Backwashing solid-liquid separation device

A solid-liquid separation and backwashing technology, applied in filtration separation, separation methods, fixed filter element filters, etc., can solve problems such as blockage or damage of sewage pumps, flushing dead corners at connections, and accumulation of debris, etc. The effect of improved life, strong practicability and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be specifically described below in conjunction with the accompanying drawings and embodiments.

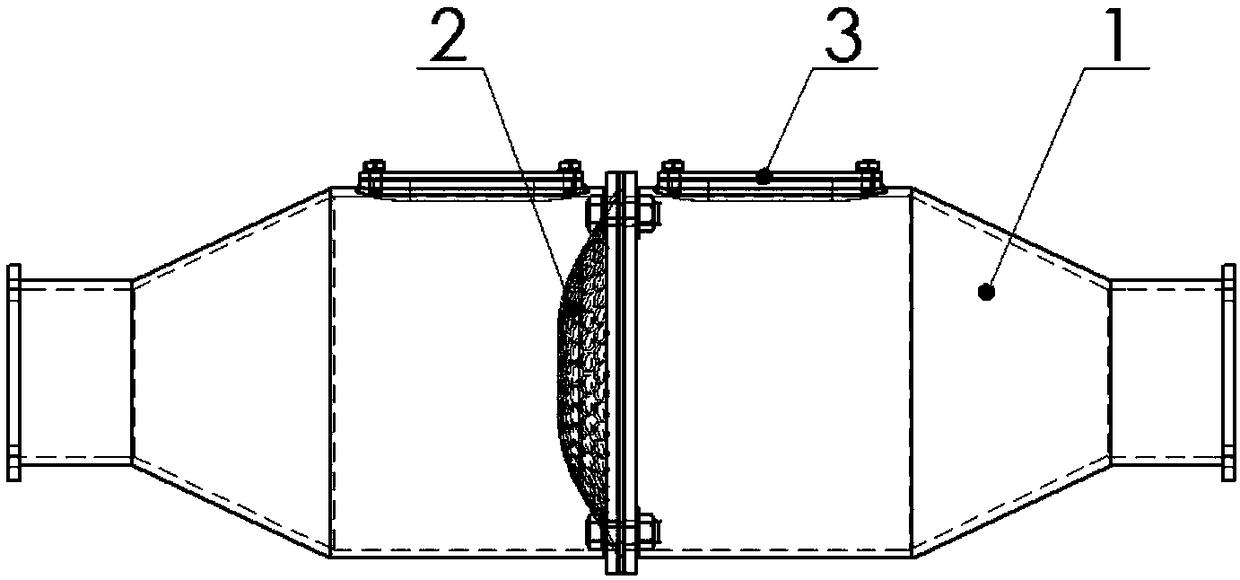

[0018] figure 1 Shown is the structural representation of the present invention.

[0019] The invention provides a solid-liquid separation device for backwashing, which includes two tempered glass cylinders 1 , a filter screen 2 and two cleaning hole covers 3 .

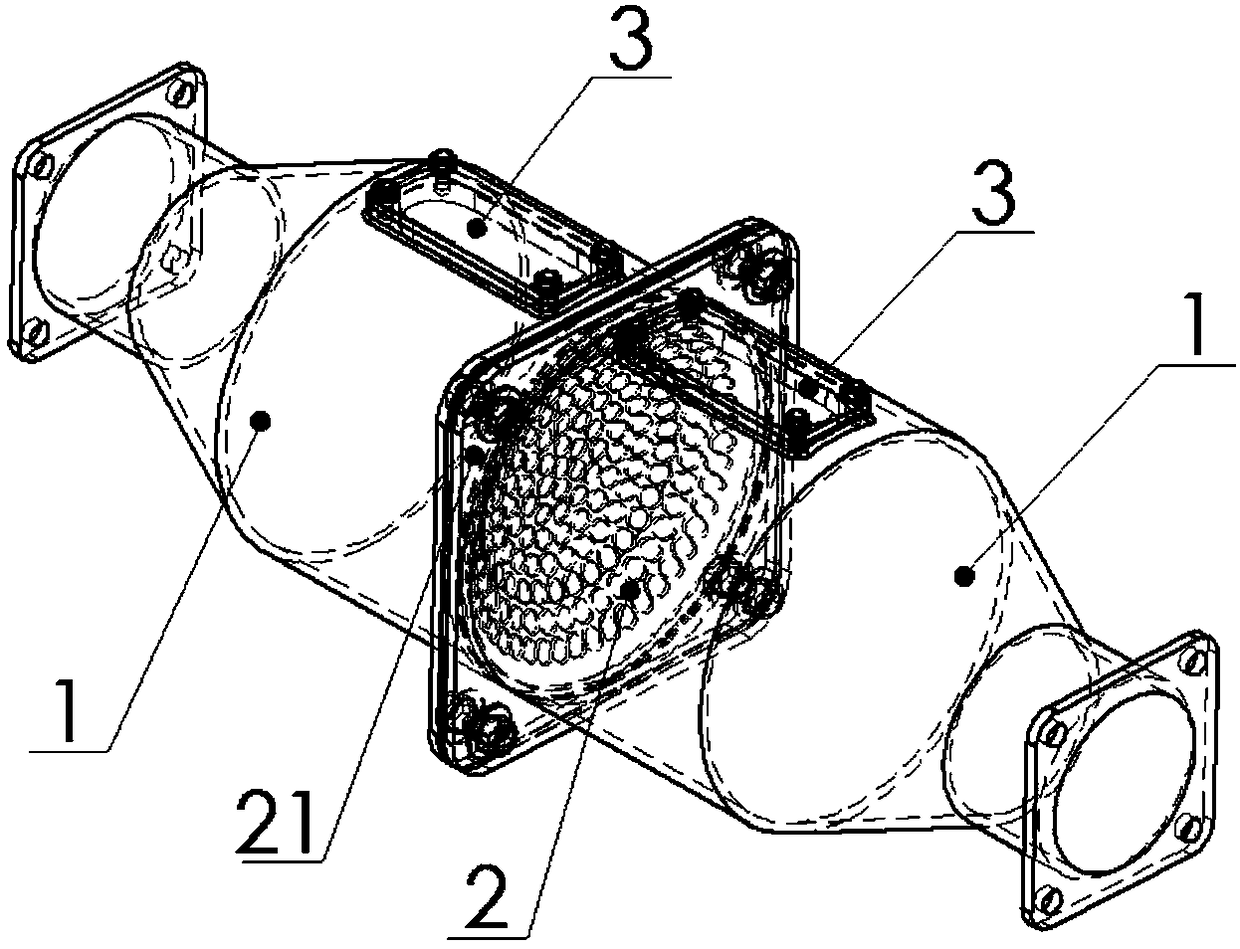

[0020] figure 2 Shown is a schematic diagram of structural decomposition of the present invention.

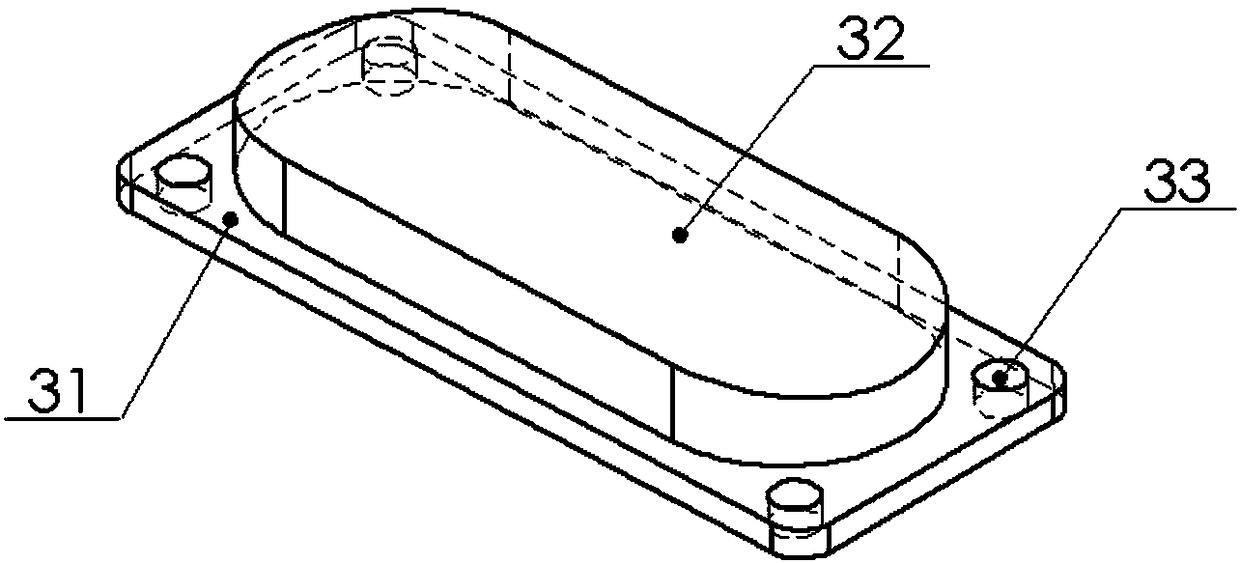

[0021] The tempered glass cylinder 1 includes a large end, a small end and a middle transition section, the ends of the large end and the small end are provided with flanges, the upper part of the large end is provided with cleaning holes, and the outer corners of the cleaning holes are provided with bolts Hole, the cleaning hole cover 3 is fixed on the cleaning hole by bolts.

[0022] Described filter screen 2 adopts tough and corrosion-resistant soft material to make, can change shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com