Support mechanism of crane

A technology of supporting mechanism and crane, which is applied in the direction of bottom supporting structure, hoisting equipment braking device, load hanging components, etc., which can solve the problems of increased volume and weight of cranes, insufficient flexibility and convenience, and prone to warping of legs, etc. , to achieve reasonable structure, increase convenience and flexibility, improve structural strength and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions of the present invention will be described in detail below in conjunction with embodiments. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and therefore are only examples, rather than limiting the protection scope of the present invention.

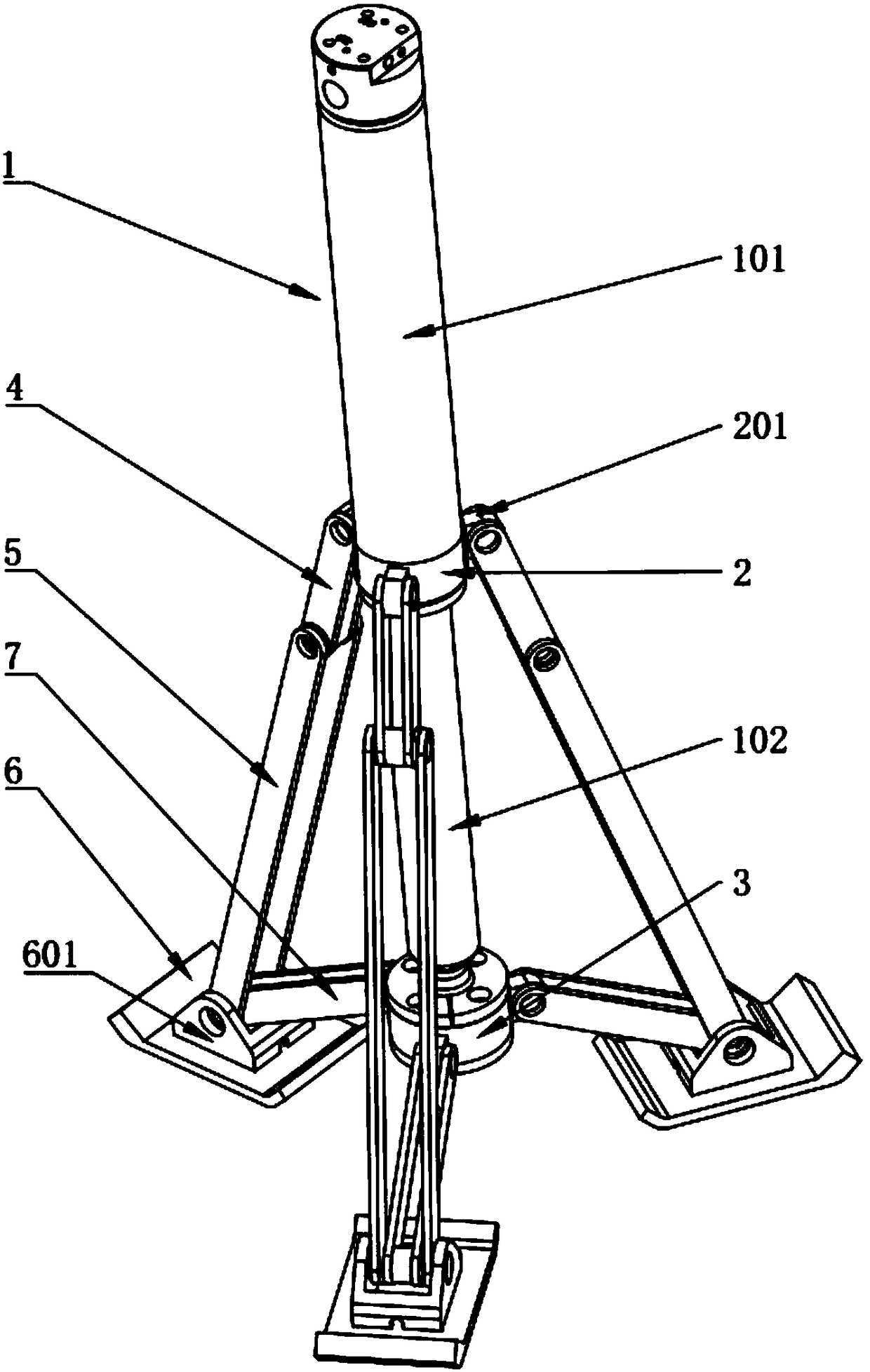

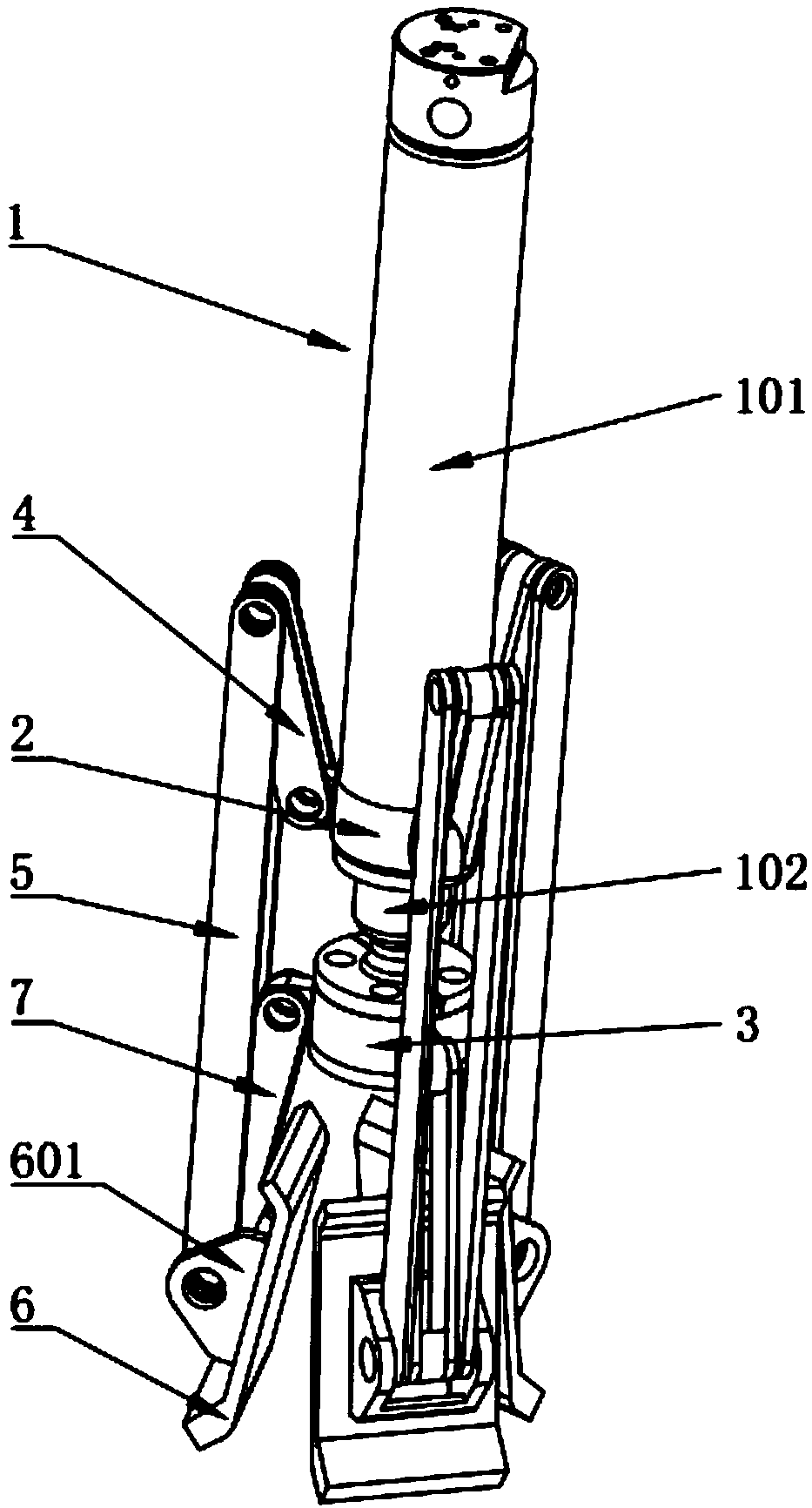

[0030] like Figure 1-2 As shown, a crane support mechanism includes a support cylinder 1, a cylinder barrel 101 of the support cylinder 1 is provided with a rotating sleeve 2, and a piston rod 102 of the support cylinder 1 is connected with a universal support seat 3;

[0031] A number of first connecting rods 4 are hinged on the upper ring of the rotating shaft sleeve 2, and the ends of the first connecting rods 4 are hinged with a second connecting rod 5, and the ends of the second connecting rods 5 are hinged on the side-weight foot plate 6;

[0032] The upper ring of the universal support base 3 is hinged with a third connecting rod 7, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com