Dedusting filter element

A filter element and filter layer technology, applied in the field of air filter components, can solve problems such as reducing production efficiency, shortening service life, and being easily blown flat, and achieving the effects of increasing service life, improving production efficiency, and reducing the number of blowback times.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following content is a further detailed description of the present invention in conjunction with specific preferred embodiments. It cannot be determined that the specific implementation of the present invention is only limited to these descriptions. The features in the examples can be combined with each other.

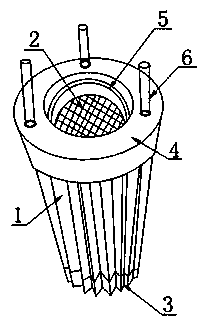

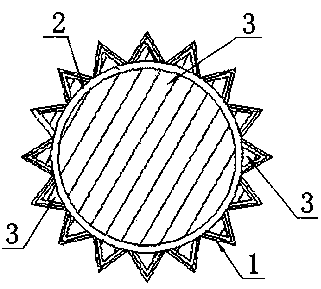

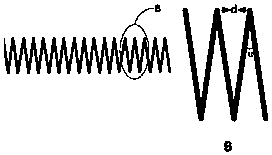

[0017] combine figure 1 , figure 2 and image 3 As shown, a dust removal filter element of the present invention mainly includes a V-shaped continuous pleated filter layer 1 and a supporting protective layer 2 located inside the V-shaped continuous pleated filter layer. The new dust removal filter element also includes an iron injection bottom 3 and an iron injection head. 4. The iron injection bottom is glued to the inner side of one end of the V-shaped continuous pleated filter layer, which is in the shape of a gear; the iron injection head is glued to the other end of the V-shaped continuous pleated filter layer, and wraps the V-shaped continuous pleat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com