Alkali activated gelling material and preparation method thereof

A cementitious material, alkali-activated technology, applied in cement production, etc., can solve problems such as blooming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

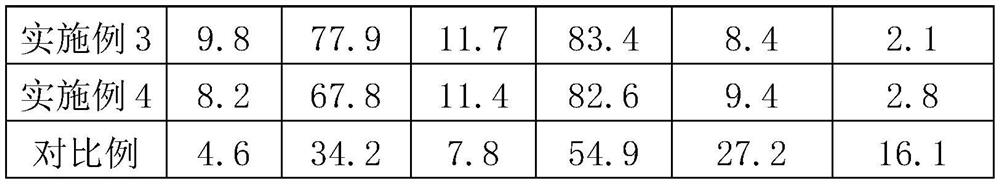

Examples

preparation example Construction

[0032] An embodiment of the present invention proposes a method for preparing an alkali-activated gelling material. The raw materials include powder raw materials, an activator and a nano-component, and the activator is a water glass solution and / or a sodium hydroxide solution. The mass ratio of water and powder raw materials in the agent is the preset water-cement ratio; it includes:

[0033] 1) Mix the nano-components with the activator, use mechanical stirring to disperse the nano-components, and then disperse under ultrasonic conditions for 3-5 minutes, and add water to make up to the preset water-cement ratio to obtain a mixed solution of the activator. Inspire the gelling material to be aged for more than 24 hours in the molding environment;

[0034] Preferably, the nano-component is hydrophilic nano-SiO 2 Or silica fume; wherein the hydrophilic nano-SiO 2 The mass percent of the alkali-activated gelling material is 0.5-3%, and the silica fume accounts for 3-9% of the ...

Embodiment 1

[0057] A kind of preparation method of alkali-activated gelling material that an embodiment of the present invention proposes, raw material comprises powder raw material, activator and nano component, and described activator is water glass solution, and the modulus of water glass solution is 2.0 , the solid content is 46.74%, and the dosage is 20%. The dosage is converted to Na 2 O, it is 6.813%. The mass ratio of water and powder raw materials in the activator is the preset water-cement ratio, which is 0.5; it includes:

[0058] 1) The nanometer component is silica fume, and the median particle size d(0.5) is 200nm. Add 9% silica fume to the activator, fully disperse and boil, cool to room temperature, and let it stand for 24 hours to obtain the activator mixed solution;

[0059] 2) Stir and mix the mixed solution of the powder raw material and the activator, cured for a short time under high temperature and humidity conditions (cured under saturated steam at 40°C for 24 h...

Embodiment 2

[0063] An embodiment of the present invention proposes a method for preparing an alkali-activated gelling material. The raw materials include powder raw materials, an activator and nano components, and the activator is 5% water glass solution and 5.11% sodium hydroxide solution , the converted Na in the activator 2 O is 6.813%. The mass ratio of water and powder raw materials in the activator is the preset water-cement ratio, which is 0.5; it includes:

[0064] 1) The nano-component is nano-SiO 2 , the particle size is less than 40nm. Add 3% nano-SiO to the activator, fully disperse and boil, add water to make up to the preset water-cement ratio, cool to room temperature, and let it stand for 24 hours to obtain the activator mixed solution;

[0065] 2) Stir and mix the mixed solution of the powder raw material and the activator, cured for a short time under high temperature and humidity conditions (cured under saturated steam at 60°C for 48 hours), removed the formwork and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com