Car condenser header main piece prefabricating tool

A condenser and pre-assembly technology, which is applied in the field of pre-assembly tooling for the main piece of the automobile condenser header, can solve the problem of high skill requirements for workers, the inability to ensure the accuracy and consistency of the installation position, and the long time for assembly and debugging of automobile condensers and other problems, to achieve the effect of reducing product unqualified problems, saving debugging time, and saving mold change time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

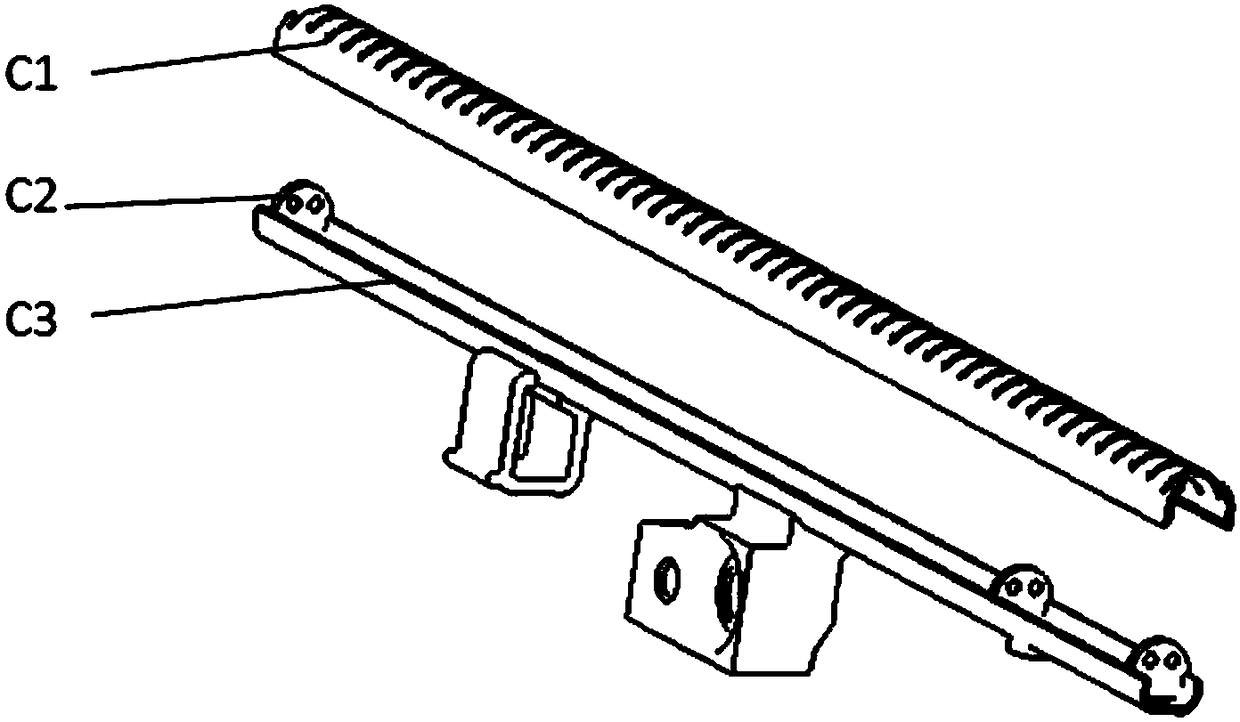

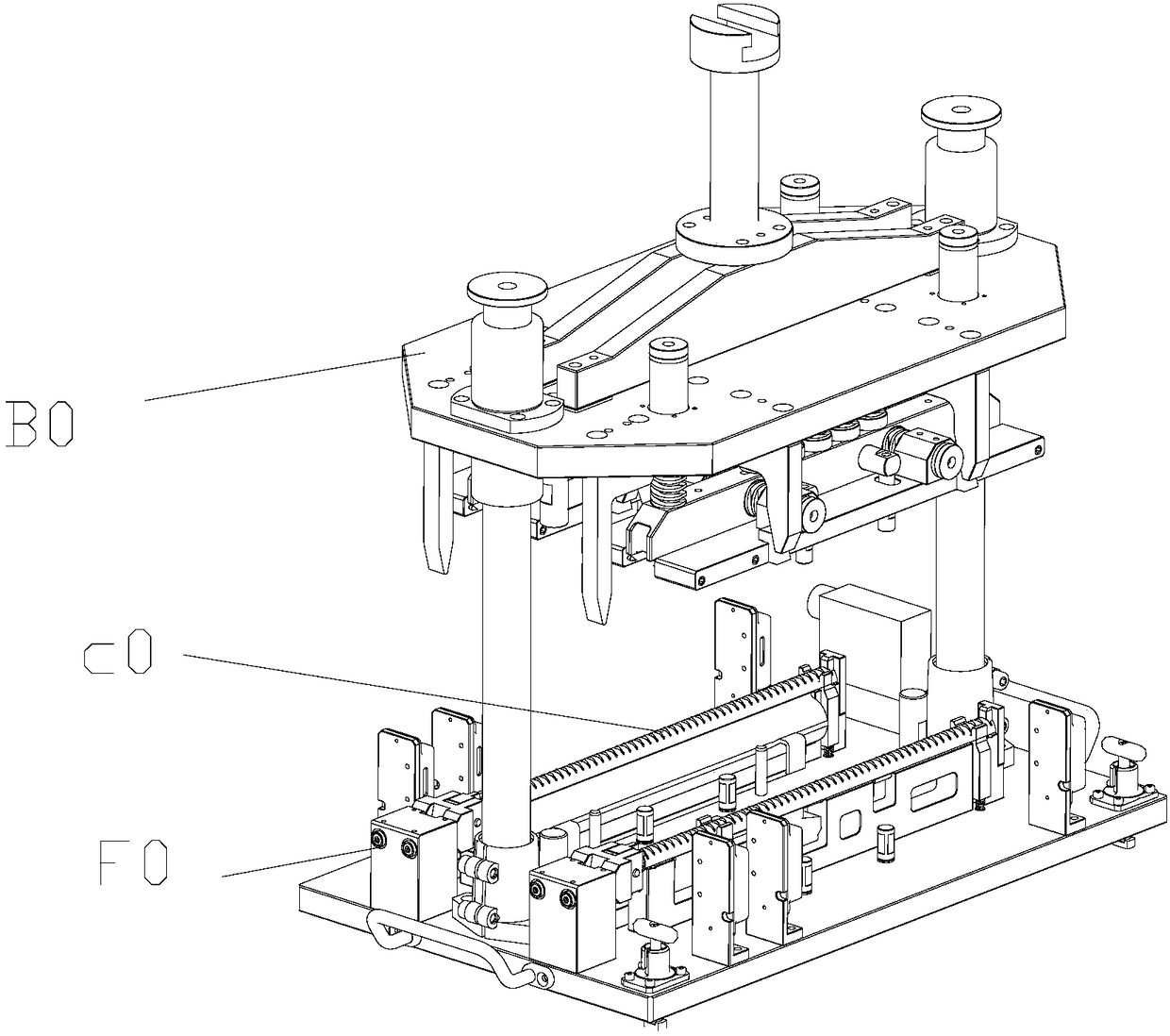

[0027] Such as Figure 1 to Figure 6 As shown, the tooling provided by the present invention is mainly used to assemble the three types of parts of the main piece C1, the spacer C2 and the cover assembly C3 of the condenser header into a header assembly, and the header pre-assembly tooling The main structure includes upper mold B0 and lower mold F0. The upper mold B0 and the lower mold F0 are connected and positioned by two main pillars B2.

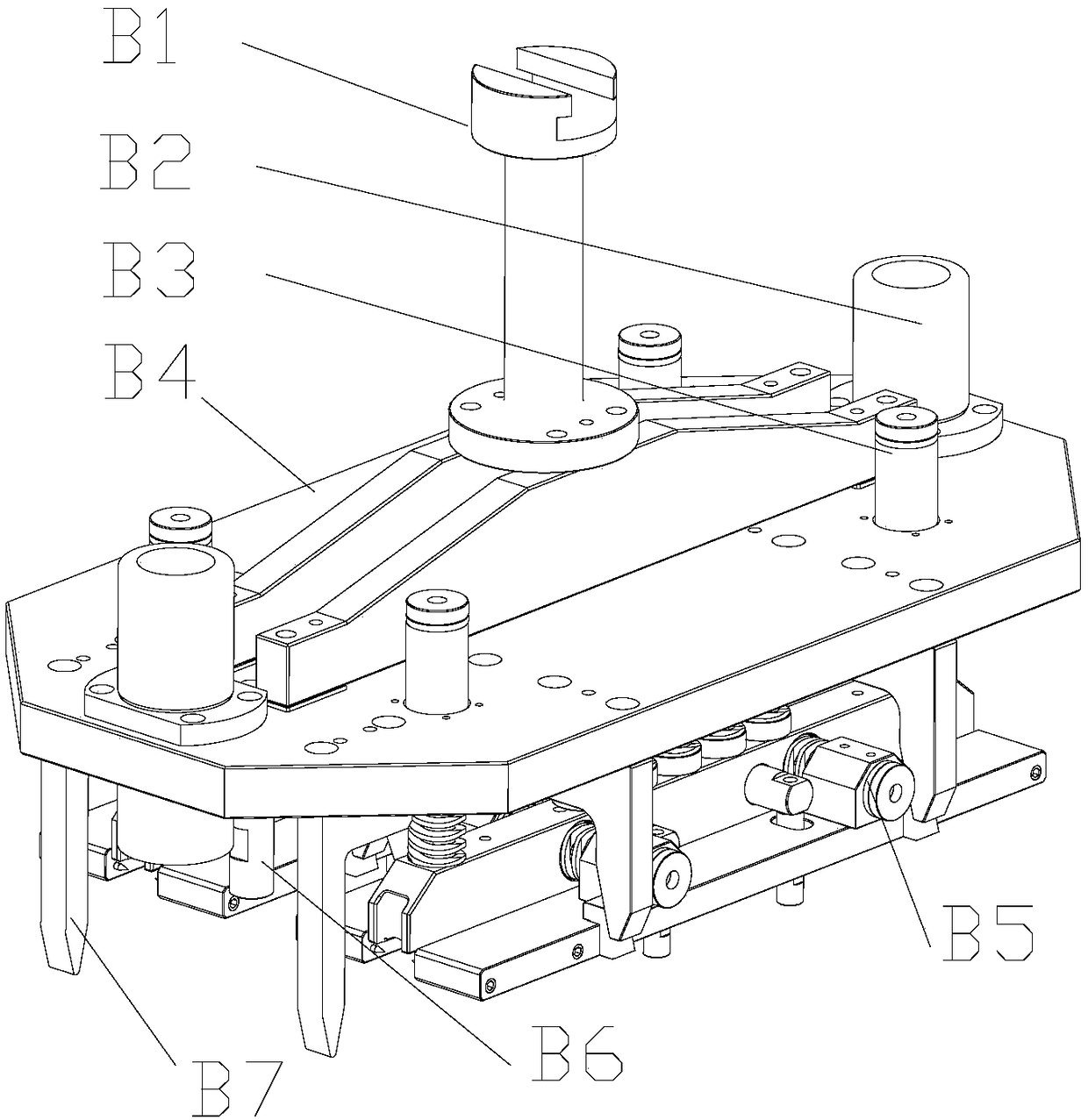

[0028] The upper mold B0 includes the tooling interface B1, the main pillar B2, the sub-guiding pillar B3, the upper mold base plate B4, the horizontal stamping thimble mechanism B5, the main limit column B6, and the upper mold tilting mechanism B7. The function of the tooling interface B1 is to be connected with the equipment. It is connected with the cylinder to provide up and down power for the tooling. The tooling interface also has a quick change function. The leading sleeve B2 is used to cooperate with the leading column B2 to conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com