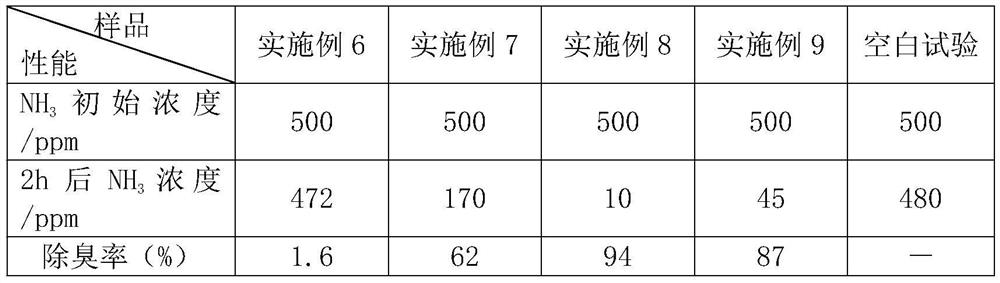

Examples

Embodiment 1

[0034] The hydrophilic soft sponge in this embodiment is made of the following raw materials in parts by weight: 10.9 parts of DEP-505S, 9.1 parts of general-purpose polyether polyol, 10 parts of toluene diisocyanate, 5 parts of dichloromethane, 0.5 parts of silicone oil, 0.1 part of methyl ethanolamine, 0.1 part of stannous octoate, 5 parts of cellulose, 1 part of superabsorbent resin, and 1.5 parts of deionized water. Wherein, the superabsorbent resin is a polyacrylic superabsorbent resin with a particle diameter of 200-410 μm.

[0035] The preparation method of the present embodiment hydrophilic soft sponge comprises the steps:

[0036] S1. Weigh each raw material in parts by weight.

[0037] S2. Put DEP-505S, general-purpose polyether polyol, cellulose, superabsorbent resin and deionized water into the storage tank, set a constant material temperature of 20-23°C, and continuously stir at a speed of 15r / min for 60min. Material A is obtained.

[0038] S3. Mix toluene diis...

Embodiment 2

[0042] The hydrophilic soft sponge in this example is made of the following raw materials in parts by weight: 36 parts of DEP-505S, 24 parts of general-purpose polyether polyol, 40 parts of toluene diisocyanate, 15 parts of methylene chloride, and 1.5 parts of silicone oil , 0.5 parts of dimethylethanolamine, 0.5 parts of stannous octoate, 15 parts of cellulose, 20 parts of superabsorbent resin, and 3 parts of deionized water. Wherein, the superabsorbent resin is a polyacrylic superabsorbent resin with a particle diameter of 200-410 μm.

[0043] The preparation method of the present embodiment hydrophilic soft sponge comprises the steps:

[0044] S1. Weigh each raw material in parts by weight.

[0045] S2. Put DEP-505S, general-purpose polyether polyol, cellulose, superabsorbent resin and deionized water into the storage tank, set a constant material temperature of 20-23°C, and continuously stir at a speed of 120r / min for 10min. Material A is obtained.

[0046] S3. Mix tolu...

Embodiment 3

[0050] The hydrophilic soft sponge in this example is made of the following raw materials in parts by weight: 27 parts of DEP-505S, 15 parts of general-purpose polyether polyol, 20 parts of toluene diisocyanate, 10 parts of methylene chloride, and 1.0 part of silicone oil , 0.8 parts of dimethylethanolamine, 0.2 parts of stannous octoate, 10 parts of cellulose, 10 parts of superabsorbent resin, and 2 parts of deionized water. Wherein, the superabsorbent resin is a polyacrylic superabsorbent resin with a particle diameter of 200-410 μm.

[0051] The preparation method of the present embodiment hydrophilic soft sponge comprises the steps:

[0052] S1. Weigh each raw material in parts by weight.

[0053] S2. Put DEP-505S, general-purpose polyether polyol, cellulose, superabsorbent resin and deionized water into the storage tank, set a constant material temperature of 20-23°C, and continuously stir at a speed of 50r / min for 30min. Material A is obtained.

[0054] S3. Mix toluen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com