Lithium ion adsorbent as well as preparation method and application thereof

A technology of deionized water and vermiculite, which is applied in the field of economical environmental protection and resource utilization, can solve the problems of reducing the regeneration efficiency of adsorbents, deep embedment of adsorption sites, unfavorable lithium ion adsorption and desorption, etc., and is easy to promote in industrialization , simple operation, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] 1) Pretreatment of vermiculite

[0044] ① Nitric acid steam treatment of vermiculite

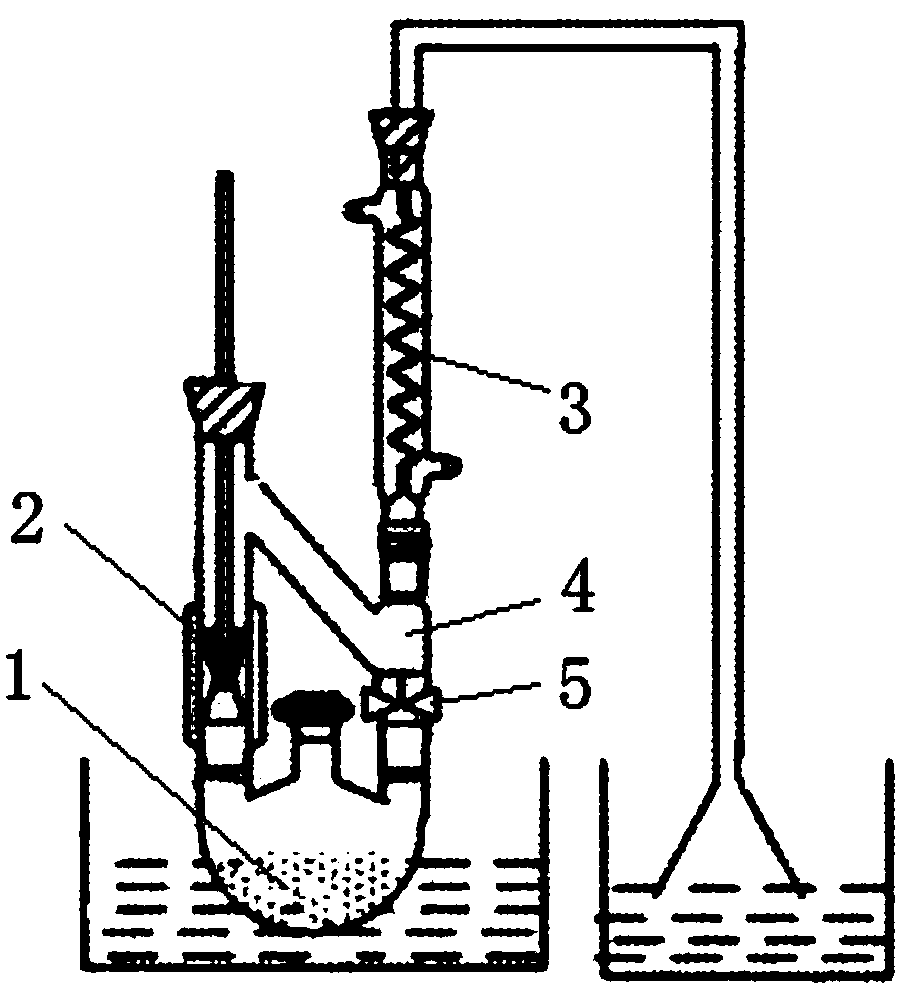

[0045] Weigh 1.5 g of crushed vermiculite with a particle size of less than 150 μm and put it into a self-assembled gas reflux device, add 150 mL of concentrated nitric acid, and heat it in an oil bath at 140°C for 2 hours.

[0046] Such as figure 1As shown, 1 place is concentrated nitric acid, 2 places are vermiculite, and 5 places are pistons. After heat treatment, the nitric acid turns into steam and volatilizes to 2 places. After the vermiculite is acid-treated, it volatilizes and enters 4 through the branch pipe. The nitric acid vapor becomes liquid droplets through the condensation pipe 3 and gathers at the bottom. Adjust the piston 5, Realize the recovery and utilization of nitric acid.

[0047] ②Put the vermiculite treated with nitric acid vapor into a beaker filled with 80mL of water, place it in an ultrasonic device, and conduct ultrasonic treatment for 3 hours. Then was...

Embodiment 2

[0065] 1) Pretreatment of vermiculite

[0066] ① Nitric acid steam treatment of vermiculite

[0067] Weigh 1.5 g of crushed vermiculite with a particle size of less than 150 μm and put it into a self-assembled gas reflux device, add 150 mL of concentrated nitric acid, and heat it in an oil bath at 140°C for 2 hours.

[0068] ②Put the vermiculite treated with nitric acid vapor into a beaker filled with 100mL of water, place it in an ultrasonic device, and conduct ultrasonic treatment for 3 hours. Then wash to neutral and dry for later use. According to BET analysis, the specific surface area of vermiculite will increase correspondingly with the increase of treatment time.

[0069] 2) Preparation of lithium ion imprinted polymer

[0070] ① Add 10g of lithium nitrate, 7g of crown ether and 150μL of methacrylic acid into 150mL of a mixed solution of methanol and dimethylformamide, the volume ratio of methanol to dimethylformamide is 15:1, and then put it Stir in a 25°C water...

Embodiment 3

[0074] 1) Pretreatment of vermiculite

[0075] ① Nitric acid steam treatment of vermiculite

[0076] Weigh 1.5 g of crushed vermiculite with a particle size of less than 150 μm and put it into a self-assembled gas reflux device, add 150 mL of concentrated nitric acid, and heat it in an oil bath at 140 ° C for 8 hours.

[0077] ②Put the vermiculite treated with nitric acid vapor into a beaker filled with 100mL of water, and place it in an ultrasonic device for ultrasonic treatment for 10 hours. Then wash to neutral and dry for later use. According to BET analysis, the specific surface area of vermiculite will increase correspondingly with the increase of treatment time.

[0078] 2) Preparation of lithium ion imprinted polymer

[0079] ①Add 0.1g of lithium nitrate, 0.02g of crown ether and 100μL of methacrylic acid into 40mL of a mixed solution of methanol and dimethylformamide, the volume ratio of methanol to dimethylformamide is 15:1, and then add It was placed in a 25°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com