Preparation method of flat plate microfiltration membrane for biological detection

A microbial detection and microfiltration membrane technology, applied in chemical instruments and methods, membranes, ultrafiltration, etc., can solve the problems of weak anti-pollution ability, large adsorption capacity, low flux, etc., and achieve strong retention capacity and high separation efficiency , excellent structural properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

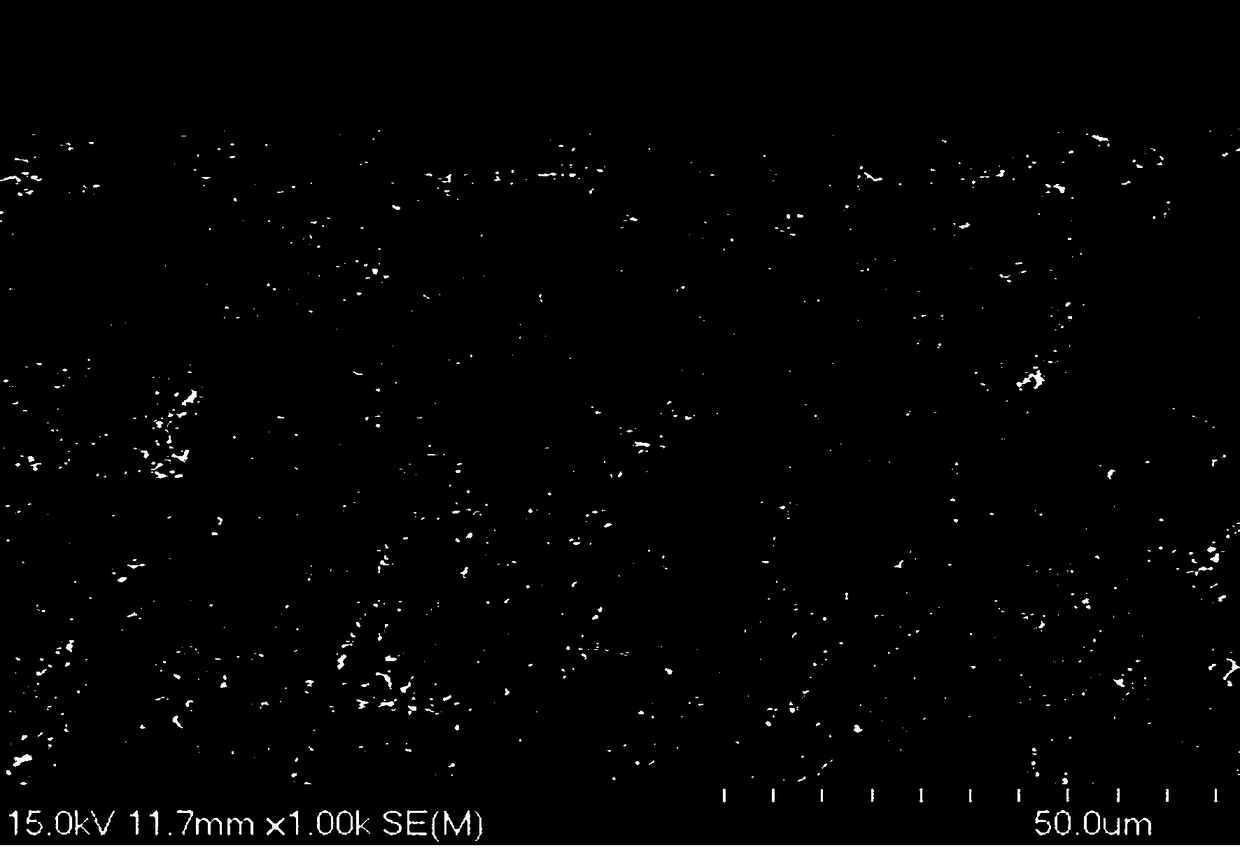

Image

Examples

Embodiment 1

[0024] A method for preparing a flat microfiltration membrane for biological detection, comprising the following steps,

[0025] 1) Mix the components of the casting solution evenly, and set aside; the composition and weight percentage of the casting solution are: polyethersulfone 12.5%, sulfonated polyethersulfone 1.5%, polyvinylpyrrolidone-k30 11%, diethylene glycol 30% %, N-methylpyrrolidone 45%;

[0026] 2) Put the casting solution in step 1) to stand still for defoaming: put the casting solution in an airtight container at 30° C. to stand still for defoaming;

[0027] 3) Steam-induced film formation: Take a clean glass plate and place it horizontally on the scraper machine, cast the casting solution on one end of the glass plate, spread the casting solution evenly on the glass plate with a 150 μm scraper, stay for 90 seconds, and air The water vapor in the film initially contacts with the casting solution, exchanges with the solvent, and a small phase separation occurs. ...

Embodiment 2

[0029] A method for preparing a flat microfiltration membrane for biological detection, comprising the following steps,

[0030] 1) Mix the components of the casting solution evenly, and set aside; the composition and weight percentage of the casting solution are: polyethersulfone 11%, sulfonated polyethersulfone 2%, polyvinylpyrrolidone-k30 12%, diethylene glycol 20% %, N-methylpyrrolidone 55%;

[0031] 2) Put the casting solution in step 1) to stand still for defoaming: put the casting solution in an airtight container at 30° C. to stand still for defoaming;

[0032] 3) Steam-induced film formation: Take a clean glass plate and place it horizontally on a film scraper, cast the casting solution on one end of the glass plate, spread the casting solution evenly on the glass plate with a 150 μm scraper, stay for 60 seconds, and air The water vapor in the liquid is initially in contact with the casting liquid, exchanges with the solvent, and a small phase separation occurs. Then...

Embodiment 3

[0034] A method for preparing a flat microfiltration membrane for biological detection, comprising the following steps,

[0035] 1) Mix the components of the casting solution evenly, and set aside; the composition and weight percentage of the casting solution are: polyethersulfone 13.5%, sulfonated polyethersulfone 0.5%, polyvinylpyrrolidone-k30 9%, diethylene glycol 30% %, N-methylpyrrolidone 47%;

[0036] 2) Put the casting solution in step 1) to stand still for defoaming: put the casting solution in an airtight container at 30° C. to stand still for defoaming;

[0037] 3) Steam-induced film formation: Take a clean glass plate and place it horizontally on the scraper machine, cast the casting solution on one end of the glass plate, spread the casting solution evenly on the glass plate with a 150 μm scraper, stay for 120s, and air The water vapor in the liquid is initially in contact with the casting liquid, exchanges with the solvent, and a small phase separation occurs. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com