Cooling device and method for preparation of HDI by gas phase process

A cooling device and gas phase method technology, applied in the chemical industry, can solve the problems of large temperature difference and easy blockage of the system, blockage of the tail gas system, poor cooling effect, etc., and achieve the effect of slowing down the blockage of the tail gas pipeline, saving energy, and prolonging the normal production time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

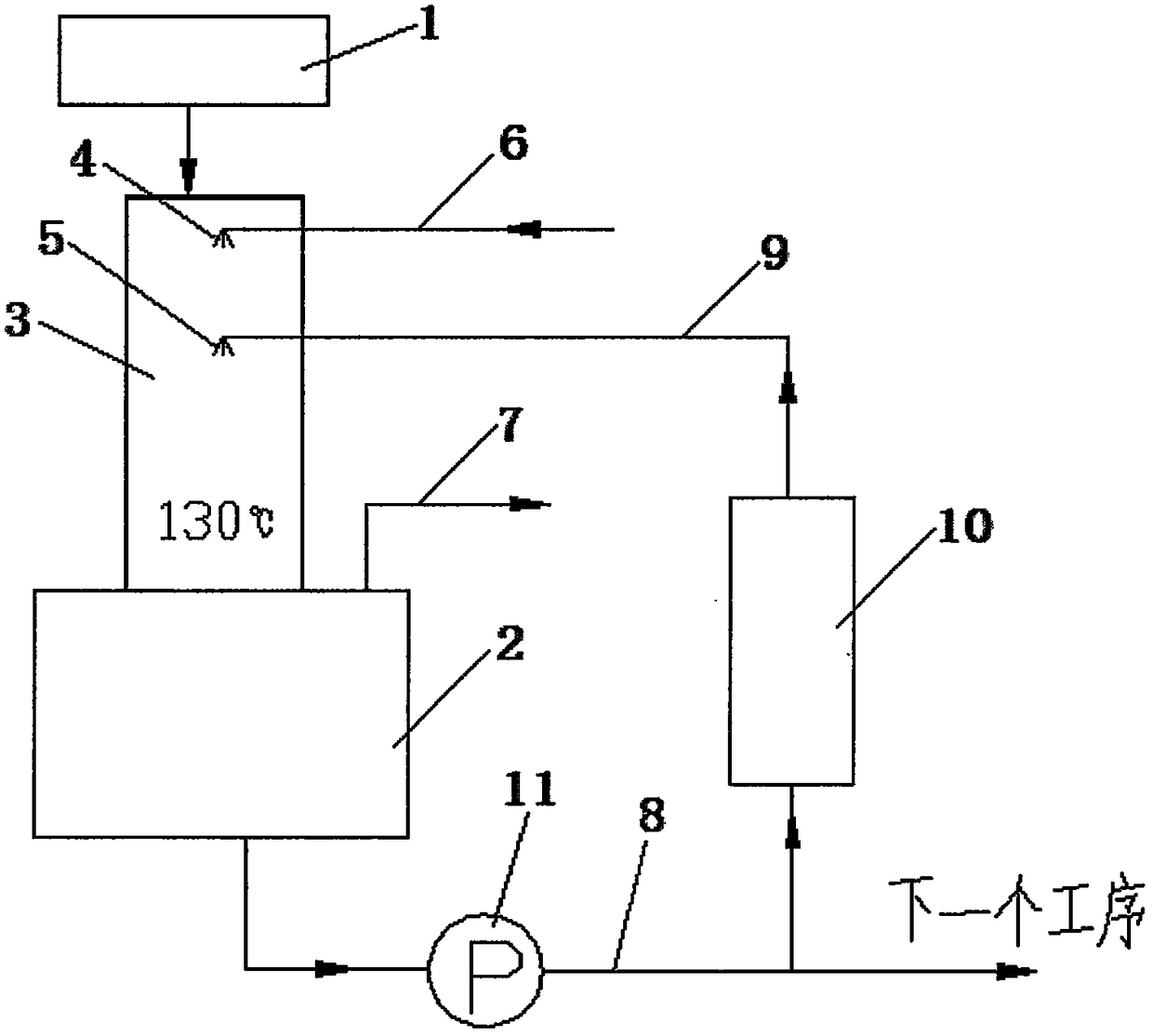

[0015] In order to allow those skilled in the art to understand the present invention more clearly and intuitively, the present invention will be further described below in conjunction with the accompanying drawings.

[0016] Such as figure 1 Shown is a preferred embodiment of the invention.

[0017] A cooling device for preparing HDI by a gas phase method, comprising a spray condensation area 3 arranged between a reactor 1 and a reaction collector 2, a first nozzle 4 is arranged above the spray condensation area 3, and a first nozzle 4 is arranged below the first nozzle 4 There is a second nozzle 5, and the first nozzle 4 is connected with a chlorobenzene delivery pipe 6, and chlorobenzene is sprayed out in the spray condensation zone 3 through the first nozzle 4, and the isocyanate prepared by the reactor 1 is cooled and absorbed, so that the isocyanate and For the separation of other gaseous substances, the reaction collector 2 is provided with a gas outlet pipe 7 and a li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com