Novel long-shaft magnetic pump type reactor

A reactor and magnetic pump technology, applied in the field of new long-axis magnetic pump reactors, can solve the problems of uneven mixing of gas-liquid-solid three-phase, and achieve uniform gas-liquid-solid three-phase mixing and gas-liquid-solid three-phase mixing. Good effect, safe and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

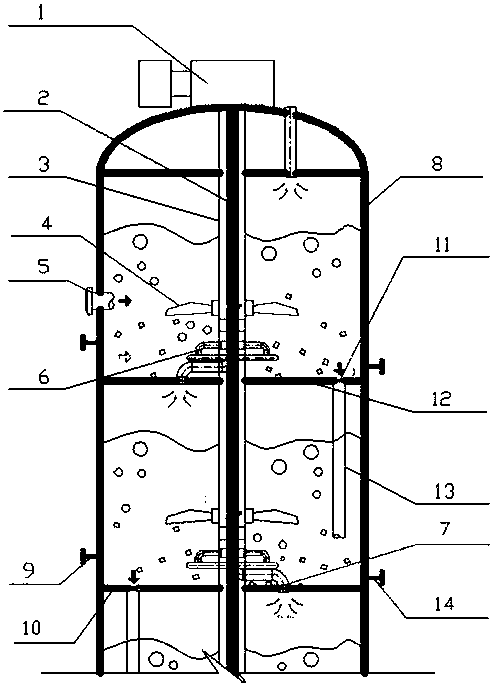

[0025] A new type of long-axis magnetic pump reactor, such as figure 1 As shown in the figure, a long shaft runs through the reactor, the long shaft is wrapped by a long sleeve, and a bearing is installed inside to completely isolate the shaft and the bearing from the outer medium. The principle of the magnetic pump is used to immerse the blade in the medium. Coupled with the shaft to achieve the effect of stirring, the gas riser is arranged on each tray in the reactor, the air inlet of the gas riser is set on one side of the long axis of the reactor, and a gas distributor is connected to the upper part of the gas riser, and the center of the gas distributor falls on the side of the long axis of the reactor. On the long axis, the gas phase from the lower tray is evenly sprayed into the liquid-solid mixture on the tray through the gas distributor. Each tray is provided with liquid phase inlet and outlet facilities, and liquid phase inlets are set on both sides of the tray. and ...

Embodiment 2

[0029] A new type of long-axis magnetic pump reactor, such as figure 2 As shown in the figure, a long shaft runs through the reactor, the long shaft is wrapped by a long sleeve, and a bearing is installed inside to completely isolate the shaft and the bearing from the outer medium. The principle of the magnetic pump is used to immerse the blade in the medium. Coupled with the shaft to achieve the effect of stirring, the gas riser is arranged on each tray in the reactor, the air inlet of the gas riser is set on one side of the long axis of the reactor, and a gas distributor is connected to the upper part of the gas riser, and the center of the gas distributor falls on the side of the long axis of the reactor. On the long axis, the gas phase from the lower tray is evenly sprayed into the liquid-solid mixture on the tray through the gas distributor. Each tray is provided with liquid phase in and out facilities, and a downcomer is set on the tray. The liquid phase flows from the ...

Embodiment 3

[0033] According to the conditions and steps described in Example 1, the distance between two adjacent trays is H, the inner diameter of the tower is D, and H is 400mm; The holes are equally spaced and evenly distributed; the ratio of the diameter c of the gas riser to the inner diameter D of the tower is 0.1, the distance between the center of the inlet of the gas riser and the center of the tray is 0.2D, and the ratio of the diameter d of the downcomer to the inner diameter D of the tower is 0.25, the distance between the center line of the downcomer and the center of the tray is 0.45D, and the ratio of the height h of the downcomer to the distance H between two adjacent trays is 0.7. The gas distributor is a double-ring type gas distributor, the ratio of the outer pipe diameter a of the double-ring type gas distributor to the inner diameter D of the tower is 0.5, the ratio of the inner pipe diameter b to the inner diameter D of the tower is 0.4, and the center of the double-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com