Device and method for removing phosphite in waste water

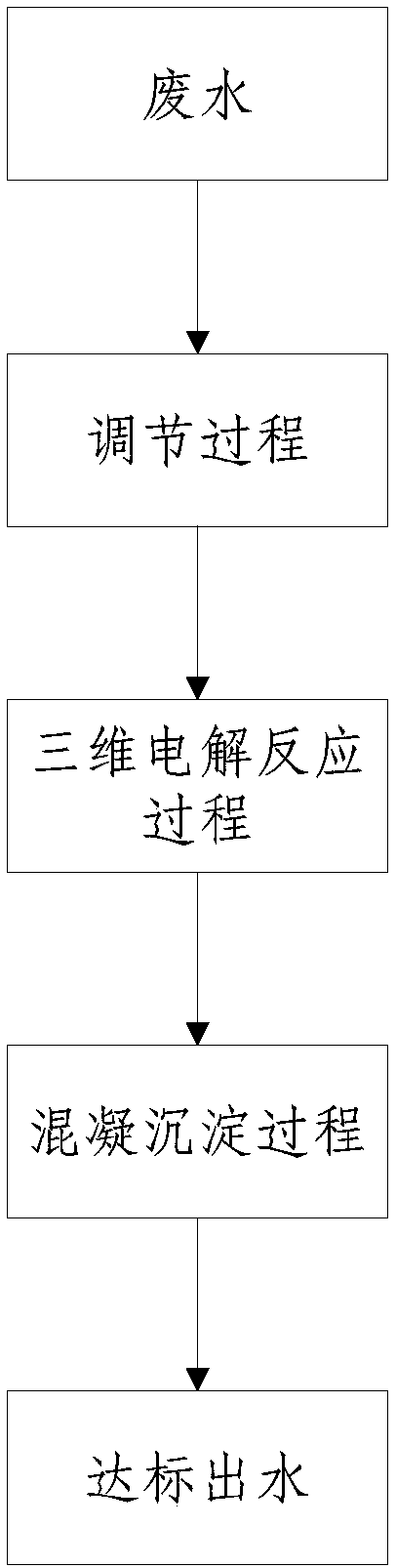

A phosphite and water distribution device technology, applied in chemical instruments and methods, water pollutants, water/sewage treatment, etc., can solve problems such as complex treatment processes, and achieve the effects of simple operation, cost reduction, and loose condition control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0056] The preparation method of the catalytic filler is: mix the iron-containing material, carbon-containing material, aluminum-containing material, magnesium-containing material, copper-containing material, trace metal, binder and pore-forming agent according to the proportion, add water and stir Aging is formed to form a mixture, and then the mixture is granulated by a granulator to obtain a catalytic filler body, the catalytic filler body is dried, then roasted, and finally cooled to obtain a catalytic filler. The added mass of the water is 3%-9% of the mass of the catalytic packing, the aging time is 10min-25min, the particle diameter of the catalytic packing blank is 20-40mm, and the catalytic packing blank The shape of the body is jagged, olive-shaped or spherical, etc., the drying temperature is 100°C-120°C, the drying time is 1h-2h, and the roasting temperature is 900°C-1200°C, The roasting time is 1h-3h.

[0057] The catalytic packing prepared by this method can pro...

Embodiment 1

[0075] Mix 45% iron fine powder, 23.8% graphite, 15% aluminum powder, 8% magnesium powder, 4% bentonite, 4% hydroxypropyl methylcellulose, 0.2% copper oxide and 5ppm palladium powder according to the proportion, and add mass Continue to stir and age 5% of the mass of the catalytic filler in water for 10 minutes, then granulate the mixture through a granulator to obtain a spherical filler body with a particle size of 20mm, and dry the filler body at 100°C 2h, and finally roasted at 1000°C for 3h under the protection of nitrogen, and the catalytic filler was obtained after natural cooling.

[0076] Use this catalytic packing for three-dimensional electrolytic reaction to treat the electroless nickel plating wastewater. The total phosphorus content in the test wastewater is 3867mg / L. The adjusted wastewater in the regulating tank is introduced into the three-dimensional electrolytic reaction tank, and the three-dimensional electrolytic reaction is aerated for 6 hours. After the t...

Embodiment 2

[0078] Mix 48% iron filings, 18.5% activated carbon, 18% kaolin, 7% magnesium chloride, 5% bentonite, 3% sodium borate, 0.5% copper oxide and 7ppm manganese powder according to the proportion, and the added mass is 6% of the mass of the catalytic filler Continue to stir and age the mixture for 15 minutes, and then granulate the mixture through a granulator to obtain a spherical filler body with a particle size of 25mm. The filler body is dried at 100°C for 2 hours, and finally the filler body is dried under the protection of nitrogen. Calcined at 1010°C for 2 hours, and cooled naturally to obtain the catalytic filler.

[0079] Use this catalytic packing for three-dimensional electrolytic reaction to treat electroless nickel plating wastewater. The total phosphorus content in the test wastewater is 2280mg / L. The adjusted wastewater in the regulating tank is introduced into the three-dimensional electrolytic reaction tank, and the three-dimensional electrolytic reaction is aerate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com